|

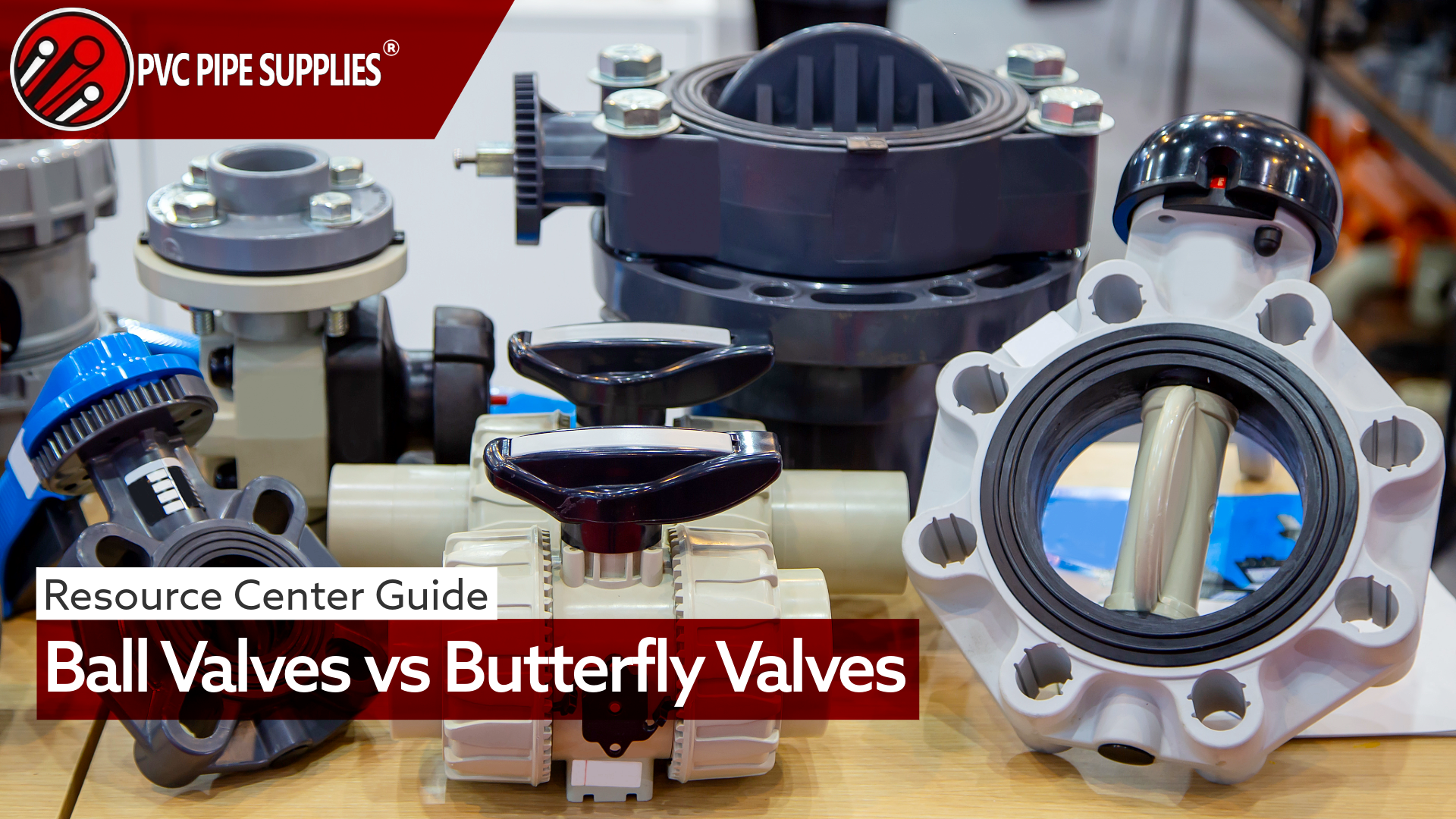

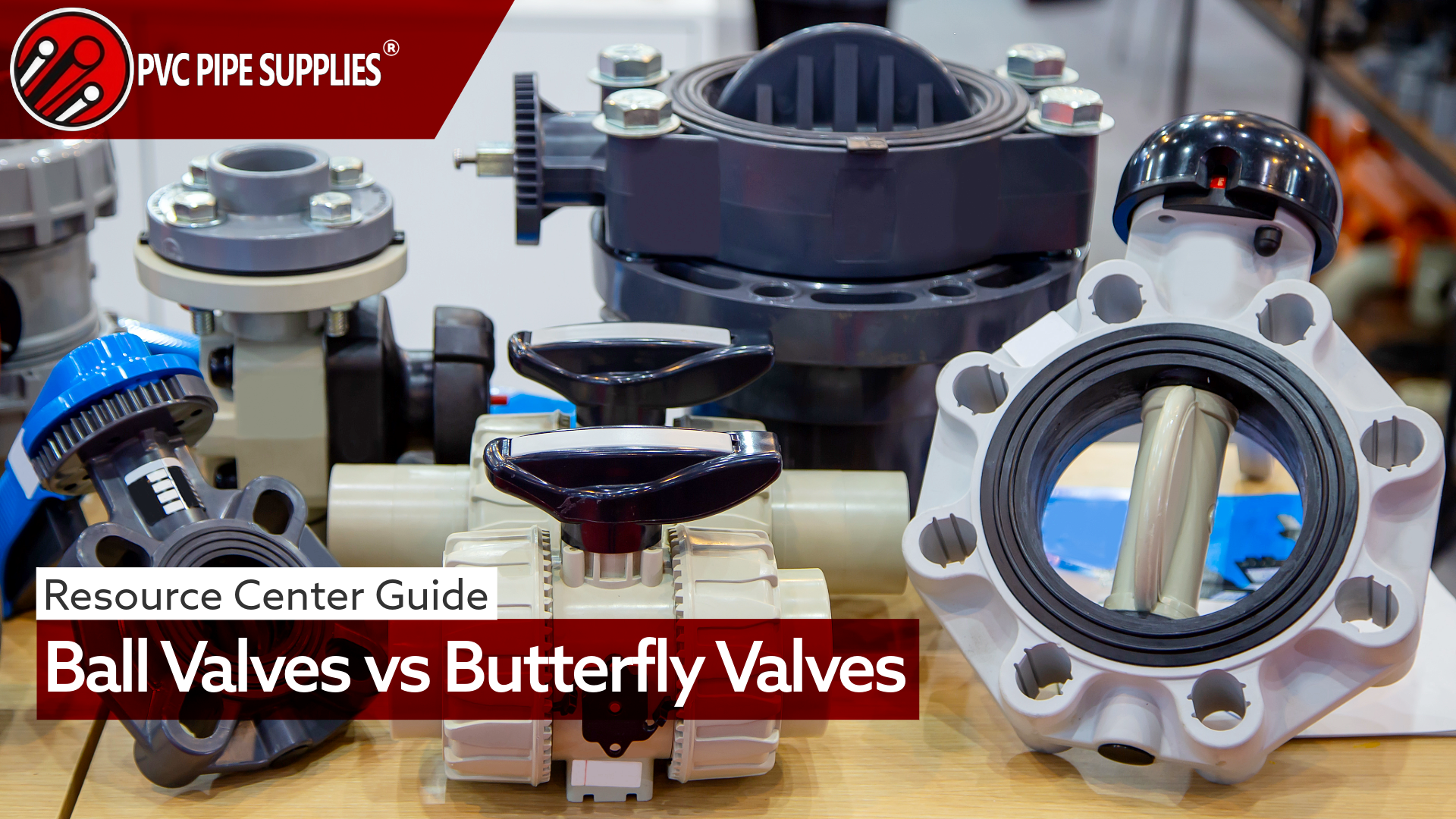

An unexpected valve failure during an emergency shutdown can bring operations to a grinding halt, leading to costly downtime and safety risks. In industries like municipal water systems or chemical processing, having the right valve isn’t just a choice but the key to safety, efficiency, and reliability during critical moments. When fluid flow needs precise control, the right valve can make all the difference between smooth operations and costly downtime. In the pipe valve market, two options consistently stand out for their versatility and effectiveness: ball valves and butterfly valves. Both are quarter turn rotary valves that have earned their place in commercial, industrial, and residential plumbing systems worldwide. Ball valves, featuring hollow rotating spheres, offer exceptional sealing capabilities and minimal pressure drop. Butterfly valves, featuring rotating discs that resemble a butterfly’s wings, offer lightweight construction and compact solutions for large scale applications. This article compares ball valves and butterfly valves and focuses on how their unique designs impact your operations. By understanding their differences, you'll be able to choose the valve that maximizes uptime, enhances system safety, and reduces maintenance costs. Whether you prioritize durability, ease of operation, or budget efficiency, this guide will help you make the decision that improves the reliability and performance of your pipelines and plumbing systems. |

An unexpected valve failure during an emergency shutdown can bring operations to a grinding halt, leading to costly downtime and safety risks. In industries like municipal water systems or chemical processing, having the right valve isn’t just a choice but the key to safety, efficiency, and reliability during critical moments. When fluid flow needs precise control, the right valve can make all the difference between smooth operations and costly downtime.

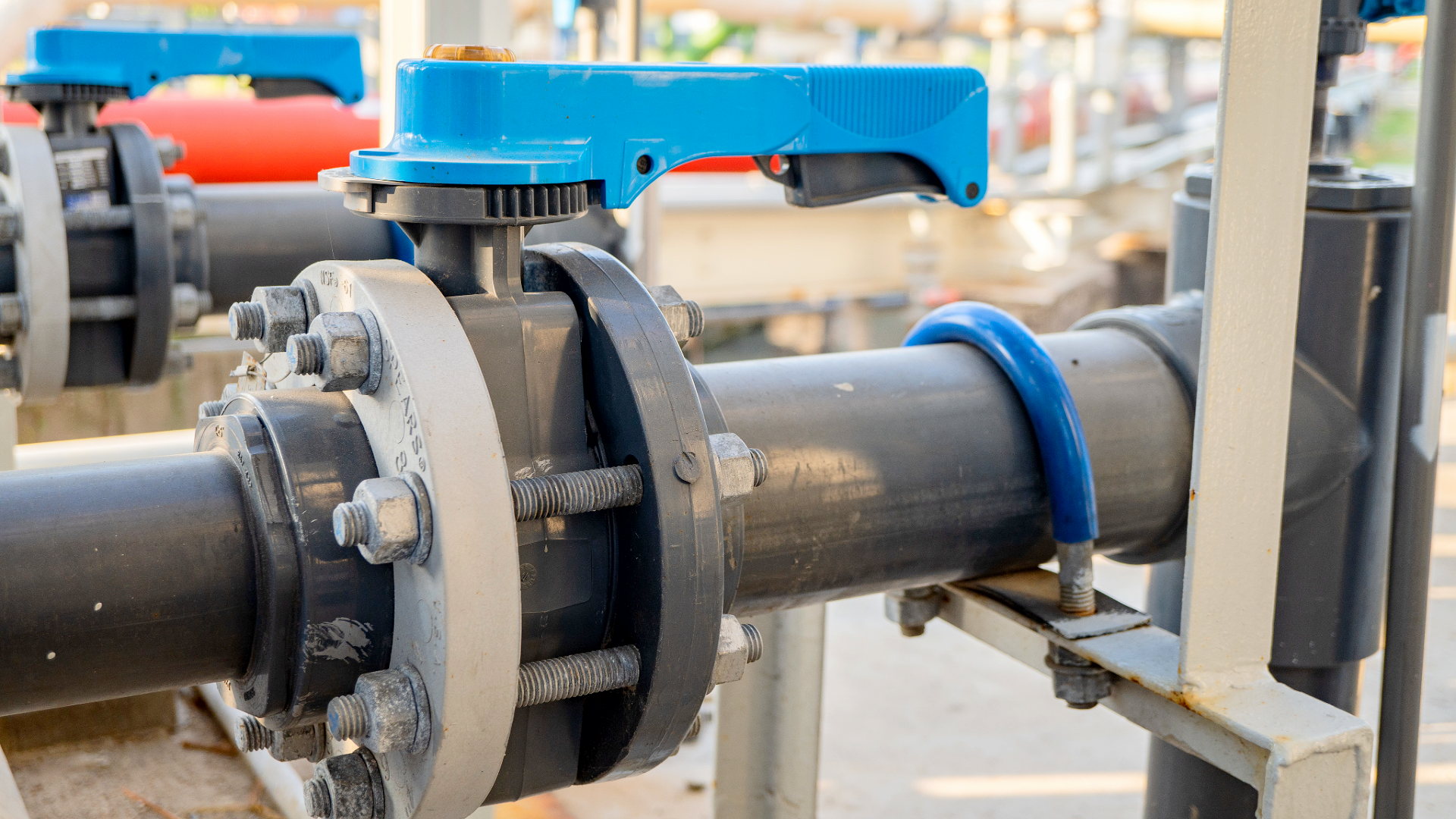

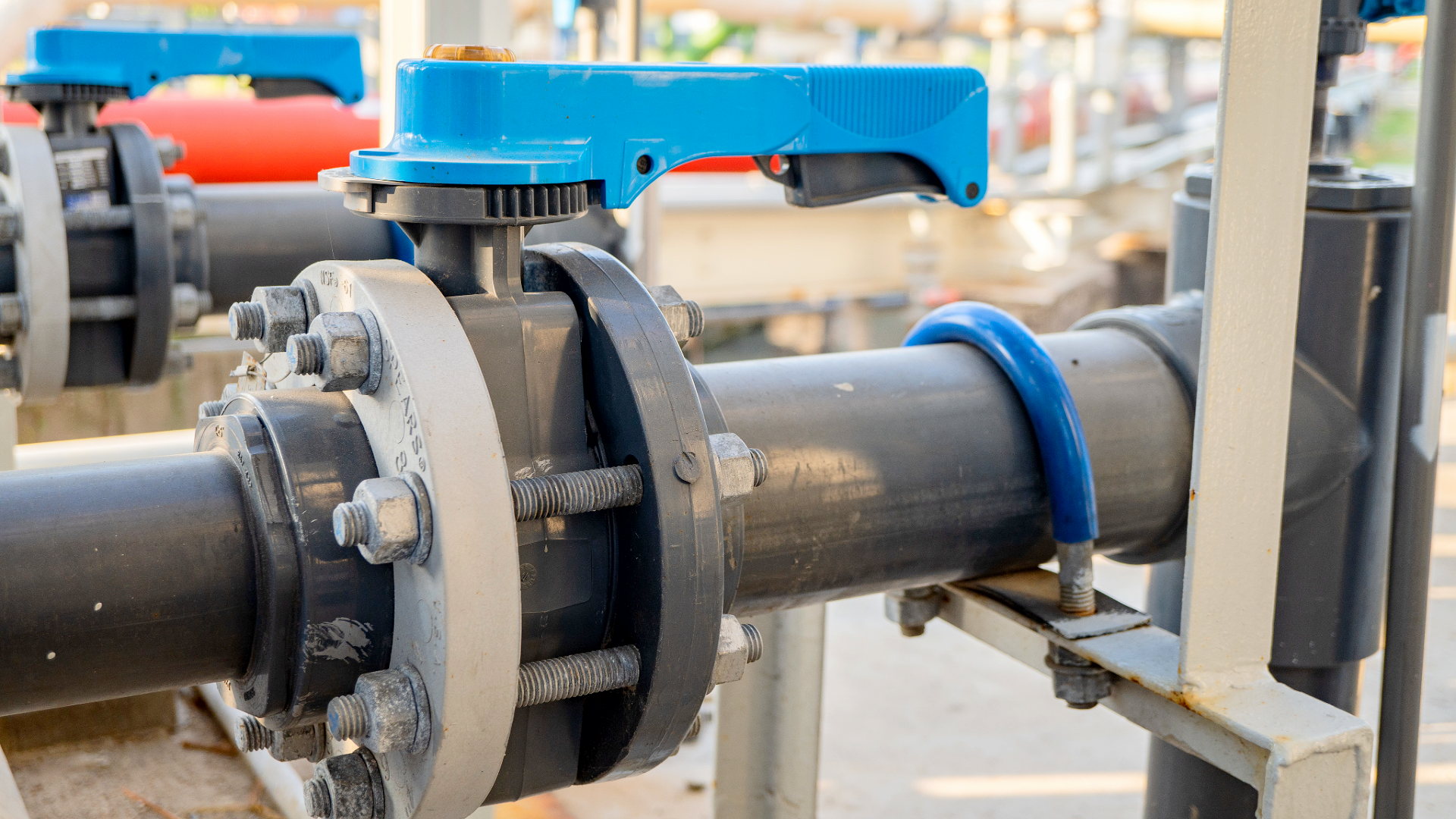

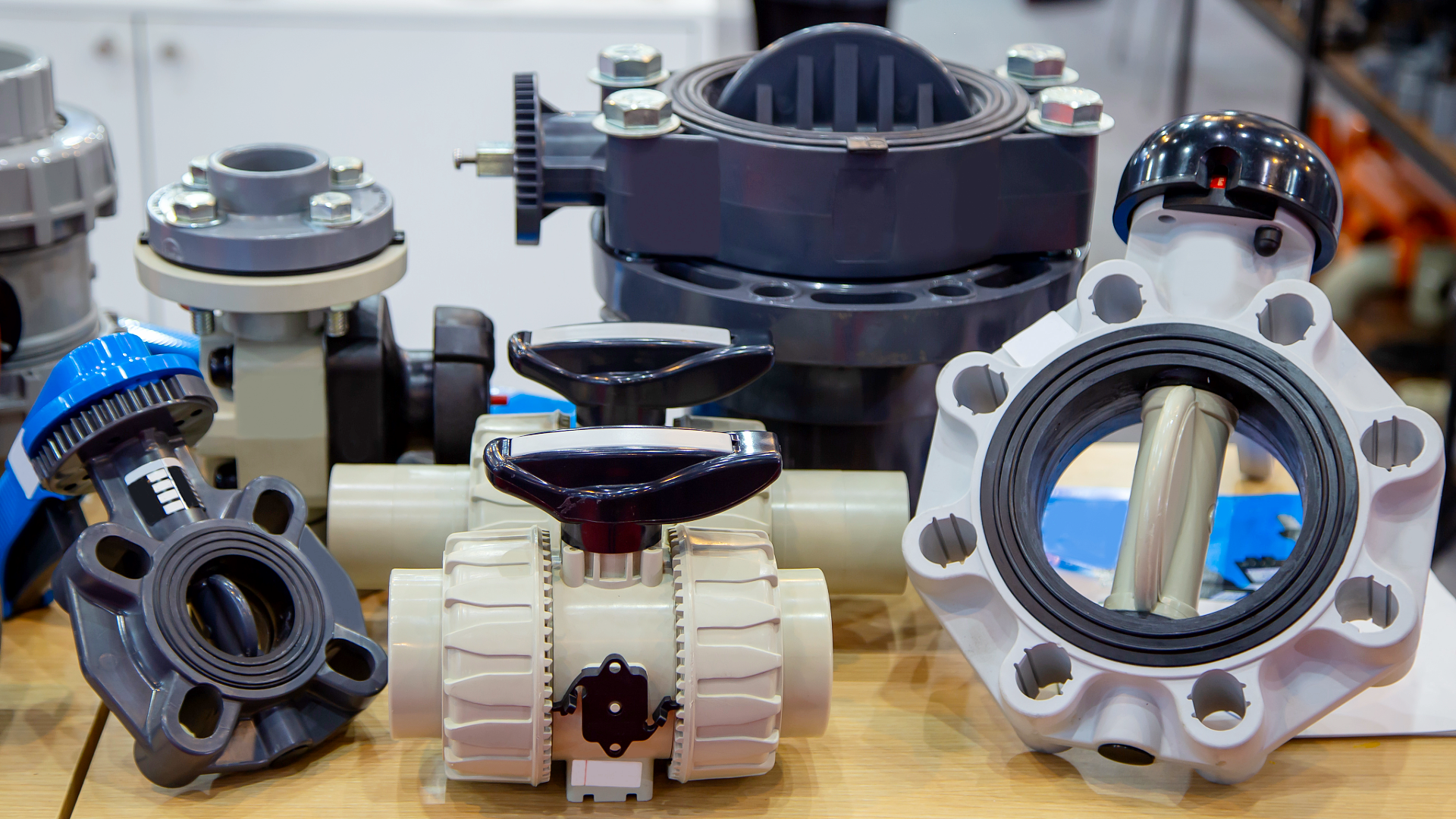

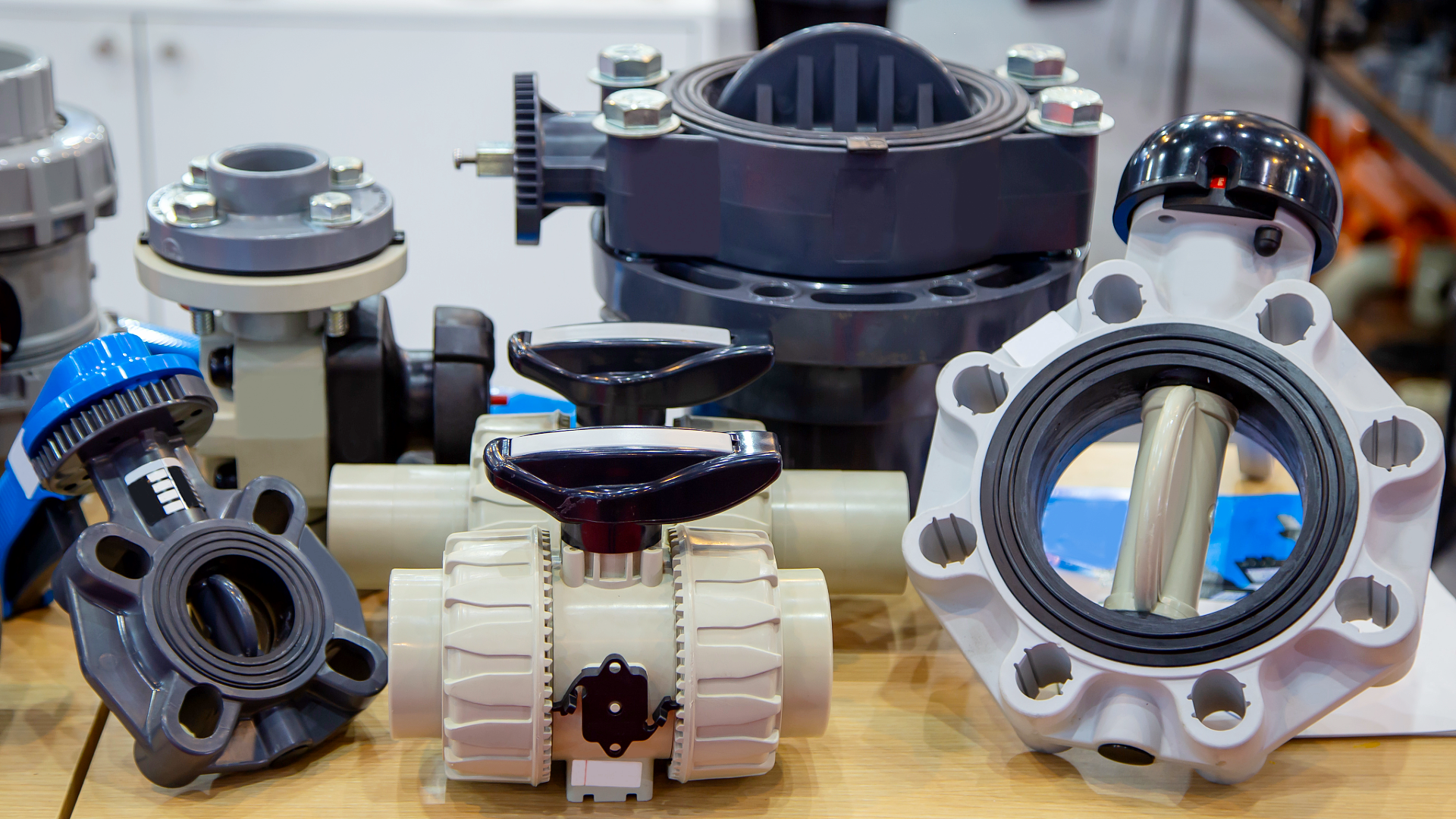

In the pipe valve market, two options consistently stand out for their versatility and effectiveness: ball valves and butterfly valves. Both are quarter turn rotary valves that have earned their place in commercial, industrial, and residential plumbing systems worldwide. Ball valves, featuring hollow rotating spheres, offer exceptional sealing capabilities and minimal pressure drop. Butterfly valves, featuring rotating discs that resemble a butterfly’s wings, offer lightweight construction and compact solutions for large scale applications.

This article compares ball valves and butterfly valves and focuses on how their unique designs impact your operations. By understanding their differences, you'll be able to choose the valve that maximizes uptime, enhances system safety, and reduces maintenance costs. Whether you prioritize durability, ease of operation, or budget efficiency, this guide will help you make the decision that improves the reliability and performance of your pipelines and plumbing systems.

What Are Ball Valves?

Definition and Mechanism

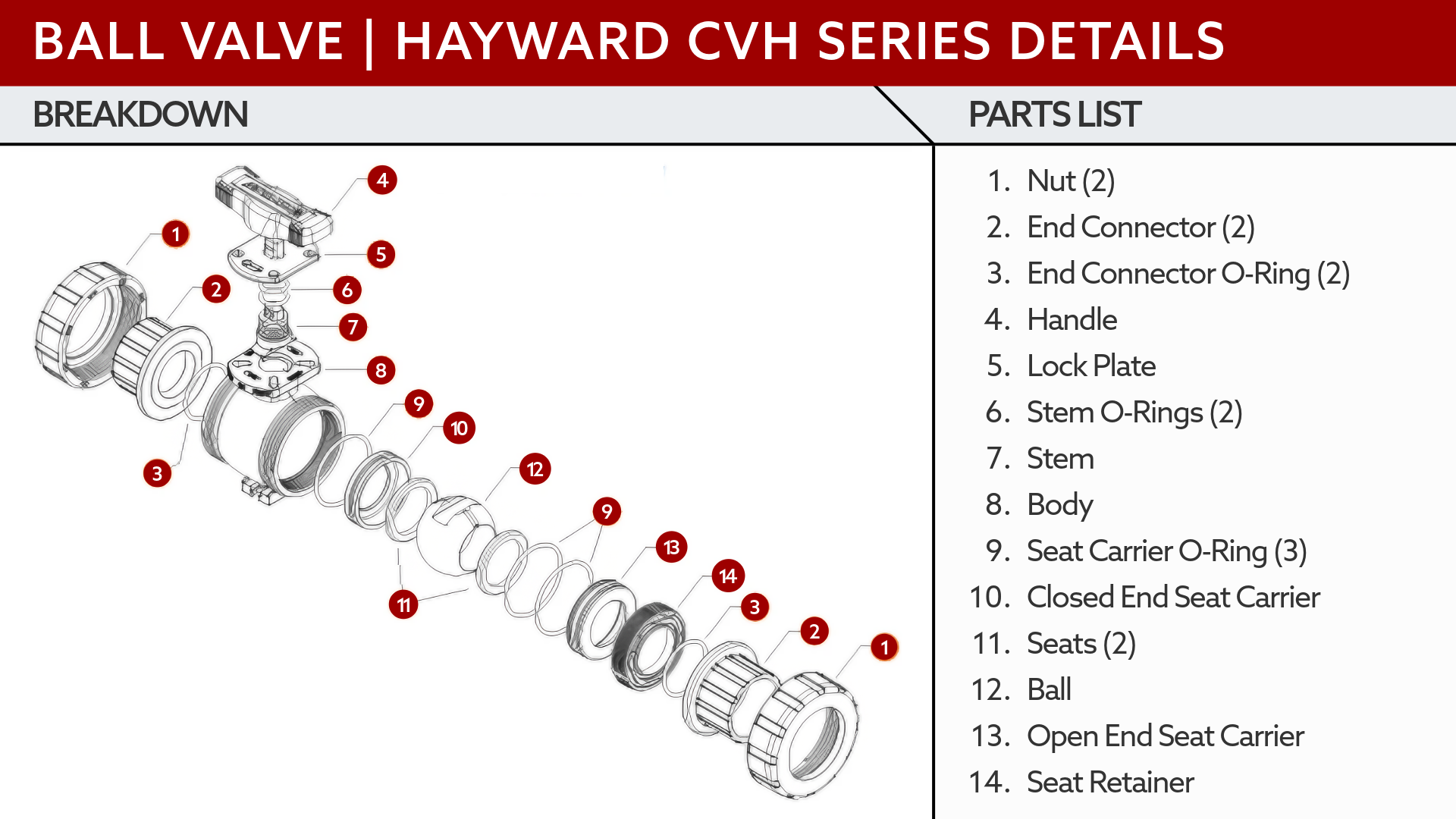

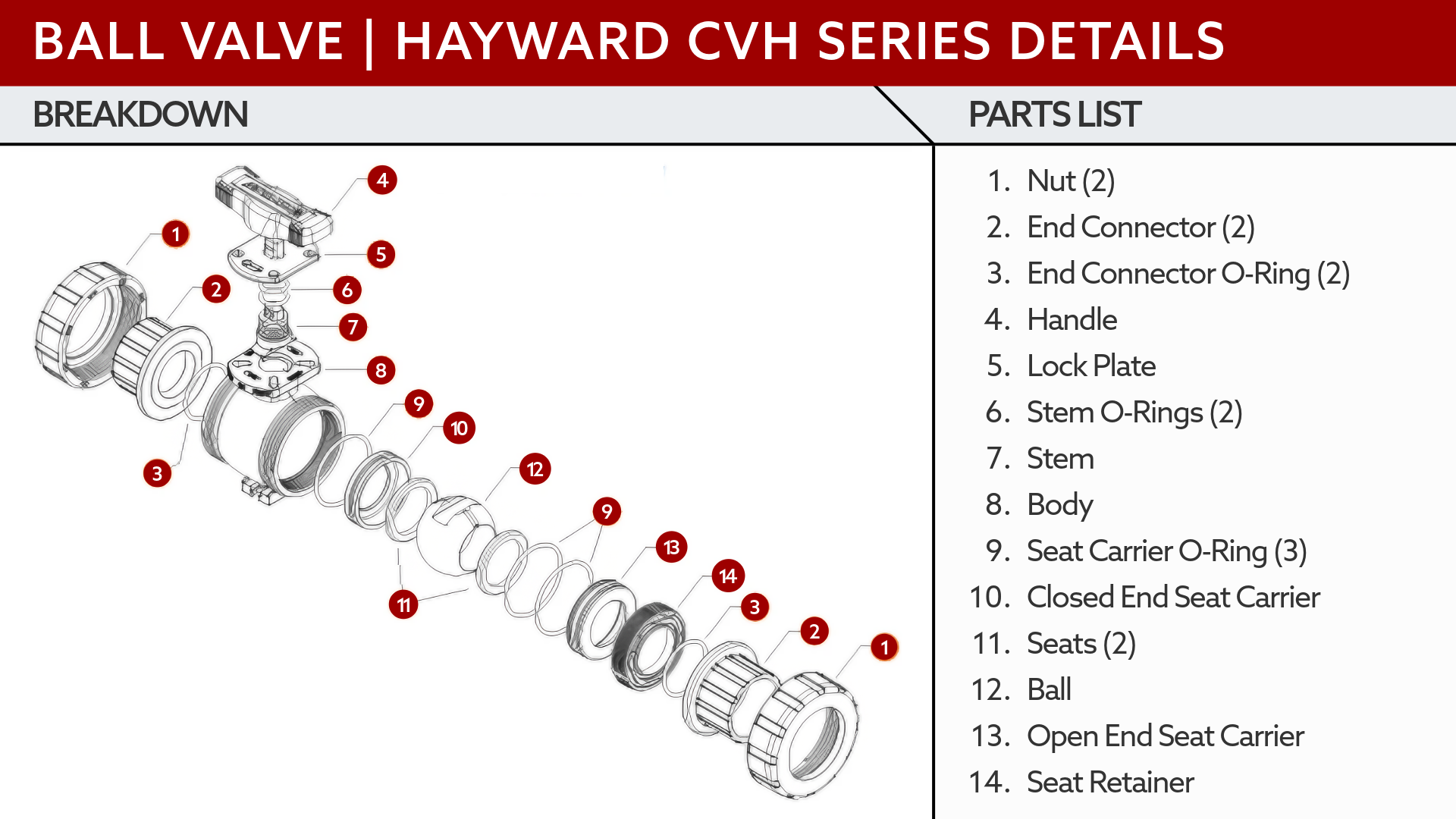

Ball valves are quarter turn rotary valves that use a hollow, perforated ball inside the valve body to control fluid flow. Here’s how they work:

- 1. Fluid enters the valve and approaches the ball.

- 2. A stem connects the ball to the handle for precise, easy control.

- 3. When the ball is rotated 90 degrees, its hollow port aligns with the flow path and allows fluid to pass through.

- 4. When the ball is rotated back, it blocks the path and stops flow with its solid side and creates a tight seal.

Key Features

Ball valves stand out for their:

- Bubble-tight Seal: Prevents leakage, even under high pressure.

- High Pressure Capability: Many can handle over 1,000 PSI (depending on type and construction material).

- Rapid Shutoff: Quarter turn operation allows quick response during an emergency.

- Unobstructed Flow: Full port designs accept fluid flow and eliminate restrictions.

- Manual or Automatic: Come in manually operated or actuator ready ball valves compatible with pneumatic or electric actuators for automated systems.

Applications

Common ball valve applications include:

- Oil & Gas: Flow control for pipelines, processing, and refining—handles high pressures and corrosive media.

- Food & Beverage: Food grade models ensure hygiene and control for ingredients, dairy, brewing, and beverage production.

- Residential Plumbing: Shutoff valves for water lines, irrigation, and appliance hookups—provides clear, reliable operation for homeowners.

- Manufacturing: Cooling water, hydraulic fluids, and non-pressurized air systems rely on ball valves for durability and minimal maintenance.

Advantages

- Exceptional Durability: Ball valves feature a simple construction with few moving parts, which results in excellent wear resistance and lasting seal integrity even after thousands of cycles.

- Versatility: Their design and range of material options allow effective handling of many liquid types—accommodating water, chemicals, mixtures, ingredients, and more. Multi-port 3 way ball valves can direct flow between several connections for complex systems.

- Minimal Pressure Drop: Full port ball valves offer an unobstructed flow path. When fully open, the bore aligns with the pipeline and maintains maximum flow rates. This is valuable wherever system pressure must be preserved.

Limitations

- Weight of Large Sizes: As the valve size increases, the solid ball and solid construction of the body add considerable weight. This can require additional piping support and may complicate installation in systems with larger diameter pipes.

- Higher Cost for Large Diameters: Large diameter ball valves need more machinery and material, which can make them more expensive compared to other valve types. For pipes above 6 inches, alternative valves often offer lower costs.

- Limited Flow Control: Ball valves are less suitable for precise throttling or graduated flow control. Their rapid open/close action makes it challenging to fine tune flow rates in applications that need exact adjustments.

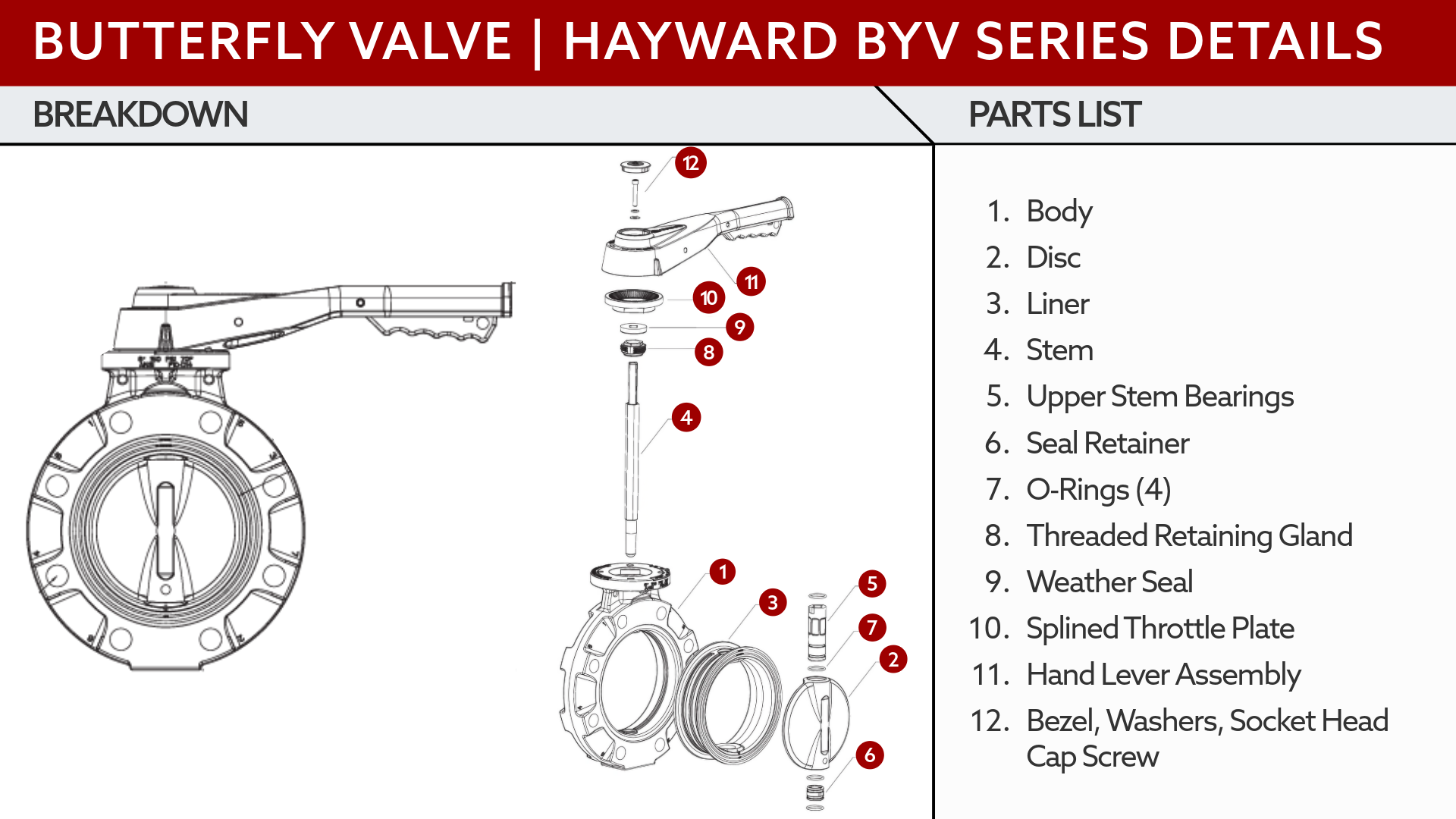

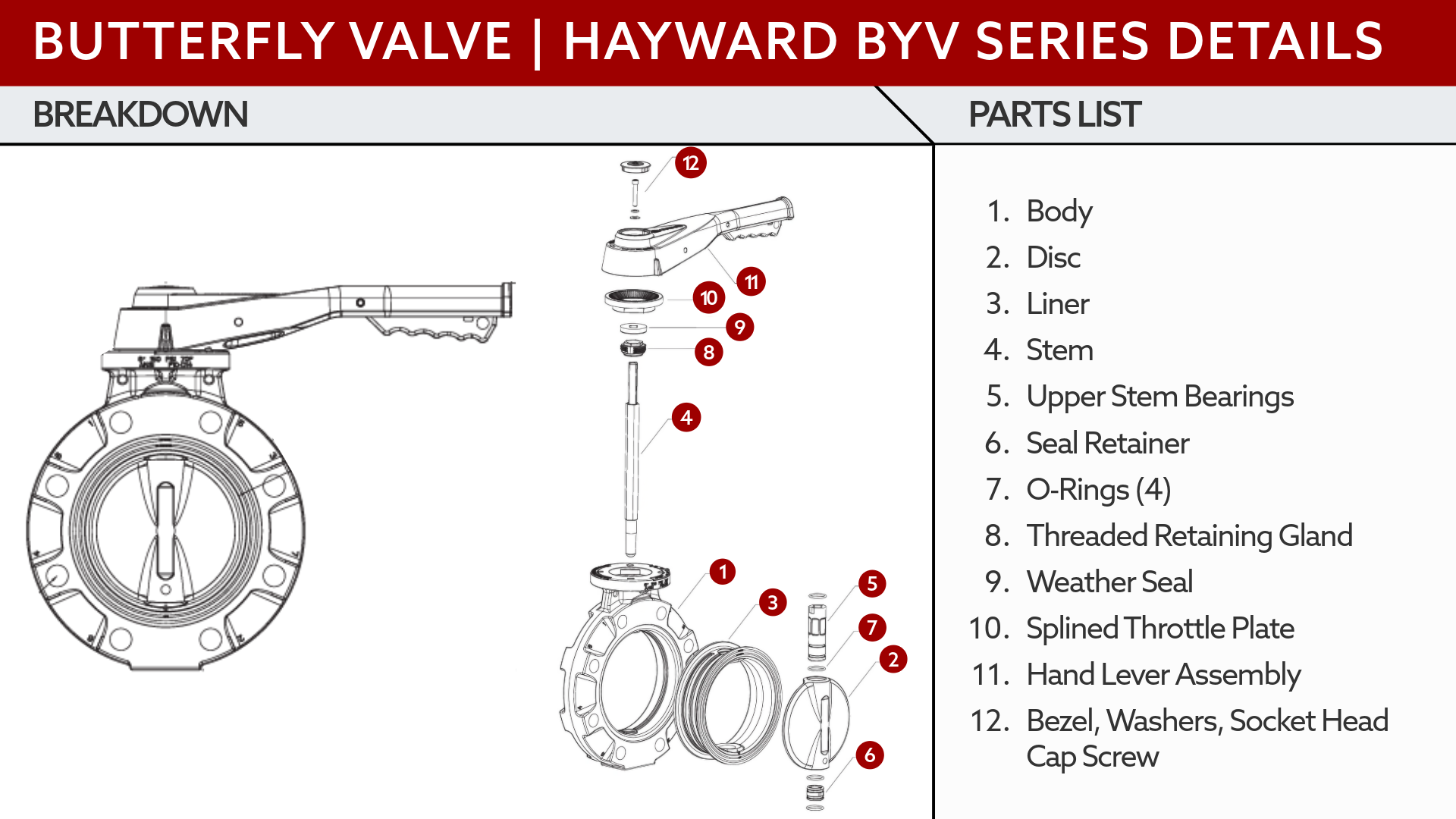

What Are Butterfly Valves?

Definition and Mechanism

Butterfly valves are quarter turn rotary valves designed to regulate fluid flow using a disc mounted on a central shaft inside the valve body. Here’s how they work:

- 1. Fluid enters the valve body, where it encounters a flat, circular disc positioned in the flow path.

- 2. When the valve handle, gear, or actuator is turned, the disc rotates on its central axis. Most feature a locking grasp lever on the handle for a simple grasp and turn operation.

- 3. As the disc rotates 90 degrees, it aligns parallel with the flow and creates an open pathway for fluid to pass through freely.

- 4. Most butterfly valves feature set angle locking positions for throttling flow rates.

- 5. Turning the disc back to its original position perpendicular with the pipeline blocks the flow entirely, effectively stopping it.

This straightforward mechanism allows for fast operation, providing quick transition between open and closed positions essential for efficient processes and emergency shutoff.

Key Features

Butterfly valves offer several features that make them particularly valuable for control in many fluid conveyance systems:

- Lightweight Construction: The thin body and disc design significantly reduces the valve’s overall weight, which is especially important for larger pipe diameters where heavier valves could require additional support.

- Cost Effective at Large Sizes: Compared to other valve types, butterfly valves become a more economical option as pipe size grows, making them suitable for projects on a budget or installations with large diameters.

- Compact Profile: Their slim body and minimal space requirements between flanges allow for easy installation in tight or crowded piping systems as well as retrofits.

- Fast Operation: The quarter turn movement provides quick opening and closing that is ideal for applications that demand frequent cycling or immediate shutoff.

- Locking Positions: Professional quality butterfly valves have set angle locking positions, sometimes up to every 5 degrees, to allow direct control over liquid flow rates through the valve.

- Full Range Flow Control: Geared butterfly valves replace the lever with a spigot style handle that turns like a dial and uses a gearbox mechanism for faster, easier operation and precise flow control.

- Manual or Automatic: Butterfly valves can be operated manually or fitted with pneumatic or electric actuators for automated systems with actuator ready butterfly valves.

Applications

Butterfly valves are deployed in a wide range of applications that benefit from their combination of size, cost, and ease of use:

- Municipal Water Systems: In distribution networks and treatment plants, butterfly valves are used to control the flow of large water volumes in main lines and pumping stations.

- Wastewater Treatment Facilities: Butterfly valves are often used in raw sewage intake, clarifiers, and discharge lines due to their ability to handle high volumes, resist buildup, and be disassembled for cleaning.

- Agricultural Irrigation: Frequently found in irrigation channels, pump setups, and mainline controls, butterfly valves provide reliable management of liquid delivery while keeping installation costs manageable.

- Additional Uses: Beyond these applications, butterfly valves are commonly used in chemical processing, HVAC systems, and fire protection—anywhere that demands large diameter, modular, and/or reliable flow control.

Advantages

- Cost Friendly Solution: Butterfly valves cost less than ball valves, particularly for larger sizes, making them more cost effective for large scale projects.

- Lightweight Design: Reduced weight minimizes structural support requirements and handling difficulties, making for easier installation procedures.

- Compact Installation: Minimal space requirements between pipe flanges allow for their use in confined spaces.

- Easy Cleaning: Smooth surfaces and a simple design promote thorough cleaning, ideal for sanitary applications and those where buildup is expected.

- Quick Operation: Quarter turn lever mechanism provides rapid valve changes for frequent operations or emergency scenarios.

- Low Maintenance: Few moving parts result in less maintenance, longer service intervals, and fewer disruptions.

Limitations

- Pressure Drop: The disc remains in the flow path even when open, which creates turbulence and reduces system pressure.

- High Pressure Sealing: Sealing reliability decreases as system pressure increases, increasing the potential for leakage issues.

- Material Compatibility: Butterfly valves are designed for non-compressible liquids and should not be used with compressible fluids like air or gases.

- Flow Velocity: Exceeding the valve’s recommended maximum fluid velocity can lead to damage from water hammer effects.

- Operating Difficulty: High upstream pressure can make valve operation challenging, sometimes requiring bypass systems to facilitate shutoffs.

- No Pigging Capability: The obstruction caused by the central disc prevents pipeline cleaning operations using pigs or other such pipe cleaning devices.

Key Differences Between Ball Valves and Butterfly Valves

While ball valves and butterfly valves share the convenience of quarter turn operation, their fundamental design differences create distinct performance characteristics that make each better suited for specific applications. Understanding these differences is essential to select the right valve type for your system's operating requirements, budget, and performance demands.

The table below provides a side by side comparison of the differences between ball valves and butterfly valves:

| Feature | Ball Valve | Butterfly Valve |

| Weight | Heavier, especially at larger diameters; may require support | Lighter relative weight, especially at larger diameters |

| Size | Better suited for smaller pipe sizes (below DN 50, or 2") | Suitable for larger pipe sizes (above DN 150, or 6") due to lighter weight |

| Flow Control | Suitable for ON/OFF control. Not recommended for flow control (throttle) applications | Suitable for ON/OFF control. Preset locking angles; excellent for flow control (throttle) applications |

| Flow Regulation | Can be used for on/off control and proportional control when using a V-port ball; better relative flow regulation than butterfly valves | Can be used for on/off control and proportional control |

| Flow Restriction | Full port ball valves; no pressure drop | Disc restricts flow, creating turbulence and pressure drop |

| Installation Space | Larger footprint; requires more installation space | Smaller footprint; requires less installation space |

| Seal | Provides a tight seal in plumbing applications that require zero leak-through when shut off | More potential for leakage at higher pressures |

| Connection Style | Wide selection of connection types with threads, unions, or sockets | Most have flanged connections; NPT and tri-clamp styles sometimes available |

| Operating Conditions | Suitable for high pressure applications (many models support up to 1000 PSI); certain seal materials tolerate even higher pressure | Typically operates at a lower maximum pressure range |

| Port | Available in 3 way (T or L) port designs | Two port options only |

These differences highlight why selecting the right pipe valve is never a one-size-fits-all decision. Ball valves excel in high-pressure, smaller diameter applications where tight seals are critical, while butterfly valves excel in flow regulation and larger diameter systems where some pressure drop is acceptable.

The choice between ball and butterfly valves ultimately depends on your specific pipeline needs such as pipe size, operating pressure, budget considerations, throttling requirements, and maintenance preferences. Consider these specifics to ensure you achieve optimal performance and long term reliability in your plumbing system.

How to Choose the Right Valve

Selecting between ball valves and butterfly valves requires a careful evaluation of your system's specific requirements, and the right choice will optimize operational activities, functionality, and minimize maintenance headaches.

System Requirements

Operating Pressure

- Choose ball valves for high pressure applications (above 150 PSI) where tight sealing is critical.

- Select butterfly valves for low to moderate pressure systems where rate control and pricing outweigh sealing precision.

- Ball valves handle extreme temperatures better, making them ideal for steam, hot oil, or cryogenic applications

- Butterfly valves work well in standard temperature ranges typical of water and wastewater systems

Flow Control Needs

- Use ball valves when you need complete shutoff with zero leakage tolerance.

- Choose butterfly valves for applications requiring flow rate throttling and where some flow turbulence is acceptable.

- Both valves work for full on/off control, but ball valves provide superior sealing reliability in higher liquid pressure pipelines.

Pipe Size Guidelines

- Small to Medium Diameters (2" and smaller): Ball valves excel in smaller pipe sizes due to their compact body design and superior sealing capabilities. The weight difference is negligible at these sizes.

- Large Diameters (6" and larger): Butterfly valves are the ideal choice for large pipe systems. A 12" butterfly valve can cost 60-70% less than an equivalent ball valve and weigh significantly less, reducing installation complexity and structural support requirements.

Maintenance Requirements

Cleaning and Sanitation

- Butterfly valves offer easier cleaning with smooth surfaces and their simple disc design.

- Ball valves may trap debris in the ball cavity, requiring more thorough maintenance procedures.

- Food, beverage, and pharmaceutical applications often favor butterfly valves for sanitary reasons.

Budget Considerations

Initial Investment vs. Lifecycle Costs

- Depending on size, ball valves may cost more upfront but offer minimal operating concerns.

- Butterfly valves provide immediate savings for large diameter piping applications.

- Both valve types offer similar service lives when used correctly under similar conditions.

Project Scale Impact

For large infrastructure projects with dozens of valves, the savings from butterfly valves can be substantial. For critical process applications with few valves, the reliability of ball valves often makes them the best option and justifies potentially higher costs.

Real World Application Examples

Choose Ball Valves When:

- Installing shutoff valves in residential plumbing systems.

- Controlling high pressure fluid lines.

- Managing chemical processes with zero leakage shutoff requirements.

- Working with systems under 6" diameter that don’t require flow rate modulation.

Choose Butterfly Valves When:

- Managing municipal water distribution networks.

- Controlling flow in wastewater treatment plants, chemical processing, and manufacturing lines.

- Installing valves in large diameter HVAC systems

- Budget constraints are the primary consideration for large pipe systems.

TakeawayThe choice between ball valves and butterfly valves ultimately depends on balancing performance requirements with practical constraints. Ball valves deliver superior sealing and high pressure capability, making them well suited overall for many applications. Butterfly valves provide a cost effective solution for large diameter plumbing where mild pressure drop and turbulence are acceptable. The takeaway: consider your system's pressure requirements, pipe sizes, maintenance capabilities, flow rate control needs, and budget range together to make the best decision that optimizes both performance and value. |

|

Takeaway

The choice between ball valves and butterfly valves ultimately depends on balancing performance requirements with practical constraints. Ball valves deliver superior sealing and high pressure capability, making them well suited overall for many applications. Butterfly valves provide a cost effective solution for large diameter plumbing where mild pressure drop and turbulence are acceptable.

The takeaway: consider your system's pressure requirements, pipe sizes, maintenance capabilities, flow rate control needs, and budget range together to make the best decision that optimizes both performance and value.

Expert Guidance for Your Valve Selection

Ready to find the perfect pipe valve for your project? PVC Pipe Supplies offers a full catalog of PVC and CPVC ball valves and butterfly valves in various models made by the industry’s leading manufacturers like Hayward, Georg Fischer, Spears, and Red Flag.

Need Expert Advice?

Our specialists understand that every application is unique. Contact PVC Pipe Supplies today to see how we can help you get a personalized recommendation based on your specific system requirements, budget, and performance goals—here to help you make the right choice the first time. Contact us to learn more about our special contractor discounts for bulk orders or get a quote when bidding for a job.