|

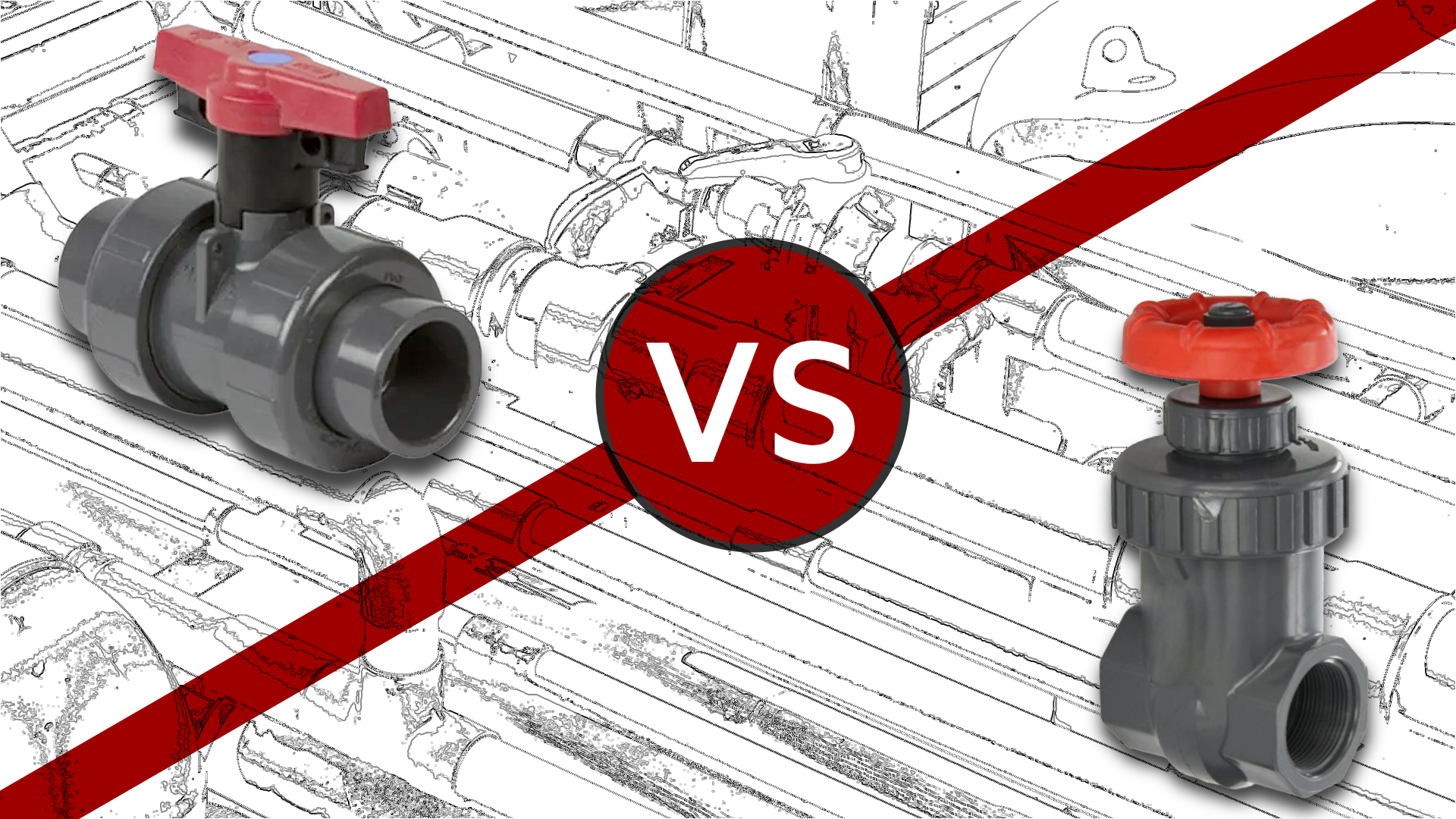

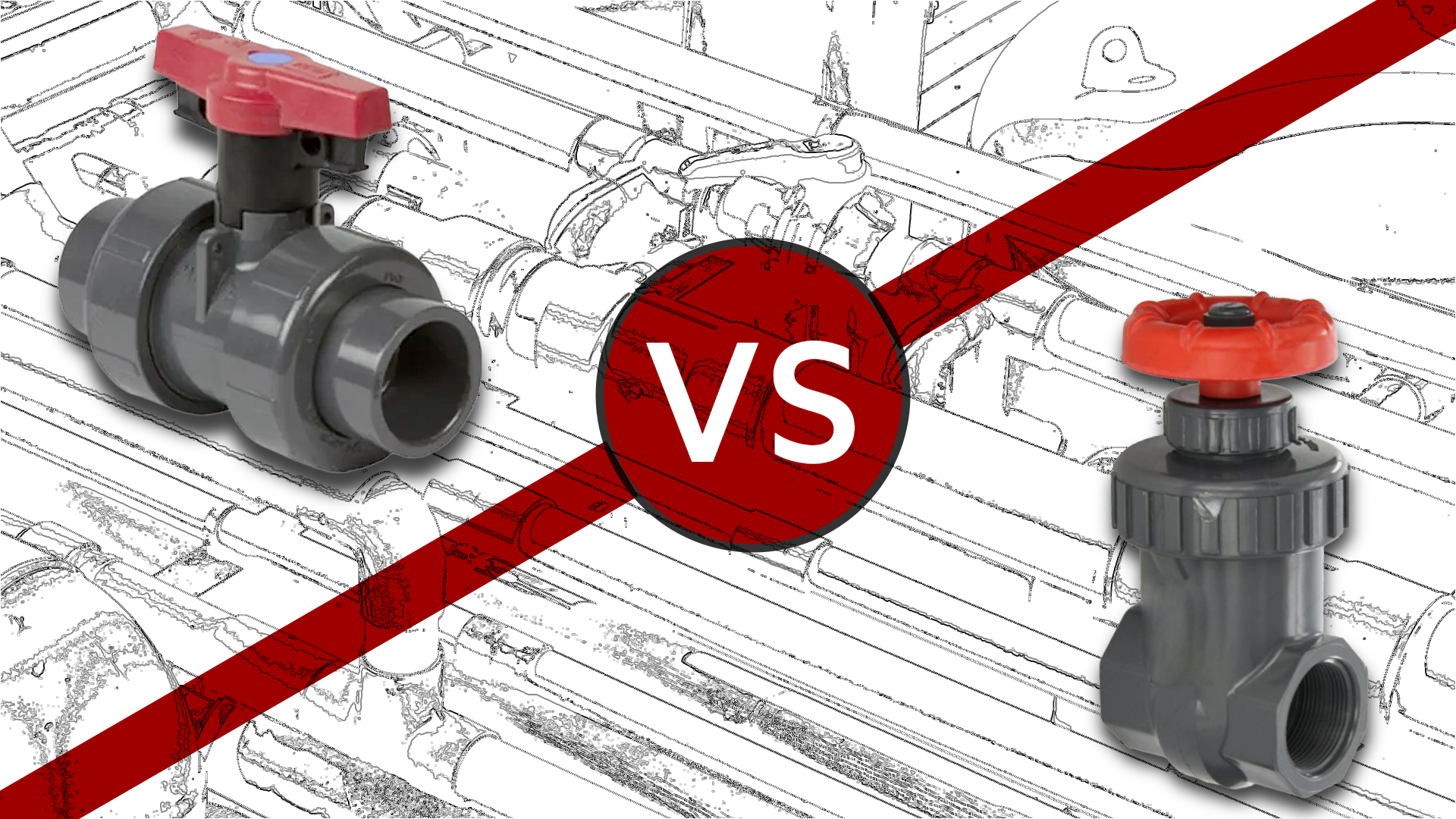

In liquid plumbing systems, it’s always important to select the right valve to ensure operations stay efficient and reliable. Ball valves and gate valves are ranked among the most common components for flow control. While both are used to start and stop the flow of liquids, they differ in their internal mechanisms, operating characteristics, and ideal applications. Understanding the differences will help you choose the most effective and durable valve for your specific application. This guide provides a detailed comparison of ball valves and gate valves and explores their designs, functions, and best use cases. |

In liquid plumbing systems, it’s always important to select the right valve to ensure operations stay efficient and reliable. Ball valves and gate valves are ranked among the most common components for flow control. While both are used to start and stop the flow of liquids, they differ in their internal mechanisms, operating characteristics, and ideal applications. Understanding the differences will help you choose the most effective and durable valve for your specific application. This guide provides a detailed comparison of ball valves and gate valves and explores their designs, functions, and best use cases.

What Are Ball Valves?

Ball valves are plumbing control devices used to turn liquid flow on or off. They are used in a wide range of systems—from residential plumbing to industrial process lines. Ball valves are known for their reliability, fast operation, and tight sealing in both low and high pressure scenarios.

Definition and Basic Function

A ball valve is a rotational, quarter turn valve that uses a hollow, perforated ball to control flow. Turning the handle 90 degrees rotates the ball inside the valve body. When the ball’s hole is aligned with the pipe, fluid passes through freely. When turned so the hole is perpendicular, the solid side of the ball blocks the flow to provide a secure, leak proof shutoff.

Key Components and Design

- Valve Body: The durable outer casing that connects the valve to the piping system.

- Ball: The main flow control element, with a precision drilled hole for media pass through.

- Stem: Links the handle to the ball and transmits rotational force.

- Seats: Rings—usually made of PTFE or other polymers—that create a tight seal between the ball and valve body when closed.

- Handle: Used for valve operation and offers a clear visual indicator of position; parallel to the pipe means open, perpendicular means closed.

- Pipeline Connection: Available in socket and threaded models with single union and true union designs.

Most ball valves are also easy to operate manually due to the handle. Automated ball valves are common in industrial applications where remote or frequent actuation is needed.

How Ball Valves Operate

Ball valves require only a quarter turn (90 degrees) to go from fully open to fully closed, making operation quick and straightforward. This rapid action makes them perfect for emergency shutoff or for systems that need to be frequently opened and closed.

When fully open, the unobstructed path through the ball results in minimal pressure drop to maintain near consistent flow. When closed, ball valves provide a bubble-tight seal, meaning not even bubbles can work their way through, effectively reducing leak risks. However, their fast acting mechanism means users should be mindful of water hammer in high pressure systems.

Practical Insights

Ball valves are ideal for applications where reliable shutoff, long life, and easy identification of current open/closed status are priorities. They’re commonly used in water lines, chemical handling, raw material pipelines, and any use case where downtime and maintenance need to be kept to a minimum.

With options for different sizes, materials (like brass, stainless steel, PVC, CPVC, and PVDF), and configurations (including multi-port designs), ball valves are a common go-to solution due to their adaptability to match a variety of commercial, industrial, and municipal needs.

What Are Gate Valves?

A gate valve is a linear control valve that manages fluid flow by raising or lowering a gate-like barrier across the flow path. These pipe valves have been a cornerstone of industrial, residential, and municipal water systems for decades, offering reliable shut off capabilities in high pressure applications and often used in small to medium sized pipelines.

Definition and Basic Function

Gate valves use a linear valve mechanism where a sliding gate moves perpendicular to the flow direction. The gate or wedge acts as a barrier that can be lifted completely out of the flow path for full flow or lowered to block flow.

Unlike rotary valves, gate valves provide a straight-through flow path when fully open that minimizes any pressure drop or turbulence. This makes them ideal for applications that require or benefit from unrestricted flow.

Key Components and Design

Gate valves feature five primary components:

- Valve body: Houses the internal mechanism and connects to the pipeline.

- Gate element: The sliding disc or wedge that controls flow.

- Stem: Connects the gate to the operating mechanism.

- Handwheel: The turn dial operating mechanism for opening and closing the valve.

- Bonnet: The top assembly that houses the stem and provides maintenance access.

- Pipeline Connection: Available in socket and threaded style connections

The handwheel operation system is the most recognizable feature of gate valves. This manual actuator requires multiple rotations to move the gate between open and closed positions. The threaded stem design provides a mechanical advantage as it allows operators to control high pressure systems with mild effort.

How Gate Valves Operate

Gate valves require multi turn operation, typically requiring 360+ degrees of rotation to move from fully closed to fully open. The handwheel turns the stem, which raises or lowers the gate, transferring the rotational force through a threaded mechanism.

The raising and lowering gate mechanism works as follows:

- Opening: Turning the handwheel counterclockwise lifts the gate out of the flow path.

- Closing: Clockwise rotation lowers the gate until it seats against the valve body, blocking flow.

This multi turn design provides precise control over gate positioning but requires more time and effort compared to quarter turn valves. The gradual operation helps prevent water hammer in high liquid pressure systems and makes gate valves particularly suitable for municipal water lines, residential and agricultural irrigation, and industrial applications.

Ball Valves vs Gate Valves: Direct Comparison

Choosing between ball valves and gate valves requires an understanding of their fundamental differences in operation, performance, and cost. Here, we’ll compare the key factors that influence which valve to select for specific applications.

Operation and Speed

Ball valves excel in applications requiring rapid response, offering quick shut off capabilities with just a 90 degree turn. This quarter turn operation makes ball valves ideal for emergency situations where immediate flow control is critical.

Gate valves provide slow, gradual operation, requiring multiple turns (360+ degrees) to move from open to closed. While this takes more time, the gradual movement of gate valves offers precise control and reduces system shock.

Water hammer considerations favor gate valves in high pressure plumbing systems. Ball valves' instant closure can create pressure surges that may damage pipes, while gate valves' gradual operation minimizes this risk.

Sealing and Leakage Performance

Ball valves deliver superior sealing performance with air tight shut off capabilities. Their design creates a reliable seal between the ball and seats, making them excellent choices for precision applications and isolation needs.

Gate valves face potential leakage issues due to their sliding gate mechanism. Over time, the gate and seat surfaces can wear, which can lead to internal leakage that requires maintenance or replacement.

Long term durability and maintenance favor ball valves. They typically require minimal maintenance and last longer in service, while gate valves may need more frequent inspection and replacement due to wear prone components.

Cost Analysis

Initial purchase costs vary on size. Costs for each valve are fairly similar up to 2 to 3 inches. For larger pipe sizes, budgets generally favor ball valves as they are typically less expensive than gate valves as connection size increases. This makes ball valves a better choice for projects with large quantities of valves on a budget.

Long term maintenance expenses lean the advantage toward ball valves. Their low maintenance needs and generally longer service life reduce ongoing costs, while gate valves typically require regular maintenance and earlier replacement.

Total cost of ownership often favors ball valves. The combination of longer life, reduced maintenance, and superior reliability makes them more economical over the system's lifetime.

Applications and Use Cases

Understanding where ball valves and gate valves perform best can help ensure optimal system performance and longevity. Each valve type excels in specific plumbing environments based on its unique operating characteristics and design strengths.

Ball Valve Applications

Oil and gas industry operations rely heavily on ball valves for their reliable sealing capabilities and quick shutoff features. These valves handle everything from wellhead control to pipeline isolation, where leak tight performance is critical for safety and environmental protection.

Food and beverage processing facilities choose ball valves for their sanitary design and easy cleaning capabilities. The smooth ball surface and minimal crevices prevent bacterial growth, while their quick operation supports production cycles and clean-in-place procedures.

Chemical handling and processing applications benefit from ball valves' excellent chemical resistance and air tight sealing. Their ability to handle corrosive fluids safely and minimal maintenance requirements makes them ideal for harsh chemical environments.

HVAC and plumbing systems commonly use ball valves for their durability and ease of operation. From residential water lines to commercial building systems, ball valves provide reliable service over decades of use.

High frequency operation scenarios strongly favor ball valves due to their quarter turn design and robust construction. Applications that require frequent cycling, including automated control systems and process equipment, benefit from the ability of ball valves to handle thousands of operations without failure.

Gate Valve Applications

Large water supply lines commonly use gate valves for their minimal flow restriction characteristics and ability to handle high volumes. Municipal water distribution systems rely on gate valves' straight through flow path that minimizes pressure loss, especially for large diameter pipelines.

Power plants and utilities depend on gate valves for their high pressure capabilities and reliability for critical, sensitive systems. These valves control steam, cooling water, and fuel lines, where gradual operation prevents system shock and maintains stability.

Mining operations employ gate valves for handling abrasive slurries and high pressure systems. Their robust construction and ability to provide full bore flow make them suitable for demanding mining applications, including tailings lines and process water systems.

Wastewater treatment facilities employ gate valves for their ability to handle dirty water and debris without clogging. The straight through flow path reduces the risk of blockages, while their simple design helps make maintenance easier in challenging environments.

High pressure, infrequent operation systems benefit from gate valves' gradual operation and pressure handling capabilities. Applications such as main line isolation valves and emergency shutoff systems rely on gate valves' ability to operate reliably after long periods of inactivity.

Industry Specific Considerations

Municipal water systems must balance performance, cost, and maintenance requirements. Gate valves serve well in transmission mains with high flow capacity and infrequent operation, while ball valves excel in distribution systems with frequent operation and tight shutoff needs.

Industrial manufacturing facilities typically use both valve types strategically. Ball valves handle process control and frequent operation requirements, while gate valves manage bulk flow and isolation duties where their cost advantages and high flow capabilities provide value.

Commercial plumbing applications increasingly favor ball valves for their reliability and low maintenance needs. However, gate valves remain common in older systems and applications where budget constraints or space limitations influence valve selection.

Advantages and Disadvantages

Evaluating the pros and cons of ball valves and gate valves can help provide a clear framework for selecting the right pipe valve for your needs. This quick comparison highlights the key advantages and disadvantages of each valve type.

Ball Valve Advantages

- Fast Operation: The quarter turn design allows for immediate shut off, making them ideal for situations where emergency response may be necessary.

- Excellent Sealing: Ball valves provide an air tight seal for superior leak protection compared to gate valves.

- Durability and Longevity: With fewer moving parts and a simpler design, they have low maintenance requirements and, on average, have a longer service life.

- Multi Port Configurations: Available in 3 way designs for more complex flow control, such as diverting or mixing.

- Easy Visual Confirmation: The handle's position (parallel for open, perpendicular for closed) makes it simple to verify the valve status at a glance.

Ball Valve Disadvantages

- Higher Initial Cost: Ball valves typically have a higher purchase price than gate valves of a similar size and construction type.

- Potential for Water Hammer: The rapid closing speed can cause pressure surges in high velocity, high pressure systems that can potentially damage pipes and equipment.

- Limited Throttling Capabilities: They are not designed for throttling flow, as partial opening can cause seat erosion and premature valve failure.

- Space Requirements: The lever handle requires a full 90 degree clearance, which can be a constraint in tight installations.

Gate Valve Advantages

- Lower Upfront Costs: Gate valves are generally more economical, especially in larger sizes.

- Suitable for High Pressure and Large Pipes: Their design is well suited for high pressure applications and large diameter pipelines.

- Minimal Pressure Drop: When fully open, the gate is completely out of the flow path, creating almost no resistance or pressure loss.

- Gradual Flow Control: The slow, multi turn operation helps prevent water hammer by allowing for more gradual system adjustments.

Gate Valve Disadvantages

- Slow Operation Speed: The multi turn handwheel makes opening and closing the valve a slow process.

- Prone to Leakage and Wear: The sliding gate and seat surfaces can wear over time, increasing the likelihood of leaks.

- Higher Maintenance Requirements: These valves often require more inspection and maintenance to ensure that they continue to provide proper sealing.

- Difficult to Determine Status: Without a position indicator, it can be difficult to visually confirm if the valve is fully open or closed.

How to Choose Between Ball Valves and Gate Valves

Choosing the right valve comes down to your specific application needs, operating environment, and budget. This systematic approach will help achieve optimal performance and cost effectiveness over the service life of your valves and plumbing system.

Application Requirements

- Flow Rate & Pressure: Ball valves are best for quick shut off in moderate to high flow, low to moderate pressure systems. Gate valves suit high pressure, high volume lines.

- Frequency of Use: Ball valves work well for frequent cycling. Gate valves are ideal for infrequent operation.

- Emergency Shut Off: For fast response, ball valves are preferable due to their quarter turn action.

Environmental Factors

- Temperature & Pressure Tolerance: Match valve type and material to your system’s temperature and pressure range. Ball valves traditionally have more construction material options than gate valves.

- Fluid Compatibility: Choose materials (valve body, seats, and seals) that are compatible with your fluid, especially for corrosive media.

Physical Constraints

- Pipe Size: Ball valves generally have a wider selection of sizes; gate valves are better for large diameters.

- Space: Ball valves need handle clearance; gate valves need space above for the handwheel.

- Access: Ball valves' clear open/closed position and low upkeep suit hard-to-reach spots.

Budget

- Upfront Cost: Ball valves usually cost less initially.

- Maintenance: Ball valves save on maintenance and replacements over time, often reducing the total cost of ownership.

- Life Cycle Value: Consider all costs—purchase, upkeep, and longevity—for the best investment.

Material Options and Specifications

Choosing the right valve material, size, and features plays a role in long lasting, reliable performance.

Common Valve Materials

- PVC & CPVC: Great for general chemical resistance—PVC is ideal for cool liquids, while CPVC handles higher temperatures.

- Brass & Bronze: Durable and corrosion-resistant, these work well in standard plumbing, marine, and aggressive water conditions.

- Stainless Steel: Best for corrosive or high temperature environments—used in food, chemical, and pharmaceutical systems.

- PVDF: High purity, premium grade material offering excellent chemical resistance, temperature tolerance, and sanitation.

Size and Pressure Options

- Ball Valves: Common sizes range from 1/2” up to 8”; large diameter ball valves are available on request.

Gate - Valves: Common sizes range from 1/2” up to 4”.

- Residential Valves: 1/2" to 2" for home plumbing and irrigation.

- Commercial & Industrial Valves: 2" to 12"+ for high flow systems.

- Pressure Ratings: Most PVC and CPVC pipe valves handle up to 150–250 PSI.

Special Features

- Manual or Automated Control: Options include handwheels or levers (manual) or electric, pneumatic, and hydraulic actuators (actuated valves).

- Multi Port Configurations: Ball valves are available in 3 way designs for complex flow control and simplifying piping layouts.

Installation and Maintenance Best Practices

Proper installation and maintenance will keep your valves performing safely and efficiently. Here are the essential tips:

Installation Guidelines

- Orientation: Ball valves work in any position; gate valves perform best vertically with the stem upright.

- Support & Alignment: Provide support for large valves and align pipes to avoid stress and leaks.

- Testing: Pressure test at working pressure and check for seamless valve operation before use.

Maintenance Tips

- Inspections: Ball valves generally need annual checks; gate valves benefit from more frequent inspections.

- Prevention: Operate valves occasionally to prevent sticking.

- Wear Signs: Replace or repair if there’s leakage, hard operation, or noise during use.

Safety Essentials

- Lockout/Tagout: Always lock and tag valves before maintenance.

- Depressurize: Relieve system pressure before servicing or removing valves.

- PPE: Use gloves, safety glasses, and any job specific protective gear.

The Right Valve for Your Application from PVC Pipe Supplies

Ball valves and gate valves are fundamental parts of liquid plumbing systems, and each offers distinct advantages for specific applications. From the rapid, reliable shutoff of ball valves for a chemical processing line to the gradual, pressure control of a gate valve in a water pipe, selecting the right valve is essential for performance, safety, and service life.

PVC Pipe Supplies offers an extensive selection of high quality ball and gate valves in various sizes, types, and construction materials to meet the unique, rigorous demands of individual commercial, industrial, and residential applications. Our inventory features durable materials like PVC, CPVC, and PVDF (available on request), so you can find the valve with the right chemical resistance and specifications for your project.

Explore our full range of ball valves and gate valves to find the perfect fit for your needs. Visit our resource center for more information or contact PVC Pipe Supplies today for assistance in product selection.