PVC pipes, including white PVC and gray PVC, are the backbone of countless systems, from residential plumbing to large scale industrial and electrical projects. Durable, affordable, and versatile, they are a go-to material for professional contractors, design engineers, and DIYers alike. Understanding the differences between white and gray PVC pipes is necessary to select the right material for your project. Whether you’re wondering which PVC pipe to use for plumbing, the best PVC pipe for electrical conduit, or how to meet PVC pipe building code requirements, this guide will compare white pvc pipe vs gray pvc pipe to help both your decision and your project’s success.

White PVC Pipe

Primary Use:

- Ideal for plumbing systems, including water supply, drainage, and venting.

Key Characteristics:

- Durable: Resistant to corrosion for decades of performance under ideal conditions.

- Lightweight: Easy to handle and install, benefiting both professionals and DIY hobbyists.

- Smooth Interior: Promotes efficient water flow by minimizing friction and preventing blockages.

- Chemical Resistance: Withstands exposure to chemicals commonly found in plumbing systems.

- Size Versatility: Available in a wide range of sizes to meet various plumbing jobs.

Limitations:

- Lack of UV Resistance: Not suitable for prolonged outdoor exposure, as sunlight can cause degradation.

Gray PVC Pipe

Primary Uses:

- Electrical Conduit: Provides a protective pathway for electrical wires and cables.

- Schedule 80 PVC: Ideal for high pressure plumbing and industrial applications.

- Duct PVC: Designed for air handling and ventilation systems.

Key Characteristics:

Electrical Conduit:- UV resistant and suitable for prolonged outdoor exposure.

- Rigid structure offers stability and protection for electrical wiring.

- Durable and weather resistant, ideal for underground, indoor, and outdoor installations.

- Made with thicker walls for handling higher fluid pressures.

- Widely used in industrial and commercial settings due to its strength and reliability.

- Lightweight, lower cost, and easy to install compared to metal alternatives.

- Corrosion resistant, ideal for air handling systems and suitable for chemical fume handling.

Limitations:

Electrical Conduit:- Not pressure tested; unsuitable for plumbing applications.

- Heavier and more expensive compared to Schedule 40 PVC.

- Not designed to handle liquids or pressure applications; limited to ductwork systems.

Difference Between White and Gray PVC Pipes

Application:

- White PVC: Primarily used in plumbing systems for the supply, drainage, and venting of liquids and non-pressurized air or gaseous media (DWV applications).

- Gray PVC: Versatile, with options for electrical conduit, high pressure plumbing (Schedule 80), or for air handling and ventilation (duct PVC).

UV Resistance:

- White PVC: Often lacks UV resistance and unsuitable for prolonged outdoor use.

- Gray PVC: UV resistant due to stabilizing compounds, making it suitable for outdoor use.

Structure:

- White PVC: Rigid, with slight flexibility, and adaptable for plumbing configurations and various setups.

- Gray PVC: Rigid, providing beneficial stability for electrical wiring or industrial installations.

Color:

- White PVC: Bright white, commonly associated with residential and indoor plumbing.

- Gray PVC: Darker gray, distinguishing it for industrial, electrical, or specialized uses.

Pressure Testing:

- White PVC: Pressure tested and certified for plumbing applications.

- Gray PVC: Schedule 80 PVC is pressure rated for more demanding industrial and commercial applications. Electrical conduit and duct PVC are not pressure tested, restricting their use in high pressure scenarios.

White vs Gray PVC Comparison Table

The following table highlights the distinct differences between white PVC and gray PVC pipes across applications, UV resistance, structure, color, and pressure testing:

| Category | White PVC | Gray PVC |

| Application | Plumbing systems for water supply, drainage, and venting | Electrical conduit, high pressure plumbing (Schedule 80), or air handling (duct PVC) |

| UV Resistance | Typically lacks UV resistance | UV resistant |

| Structure | Rigid, with mild flexibility | Rigid |

| Color | Bright white | Darker gray |

| Pressure Testing | Pressure tested | Schedule 80 is pressure tested; electrical conduit and duct PVC are not pressure tested |

Follow Building and Plumbing Codes

Reference Standard Codes:

- Always check and follow recognized building and plumbing codes — such as the Uniform Building Code (UBC), International Building Code (IBC), and Uniform Plumbing Code (UPC) — when selecting and installing PVC pipes in applications where permits or inspections typically apply.

Choose the Right Pipe:

- Using the incorrect type (for example, conduit PVC for plumbing, or white PVC outdoors) can lead to leaks, material failure, or non compliance.

Risks of Improper Use:

- Safety hazards

- Project delays

- Possible fines

- Failed inspections, more work or complete project overhaul

Benefits of Compliance:

- Safe, reliable installations

- Protection of property and people

- Smooth project approvals and long term system integrity

Follow Local Codes

- Adhere to State and Local Requirements: In addition to national standards, always verify and comply with any state and local plumbing codes that apply, such as the California Plumbing Code (CPC) or New York City Plumbing Code, which may contain more specific requirements.

Why It Matters:

- Local codes can override or expand on national standards, so checking with your local building department or the authority with jurisdiction will ensure your project is up to code and avoid unexpected issues.

FAQ Section on White & Gray PVC Pipe

What is the difference between white PVC and gray PVC?

White and gray PVC pipes differ in their applications, formulations, and physical properties, which make them suitable for specific uses:

- White PVC is known for its clean, bright appearance and is commonly used in residential plumbing, water supply lines, and construction projects. It is lightweight, impact resistant, and may include UV resistant additives for outdoor use.

- Gray PVC has a more industrial look and is designed for electrical conduits, industrial or commercial chemical handling, as well as ventilation, drainage, and waste systems. It is typically more robust, with additives that improve strength and chemical resistance, making it ideal for harsher environments. Gray PVC is also UV protected and meets specific regulatory standards for electrical installations.

Which PVC pipe should I use for plumbing?

You should use white PVC for plumbing systems since it’s pressure tested and specifically designed for water supply, irrigation, and drainage applications, as in DWV pipe and fittings. Gray PVC, with the exception of Schedule 80 pipe, is not pressure rated and not suitable for regular plumbing use.

What is the best PVC pipe for electrical conduit?

Gray PVC is the best choice for electrical conduit. It is UV resistant, rigid, and provides excellent protection for wires and cables in both outdoor and underground installations.

Are there building codes for PVC pipes?

Yes, building codes like the UBC (Uniform Building Code), IBC (International Building Code), and plumbing codes such as the UPC (Uniform Plumbing Code) govern the use of PVC pipes. Always check local or state codes as they may have additional regulations or requirements.

Can I use white PVC outdoors?

White PVC doesn’t usually have stabilizing compounds to protect it so it can break down over time when exposed to sunlight. Gray PVC is better suited for outdoor applications due to added stabilizers that provide UV protection and adds to the pipe’s color.

Standardized, Compliant Pipe from PVC Pipe Supplies

Choosing the right PVC pipe — white or gray — is essential for the success, safety, and compliance of any piping project. Each type of PVC pipe serves specific applications. White PVC is often made for plumbing systems, while gray PVC is made in several types for either electrical conduit, high pressure plumbing, or ductwork and ventilation applications. Understanding the differences will ensure you select the correct material as well as avoid poor performance, safety risks, and regulatory issues.

For professional grade, compliant PVC pipe and fittings, shop at PVC Pipe Supplies — your certified PVC pipe supplier. Explore our wide selection of white and gray PVC pipes, fittings, and accessories to find the perfect solution for your project. Easily buy online and have your order shipped directly to your location, hassle-free.

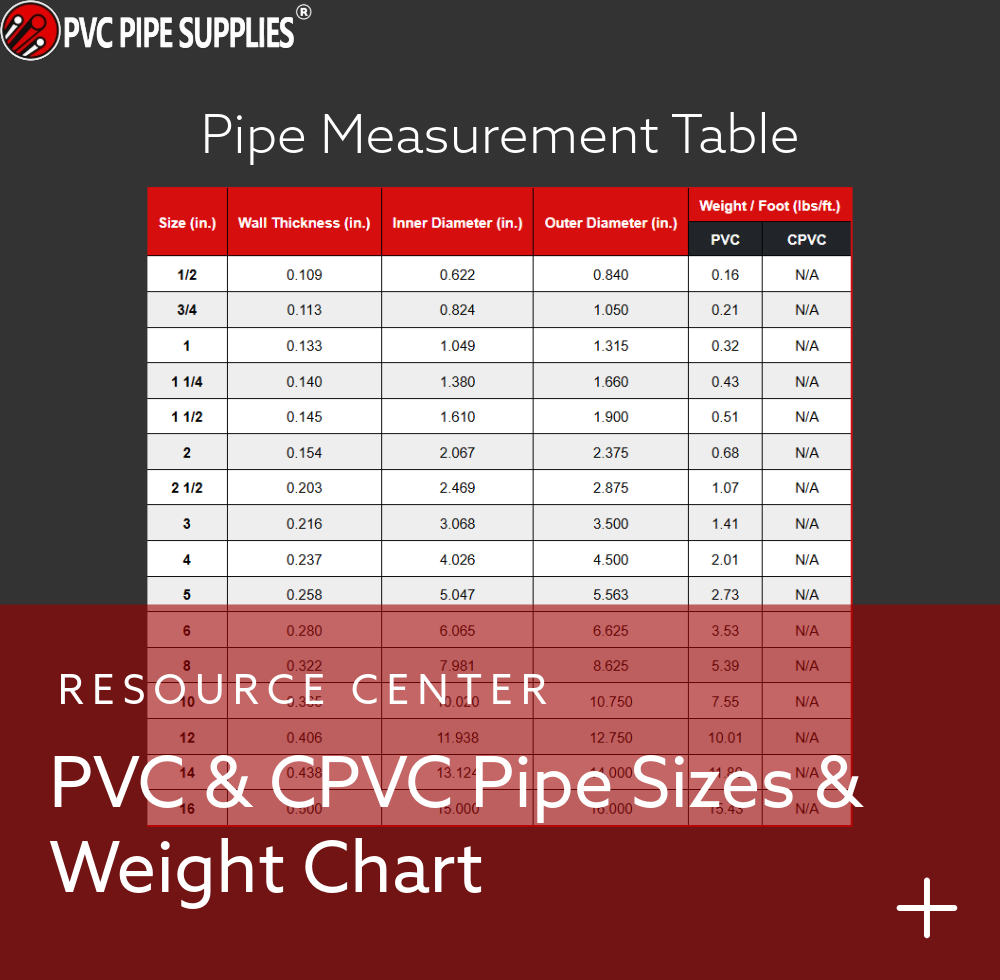

Need more information? Visit our Resource Center for guides on PVC pipe types, CPVC pipe, cement set times, sizing charts, and more.

Contractors: Contact us today to access exclusive bulk PVC pipe order discounts and streamline your next project.