Is PVC pipe a long term solution for your plumbing or construction needs? When selecting materials for building jobs, repair projects, or chemical conveyance systems, lasting durability is a high determining factor, and PVC pipes often stand out as an option for their affordability and versatility. But how long do they hold up under the pressures of daily use and exposure?

The lifespan of PVC pipe plays a large role in ensuring the cost effectiveness and reliability of plumbing, irrigation, drainage, and ductwork systems. Knowing how long these pipes last and what affects their strength can help you choose the right option for your project, whether you're a contractor managing large installations or a DIYer working on a home project.

This guide will look at what impacts how long PVC pipes last, explain how long different types of PVC pipes typically stay in good shape, share practical maintenance advice, and outline the warning signs that it might be time to replace them.

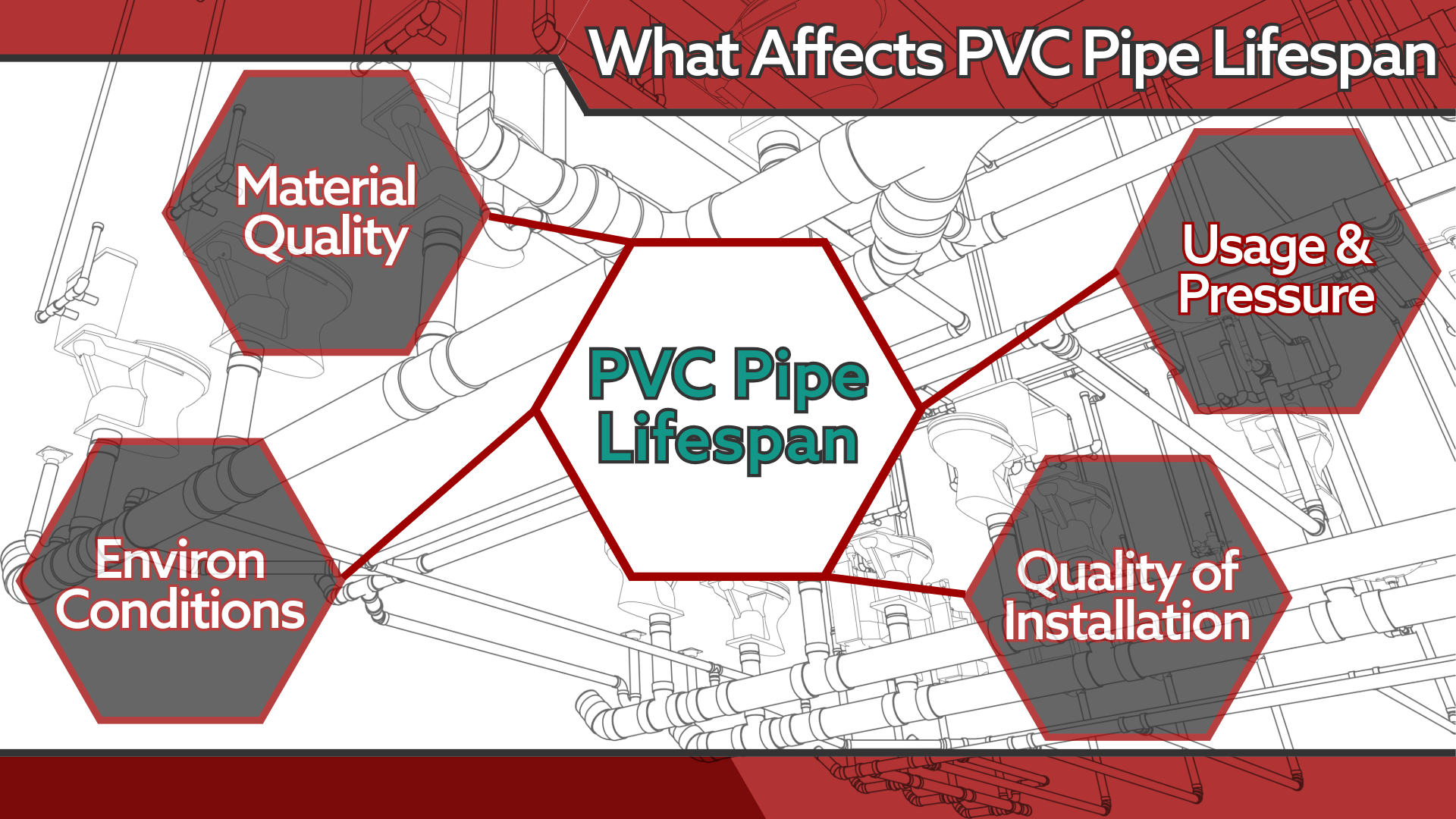

Factors Affecting the Lifespan of PVC Pipes

The lifespan of PVC pipes can vary significantly depending on several key factors. Understanding what impacts their durability can help ensure that your plumbing or construction projects remain functional and cost effective for years to come.

Material Quality

The quality of the PVC material used in your pipe system is a fundamental determinant of its longevity.

- High Grade PVC and Manufacturing Standards: Pipes made from high quality PVC adhere to strict manufacturing standards that are set in place to ensure consistent performance. Low grade PVC is more likely to develop cracks, sagging, discoloration, or even leach harmful materials over time, especially when exposed to challenging conditions. Always choose pipes certified by industry standards, such as ASTM, ANSI, and NSF, to guarantee you’re using a product designed for long term reliability.

- The Role of Additives in Durability: Additives like UV stabilizers and plasticizers can greatly improve the lifespan of PVC pipes. UV stabilizers, such as titanium dioxide and carbon black, protect pipes from prolonged exposure to sunlight, which works to prevent pipes from becoming brittle or losing their structural integrity. Plasticizers, on the other hand, provide flexibility and reduce the risk of cracking under stress. While plasticizers are not used in rigid uPVC pipes, they are in flexible PVC pipes. These enhancements make PVC piping systems suitable for a broader range of applications, from outdoor plumbing to industrial drainage systems.

Environmental Conditions

Where PVC pipes are installed and the environment they operate in can also determine how well they stand the test of time.

|

|

|

- Exposure to UV Rays: When PVC pipes are used outdoors, prolonged exposure to UV light can cause damage to the material. Without sufficient prevention, the pipe surface can lose its flexibility and eventually crack. To mitigate this, use UV stabilized pipes or add protective coatings for outdoor, above ground installations.

- Chemical and Temperature Exposure: PVC pipes exposed to aggressive chemicals or elevated liquid temperatures are more prone to wear and tear. For example, strong acids or alkaline solutions can corrode the interior of the pipe, especially for chemicals without full compatibility, while temperatures consistently near or exceeding the material’s limits (around 140°F for PVC, 200°F for CPVC) can cause warping or softening. Installing pipes with the correct chemical resistance or temperature rating can help prevent these issues.

- Indoor vs. Outdoor Applications: Indoor plumbing systems typically provide more favorable conditions for PVC pipes, with stable temperatures and minimal sunlight exposure. Outdoor systems will face more environmental challenges, such as fluctuating temperatures, UV rays, and mechanical stressors from exposure.

Usage and Pressure

How PVC pipes are used and the forces they endure during operation can also have a part in affecting their lifespan.

|

|

- Impact of Pressure: PVC pipes have specific liquid pressure ratings, and exceeding these limits can quickly lead to problems or complete system failure. High pressure water systems or industrial applications that require heavy duty performance should always adhere to the specified PSI limits per temperature guidelines to avoid premature failure.

- Type of Fluid Transported: The type of fluid transported through PVC pipes can also influence durability. While PVC can handle a variety of fluids, including water and many chemicals, certain highly reactive chemicals or solvents can cause slow to rapid degradation. Always confirm chemical compatibility before installation. We offer some guidance on PVC pipe chemical compatibility; when in doubt, verify with the pipe manufacturer.

Quality of Installation

Even professional grade PVC pipes can fail prematurely if not installed correctly. Proper installation plays an enormous role in pipeline service life.

- Alignment and Joint Sealing: Pipes that are poorly aligned or improperly joined will likely experience unnecessary stress, which can result in weak points that may lead to leaks or cracks. Correct alignment and the use of quality, manufacturer approved solvent cement for sealing joints significantly reduces these risks.

- Support and Load Management: Adequate support along the length of the pipe is essential to prevent sagging or bending, especially in above ground, suspended, and vertical installations. Load stress from bad weight distribution can place extra force at select spots that weaken the material and increase the chances of failure. Regular inspections to ensure supports remain intact and working properly can further extend the lifespan of a PVC pipe system.

From material quality to environmental exposure and installation practices, many factors contribute to how long PVC pipes will last. Understanding the variables and putting the best practices into action can ensure your piping systems remain viable and reliable for years to come.

Typical Lifespan of Different Types of PVC Pipes

PVC pipes come in a variety of grades and manufactured types, each suited for specific applications and conditions. Understanding their specs and typical lifespan can help you choose the right one with the right performance for your project.

Schedule 40 PVC Pipe

Schedule 40 PVC pipe is perhaps the most widely used type, known for its versatility and affordability, and general suitability for residential, agricultural, and light duty applications.

- Expected Lifespan: Under normal conditions, Schedule 40 PVC pipe can last 50 – 75 years, given it is properly installed and maintained. This long service life can be attributed to its resistance to corrosion, rust, and most chemicals found in residential plumbing, irrigation systems, and light industrial activities.

- Common Applications: This pipe grade is commonly used for water distribution, indoor and outdoor irrigation systems, waste handling, drainage, and vent piping. Since these applications generally do not demand high pressures or greater chemical resistance, Schedule 40 often meets or exceeds the expectations for durability and performance while offering overall lower costs.

Schedule 80 PVC Pipe

Schedule 80 PVC pipe is engineered for more demanding work conditions due to its thicker walls and the additional strength they provide to handle higher liquid pressures.

- Expected Lifespan: Designed for high performance applications, Schedule 80 PVC has an average lifespan of approximately 50 years. Its thicker walls not only increase its ability to withstand elevated liquid pressures but also provide better resistance to external impacts.

- Applications and Durability: Frequently employed in industrial and commercial pipelines, Schedule 80 PVC is ideal for high pressure water systems, chemical transport, and applications that require greater physical durability. The extra wall thickness of SCH 80 PVC pipe helps to reduce the likelihood of cracking or breaking under these more strenuous working conditions.

- Compare SCH 40/80 PVC: To review the differences between SCH 40 and SCH 80 PVC, see our resource to Compare Schedule 40 and Schedule 80 Pipe and Fittings.

CPVC Pipe

Chlorinated Polyvinyl Chloride (CPVC) is a specialized grade of PVC designed to withstand even harder working conditions, particularly in terms of temperature and chemical compatibility.

- Expected Lifespan: CPVC pipe has a lifespan ranging from 40 – 50 years, with excellent performance in applications involving high heat or corrosive chemicals. When used in residential or industrial hot water systems, Schedule 80 CPVC pipe will maintain its structural integrity longer than typical PVC due to its better thermal resistance.

- Specialized Applications: CPVC is often used for hot water plumbing, industrial chemical transport, chemical waste handling, fume scrubbers, ventilation systems, and fire sprinkler systems. Unlike traditional PVC, CPVC can handle temperatures up to 200°F without deformation, making it particularly valuable in jobs where heated solutions are necessary to operations. Its greater resistance to corrosive fluids like strong acids and alkalis further solidifies its role in chemical heavy applications.

- More on CPVC: For details on CPVC material, read What is CPVC?

- Comparing CPVC: To compare PVC and CPVC, see our article CPVC vs PVC.

- CPVC Chemical Use: For info and a list of recommended and not recommended chemicals for CPVC, see our CPVC Chemical Compatibility Guide.

Furniture Grade PVC Pipe

Furniture grade PVC pipes are typically used for non pressure, non liquid projects like DIY furniture, recreational equipment, and lightweight structures.

- Expected Lifespan: The lifespan of furniture grade PVC can vary significantly based on environmental conditions. Indoors, where the pipe is shielded from UV rays and extreme temperatures, it can last for decades. However, outdoor use of low quality furniture pipe can shorten its lifespan due to sunlight exposure that, without protection, will weaken the material over time.

- Usage Considerations: Since furniture grade PVC is not designed for pressure or fluid transport applications, its durability comes down to the structural load, external physical stressors, and environmental exposure. Projects using this pipe indoors or sun safe premium furniture grade PVC pipe typically experience excellent longevity.

To summarize, the lifespan of PVC pipe depends on the specific type of pipe and the conditions it is exposed to. Schedule 40 pipes offer lasting durability (50–75 years) for residential and irrigation uses, while Schedule 80 pipes deliver reliable performance for higher pressure distribution and industrial systems. CPVC pipe provides excellent results in demanding applications like hot water and chemical conveyance pipelines, and furniture grade PVC excels for creative projects with a multi-decade service potential. By selecting the right type of PVC according to its intended purpose and maintaining it, you can ensure your plumbing investment delivers many years of dependable service.

Common Causes of Wear and Tear

PVC pipes are widely known for their versatile strength and resilience against many environmental and chemical challenges. However, like all materials, they are not immune to wear and tear. Recognizing the common causes of degradation can help contractors and homeowners take preventative steps to maximize the lifespan of their PVC pipelines. Below are the primary causes of wear and tear in PVC pipes.

UV Degradation

Prolonged exposure to sunlight can pose a significant threat to the integrity of outdoor PVC pipes, largely for those that are not manufactured with UV stabilizers.

- How It Happens: When exposed to ultraviolet (UV) rays over an extended period, the molecular structure of unprotected PVC begins to break down. This process, known as photodegradation, weakens the pipe material and causes it to lose its elasticity and physical strength, leading to cracks and embrittlement. The pipe’s surface may appear chalky, faded, or yellow, all of which are signs of UV damage.

- Prevention: To counteract sunlight UV damage, use UV stabilized PVC pipes or CPVC pipes for outdoor installations. These are often gray to black in color. Additional options are to apply a light colored, UV resistant acrylic, plastic approved paint or install an insulating cover around the pipes to protect them from sunlight.

Chemical Corrosion

The inherent properties of PVC and CPVC, and the pipes and fittings made from them, allow them to handle a variety of chemicals, but using pipes not rated for specific chemicals can lead to rapid deterioration and service loss.

- The Corrosive Impact: Harsh and reactive chemicals such as concentrated acids, alkalis, solvents, and various organic solutions can erode the internal surface of the pipe, cause swelling, or soften the material, weakening its structure and leading to leaks or complete failure. Over time, even mild chemicals will create wear if the pipe is rated with low compatibility.

- Avoiding This Issue: To avoid corrosion concerns, select PVC pipes with appropriate chemical resistance ratings for the fluids and liquid temperatures they will carry. Consult a compatibility chart before installation to ensure the selected pipe material can handle the intended fluids.

Improper Handling or Installation

Improper installation or mishandling of PVC pipes is a common and entirely avoidable cause of premature failure.

|  |

- Misalignment and Poor Cementing: Pipes that are not properly aligned during installation are more susceptible to stress at the connection points. Similarly, failing to use enough solvent cement or poor application can leave joints vulnerable to separation and leaks.

- Insufficient Support: Without adequate support, pipes may sag under their own weight, especially in suspended horizontal installations. The added stress, particularly in long runs, can cause cracking or joint failure.

- Best Practices: During installation, take the time to carefully align, properly join pipes using high quality cement and primer, andallow the recommended set time before testing and use. Incorporate adequate bracing and clamps, such aspipe hangers, to ensure the system remains well supported so it minimizes stress on joints.

Physical Damage

Physical impacts during transportation, storage, or daily operation can quickly compromise the structural integrity of PVC pipes.

- Crushing and Punctures: PVC pipes are flexible but not impervious to damage from external force. Dropping, dragging, or crushing pipes during handling can cause microfractures invisible to the eye, which may worsen during regular use. Similarly, punctures from sharp objects can directly damage the pipe and will require replacement.

- Preventing Damage: Handle PVC pipes with care during loading, unloading, and installation. Store them in a safe location, away from heavy equipment or sharp tools.

Aging and Time

Even the most well maintained PVC systems will eventually show signs of aging.

- The Effects of Time: Over decades, PVC material can lose its flexibility and become brittle. This is particularly likely if the pipes have been exposed to hard working conditions, sunlight, or chemicals for extended periods. Brittle pipes are more prone to cracking and breaking during use or from impact.

- Extending the Lifespan: Regular inspections can help identify early signs of aging, such as small cracks and discoloration. While aging cannot be prevented entirely, replacing segments of the system as they express signs of aging can delay the need for a complete overhaul.

By understanding the common causes of PVC pipe wear and tear — UV degradation, chemical incompatibility, improper handling, physical damage, and natural aging — contractors, homeowners, and DIY enthusiasts can take proactive steps to safeguard their PVC piping systems. With proper material selection, careful installation, and ongoing maintenance, PVC pipes can deliver reliable performance for decades with minimal downtime and replacement costs.

Maintenance Tips to Extend PVC Pipe Lifespan

Similar to any working item or system, PVC pipes require proper maintenance, use, and care to maximize their lifespan. Simple preventative measures can not only extend the usability of your piping system but also ensure that it continues to operate safely and efficiently. Here are some key maintenance tips to help preserve the integrity of your PVC pipes.

Protect Pipes from UV Exposure

When PVC pipes are installed outdoors, direct sunlight can become a leading factor in their wear and tear. Prolonged UV exposure gradually weakens the material, leading to surface degradation and brittleness.

- Use Insulating Covers: Installing insulating covers around exposed outdoor pipes provides a layer of protection against sunlight while also insulating against temperature fluctuations.

- Apply UV Resistant Paints: A simple and effective solution is to paint exposed pipes with a light colored, UV resistant acrylic paint rated for plastics. This will not only block UV rays but also help reflect heat and reduce the thermal stress on the pipes.

These measures greatly reduce the risk of photodegradation.

Routine Inspections

Regular inspections of a PVC piping system can help catch minor issues before they turn into major problems.

- What to Look For: During routine checks, examine the pipes for signs of surface damage, such as cracks, discoloration, or loose fittings. Pay close attention to joints and connection points, as these are common areas for leaks and stress cracking.

- Frequency of Inspections: Conduct inspections at least once a year for residential systems or more frequently for industrial applications that operate under high pressure or heavy chemical exposure.

Avoid Overpressurizing Pipes

Every type of PVC pipe has a specified pressure rating that determines how much internal force it can safely handle. Exceeding these limits can cause cracking, joint failure, or even bursting under extreme conditions.

- Stay Within Pressure Ratings: Always refer to the manufacturer’s pressure-temperature chart and make sure operating pressures do not exceed the recommended limits.

- Reduce Pressure Stress: For systems with fluctuating pressures, consider installing pressure regulators to stabilize the forces within the pipe, as this can help minimize stress and prevent unnecessary damage.

Prevent Chemical Damage

PVC pipes have good chemical resistance, but using the wrong type of PVC for specific substances can lead to damage which can lead to premature or catastrophic failure.

- Match Materials to Chemicals: Consult chemical compatibility charts or the manufacturer to determine whether your PVC or CPVC pipe is suitable for the material it will transport. For example, standard PVC may fail against aggressive acids or solvents, while CPVC is often better suited for these liquids.

- Flush Residual Chemicals: If the pipeline will handle different chemicals at different times, perform a thorough flush between uses to prevent residual chemicals that could cause unwanted reactions and damage.

Secure, Proper Installation

Poorly installed pipes are far more likely to experience early failure, making expert handling and secure, proper installation essential.

- Seal Joints Correctly: Use high quality solvent cement and primer for secure, leakproof connections. Ensure joints are free from debris and correctly aligned before bonding.

- Provide Adequate Support: Install pipe supports at regular, recommended intervals based on pipe length and diameter to prevent sagging, bending, or collapse. If unsupported pipes are found during an inspection, promptly fix the problem — pipe hangers are quick and easy to install, even on pre-existing pipelines.

- Focus on Alignment: Misaligned pipes will create uneven load displacement that can accelerate wear due to vibration and pressure. Ensure all segments are correctly aligned and fix any necessary connections. Also, useflexible couplings when segments don’t perfectly align or to account for minor movements in the plumbing system due to equipment and operation.

Maximizing the lifespan of PVC pipes requires attentive maintenance and proactive measures. Protect outdoor pipes from UV exposure using insulating covers, paint, or UV stabilized pipe, perform regular inspections to catch early signs of wear, and always operate within rated pressure limits. Ensure chemical compatibility and follow proper installation techniques. With these steps in place, your PVC pipes can deliver decades of reliable performance.

Signs That a PVC Pipe Needs Replacement

PVC pipes are designed to last for decades, but no material will last indefinitely. While proper maintenance can extend service life, certain signs can indicate a pipe may need replaced. Identifying issues early can prevent more serious problems and collectively save time, effort, and money. Below are the key signs that a PVC pipe needs replacement.

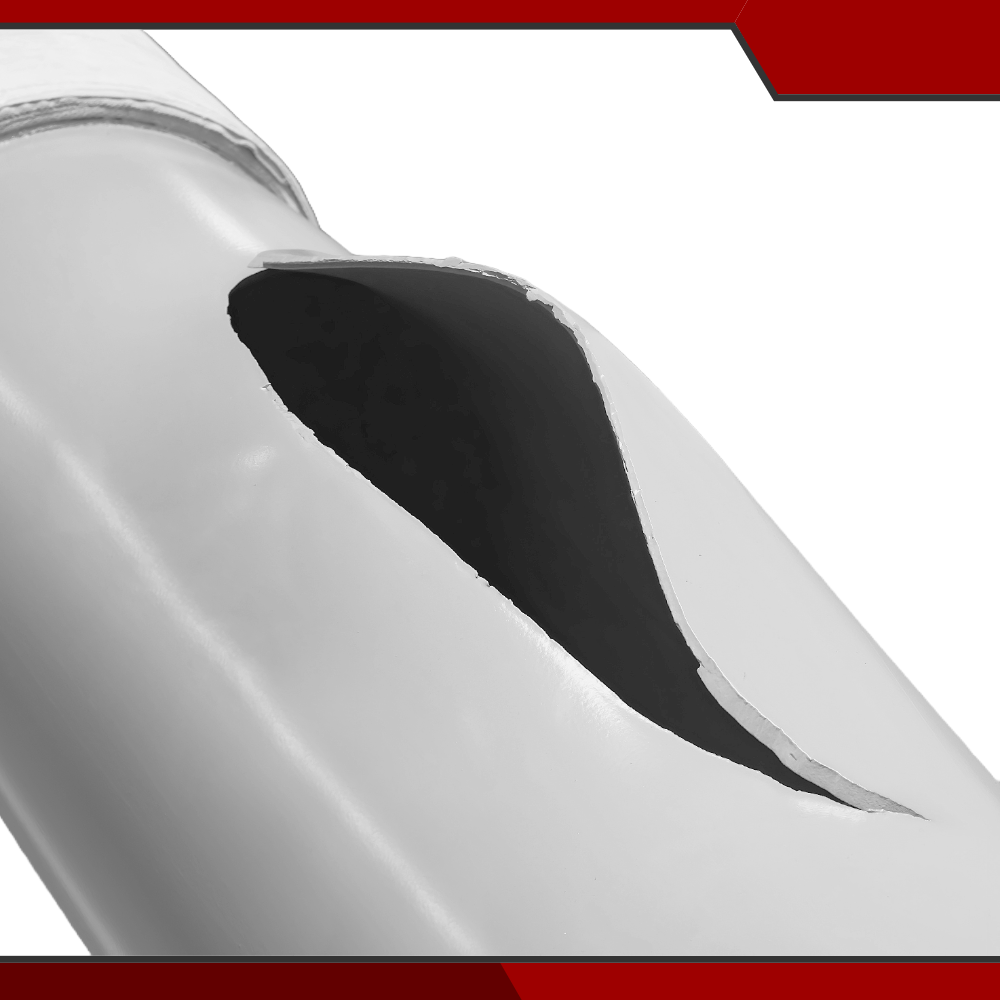

Visible Cracks or Leaks

One of the clearest signs that a PVC pipe may need replacing is the presence of visible cracks or leaks.

- Material Fatigue: Cracks often form as a result of years of pressure, temperature fluctuations, or physical impacts. Even small cracks can grow larger under repetitive use, eventually causing leaks or water damage.

- Signs to Watch For: Inspect your pipes regularly for hairline cracks, liquid drips, or pooling near joints and fittings. Ignoring these early signs could lead to full pipe failure and costly repairs.

Discoloration or Brittleness

Environmental exposure can have a long lasting effect on PVC pipes that alters both its appearance and reliability.

- Impact of UV and Chemical Exposure: Unprotected pipes exposed to sunlight may become discolored, turning yellowish or chalky white. This discoloration is often accompanied by brittleness, making the pipe fragile, as prolonged exposure to ultraviolet energy breaks down the pipe’s molecular structure.

- Flexibility Loss: A brittle pipe is less resilient to load and physical stress and is far more likely to crack or break during use. If you notice discoloration, consider replacing the pipe or fitting before it fails completely.

Fluid Pressure Changes

Fluctuations in fluid pressure, especially sudden drops, can be another indication of a failing PVC pipe.

- Potential Causes: Leaks caused by cracks or internal damage can lower pressure throughout the system. Also, blockages within the pipe due to material buildup or damage can restrict flow, causing pressure loss.

- Assessing the Problem: If pressure issues persist, inspect accessible sections of the pipe for visible damage. If the issue is within buried or hidden pipes, uncovering or professional diagnostic tools like pressure gauges or video inspections may be necessary to locate the problem.

- Install Accessories: Usepressure gauges orliquid flow meters to monitor system dynamics and operation, allowing for regular monitoring of fluctuations or problems.

Recurring Repairs

Frequent repairs to the same section of a PVC pipeline can mean that the pipe has outlived its usefulness.

- When Maintenance Adds Up: Repeated leaks, joint failures, or other issues often indicate material fatigue. At this point, replacing the problematic section of piping may be more cost effective and secure than performing ongoing repairs.

- Proactive Replacement: If you find yourself repeatedly patching the same issues, consider upgrading to newer, more durable piping material for better reliability and peace of mind.

Pipe Noise or Vibration

Strange sounds or excessive vibrations can be subtle but important indicators of structural instability within a PVC plumbing system.

- Common Causes: Noises such as rattling, banging, or whistling often result from loose or poorly supported pipes, bad connections, or equipment malfunctions. Over time, this instability can place strain on joints and other connection points that can cause further problems.

- What to Inspect: Check for loose fittings, loose pipe lengths, misaligned segments, or worn out pipe clamps or hangers that fail to secure properly.

Knowing when it’s time to replace PVC pipes will help avoid larger system failures and significant repair costs. Monitor for visible cracks and leaks, discolored or brittle surfaces, and sudden changes in pressure. Recurring repairs and strange noises should raise red flags about the pipe’s condition. By taking these signs seriously and addressing them promptly, you can maintain a safe plumbing system that meets the demands of your project or property.

Support from PVC Pipe Supplies

When it comes to choosing and getting the most out of your PVC pipes, expert guidance and access to professional grade products are invaluable. PVC Pipe Supplies is your one-stop solution for all things PVC with — an exceptional range of modern product types, sizes, and accessories — expert support — low price guarantee — and contractor quote options for larger projects.

Recommending Products

The team at PVC Pipe Supplies can help you identify the ideal pipe for your specific needs. Whether you’re working on a light residential project, a heavy duty industrial system, or a custom structure, our inventory covers a wide range of pipes and fittings, including Schedule 40, Schedule 80, CPVC, furniture grade PVC, duct pipe, DWV pipe, and more.

Not sure which pipe type suits your project? PVC Pipe Supplies’ experienced customer support team is equipped with the knowledge to guide you.

Bulk Orders

For large scale projects, PVC Pipe Supplies also providesbulk order options. Contractors and industry professionals can take advantage of this to reduce per-unit costs to make or undershoot budgets. This is especially beneficial for commercial jobs or long term maintenance contracts where the savings add up over time.

Why Choose PVC Pipe Supplies?

When it comes to sourcing quality plumbing, choose a supplier who understands your specific needs. PVC Pipe Supplies offers a comprehensive inventory backed with dedicated service and savings to ensure you get the best value for your investment.

When choosing materials for your next project, trust the experts at PVC Pipe Supplies to provide high quality PVC solutions and professional support. From product recommendations to contractor purchasing options, we have everything you need for the success and long service life of your piping systems. VisitPVC Pipe Supplies today to explore our inventory — take proactive steps today for a worry-free tomorrow.