Handling harsh chemicals requires more than just careful planning; it demands the right materials that can withstand the exact conditions. Choosing the wrong material could result in equipment damage from corrosion, swelling or dissolution, system failure, or even costly downtime. Among available plumbing options, CPVC (Chlorinated Polyvinyl Chloride) pipe stands out as a premium and professional choice. Known for its exceptional chemical resistance, general durability, and reliability, CPVC has become a trustworthy material across industries that need to safely manage corrosive substances.

Common Chemicals CPVC is Compatible With

CPVC pipe has a broad chemical resistance that makes it an ideal option for transporting a wide variety of liquids. Its ability to withstand harsh acids, difficult bases, leak-prone caustics, industrial salts, and strong oxidizers sets it apart for demanding chemical environments. Here we’ll look at the most common chemicals CPVC pipe is compatible with and highlight their applications.

Acids

CPVC pipe and fittings perform exceptionally well when exposed to many commonly used acids. Top examples include:

- Hydrochloric Acid (HCl): Widely used in industrial cleaning systems, chemical processing, and manufacturing plants, CPVC has recommended approval and excellent resistance that ensures long term reliability with varying concentrations of this highly corrosive substance.

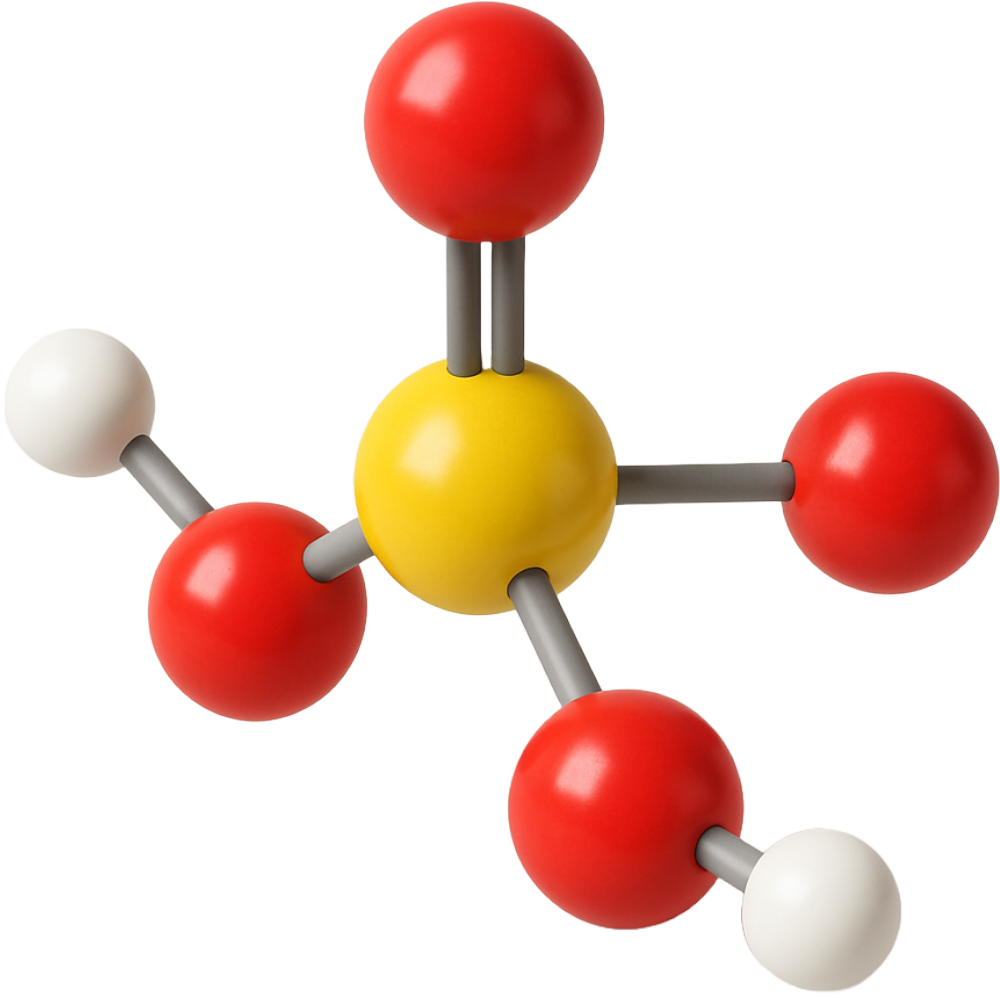

- Sulfuric Acid (H₂SO₄): Highly compatible with CPVC at concentrations up to 98%, sulfuric acid is often used in battery production and mineral processing operations.

- Phosphoric Acid (H₃PO₄): Common in fertilizers and surface cleaning agents, CPVC pipe and fittings offer excellent compatibility with phosphoric acid in transport and storage.

Bases/Alkaline Liquids

CPVC is highly resistant to many bases and alkaline compounds, with the most common examples including:

- Sodium Hydroxide (NaOH): Commonly used in soap production, water treatment, and cleaning applications, CPVC easily handles the caustic and “leaky” properties of sodium hydroxide.

- Potassium Hydroxide (KOH): Often utilized in biodiesel manufacturing, industrial cleaning, and various production applications, CPVC has the durability to ensure safe handling of this base.

Salts

Among solution types, CPVC has perhaps the best resistance and compatibility with saline solutions and industrial salts due to the chlorinated structure of its material composition. This makes CPVC highly versatile for water treatment and other industries that utilize salt compounds and mixtures.

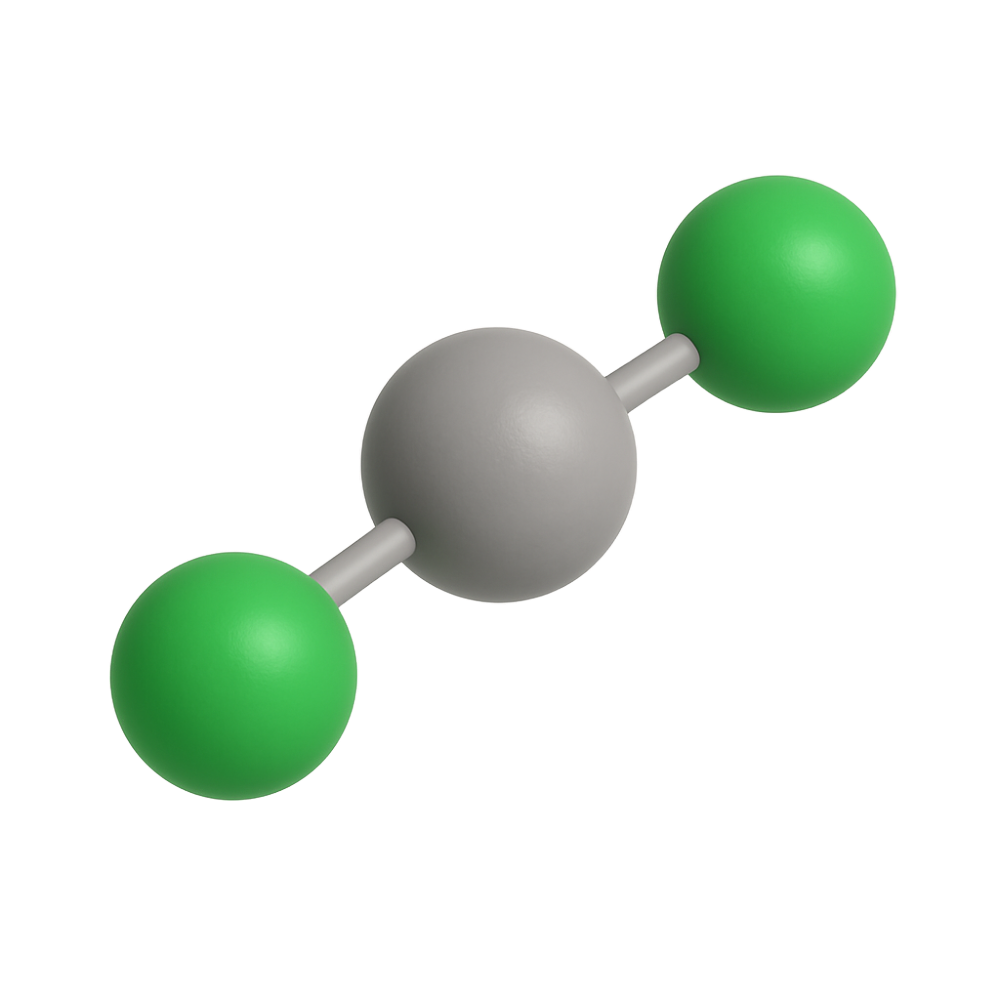

- Sodium Chloride (NaCl): Frequently used in brine systems, desalination plants, and deicing applications, CPVC pipe and fittings remain unaffected by the corrosive effects of water with high salt content.

- Calcium Chloride (CaCl₂): Common in deicing applications, food processing, cooling towers and refrigeration, CPVC offers stability even under prolonged exposure.

Oxidizers and Disinfectants

CPVC piping is widely used to handle cleaning agents and in water treatment systems due to its resistance to degradation from oxidizing agents and disinfectants.

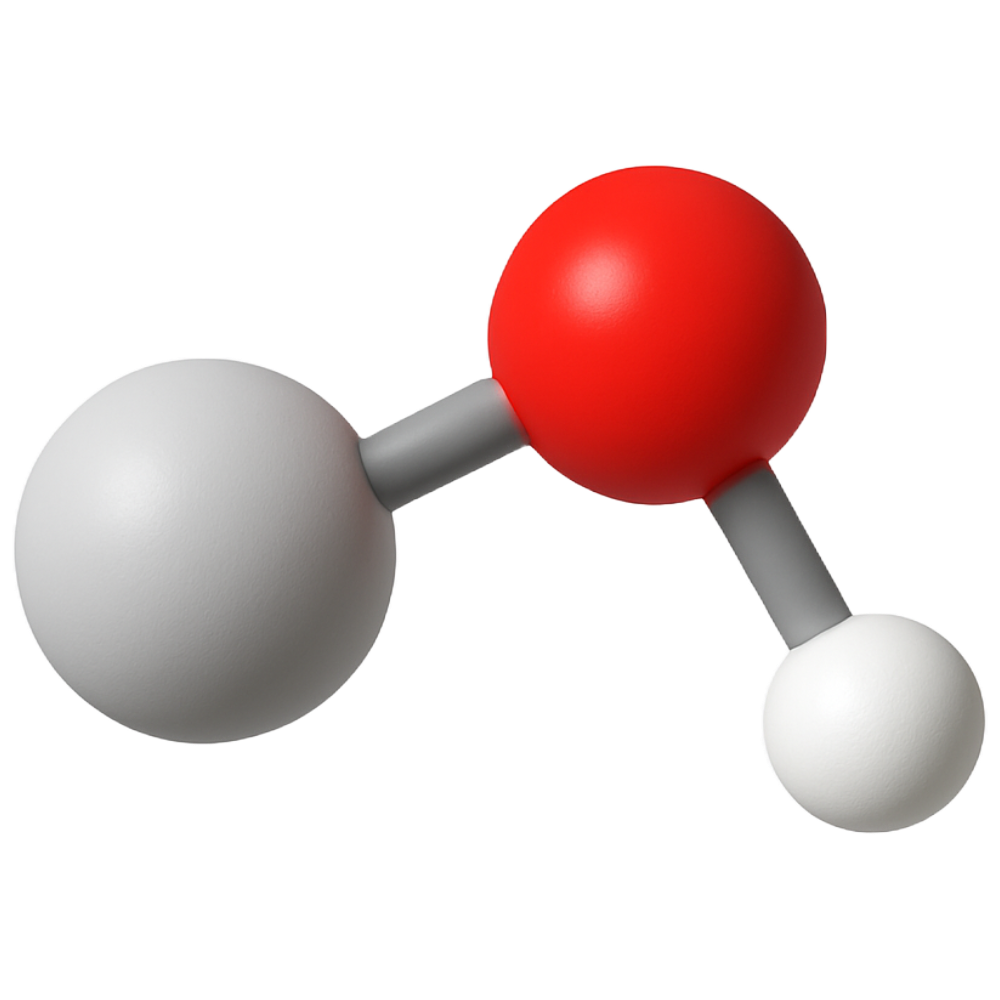

- Hydrogen Peroxide (H₂O₂): Commonly used for disinfection and in textile bleaching, CPVC keeps its strength even under repetitive exposure.

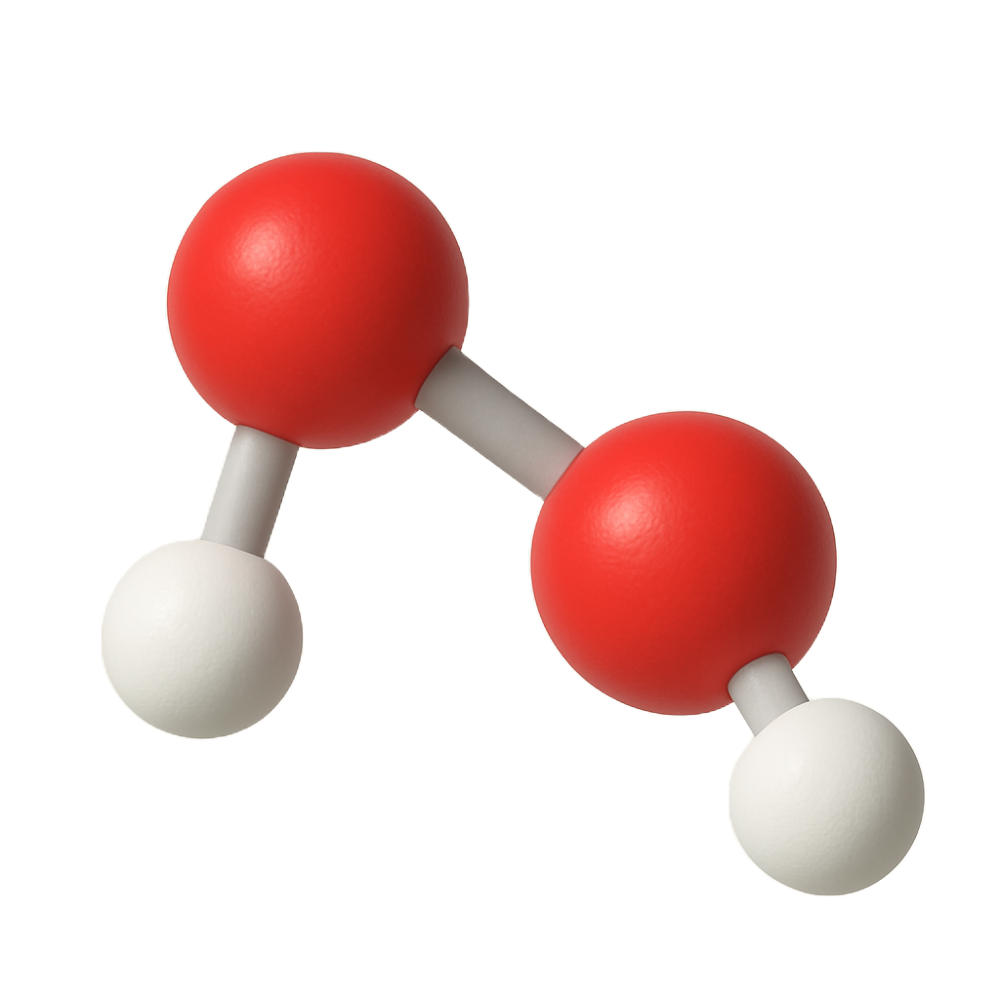

- Chlorinated Water: CPVC plumbing is widely used in municipal water treatment and swimming pool systems to handle bleach solutions up to 15% strength.

Organic Compounds

Organics can sometimes present challenges for CPVC and other synthetic plumbing materials. This makes it vital to verify chemical compatibility between the pipe and chemical prior to use. CPVC demonstrates compatibility with select organic compounds, with the most common including:

- Ethylene Glycol: Key ingredient for industrial cooling and antifreeze solutions, CPVC remains stable in concentration levels of up to 50%.

- Methanol (up to 10%): Often found in solvents and industrial fuels, CPVC provides reliable performance without softening or swelling.

Other Compatible Chemicals

Other common chemicals CPVC is compatible with include:

- Ammonium Nitrate: A key component in fertilizers, CPVC pipe is ideal for agricultural storage and transport systems.

- Citric Acid: Extensively used in food production and cleaning, CPVC resists the mild corrosive effects of this organic acid.

CPVC Chemical Compatibility Tables

The CPVC chemical compatibility tables below categorize chemicals into recommended and non-recommended options for use with CPVC pipe and fittings. These comprehensive references are designed to assist in material selection and reduce the likelihood of chemical corrosion or system failure.

This data is sourced from Lubrizol Advanced Materials, the manufacturer of Corzan™ CPVC, the material used in most of our CPVC pipe and fittings. The data is provided for recommendation purposes only, and is accurate to the best of our knowledge; no guarantee is warranted or implied. If uncertainty exists, always seek out specialized, professional guidance.

Recommended Chemicals for CPVC

The following table is a list of chemicals recommended for CPVC pipe and fittings:

| Chemical | Chemical | Chemical | Chemical | Chemical |

| Acetic Acid (up to 10%) | Adipic Acid | Aluminum Acetate | Aluminum Chloride | Aluminum Fluoride |

| Aluminum Hydroxide | Aluminum Nitrate | Aluminum Sulfate | Ammonium Acetate | Ammonium Benzoate |

| Ammonium Bifluoride | Ammonium Carbonate | Ammonium Chloride | Ammonium Citrate | Ammonium Dichromate |

| Ammonium Fluoride | Ammonium Nitrate | Ammonium Persulfate | Ammonium Phosphate | Ammonium Sulfamate |

| Ammonium Sulfate | Ammonium Sulfide | Ammonium Tartrate | Ammonium Thiocyanate | Anthraquinone |

| Antimony Trichloride | Aqua Regia | Arsenic Acid | Barium Carbonate | Barium Chloride |

| Barium Hydroxide | Barium Nitrate | Barium Sulfate | Barium Sulfide | Benzoic Acid |

| Bleach, Household (5% Cl) | Bleach, Industrial (15% Cl) | Borax | Boric Acid | Bromic Acid |

| Bromine, aqueous, sat’d | Calcium Acetate | Calcium Bisulfide | Calcium Bisulfite | Calcium Carbonate |

| Calcium Chlorate | Calcium Chloride | Calcium Hydroxide | Calcium Hypochlorite | Calcium Nitrate |

| Calcium Oxide | Calcium Sulfate | Citric Acid | Copper Acetate | Copper Carbonate |

| Copper Chloride | Copper Cyanide | Copper Fluoride | Copper Nitrate | Copper Sulfate |

| - | Ferric Chloride | Ferric Hydroxide | Ferric Nitrate | Ferric Sulfate |

| Ferrous Chloride | Ferrous Hydroxide | Ferrous Nitrate | Ferrous Sulfate | Hydrogen Peroxide (30%-50%) |

| Hydrochloric Acid | Phosphoric Acid | Potassium Hydroxide | Sea Water | Silicic Acid |

| Silicone Oil | Silver Chloride | Silver Cyanide | Silver Nitrate | Silver Sulfate |

| Sodium Acetate | Sodium Aluminate | Sodium Arsenate | Sodium Benzoate | Sodium Bicarbonate |

| Sodium Bichromate | Sodium Bisulfate | Sodium Bisulfite | Sodium Borate | Sodium Bromide |

| Sodium Carbonate | Sodium Chlorate | Sodium Chloride | Sodium Chlorite | Sodium Chromate |

| Sodium Cyanide | Sodium Dichromate | Sodium Ferricyanide | Sodium Ferrocyanide | Sodium Fluoride |

| Sodium Fluorosilicate | Sodium Formate | Sodium Hexametaphosphate | Sodium Hydroxide | Sodium Hypobromite |

| Sodium Hypochlorite | Sodium Iodide | Sodium Metabisulfite | Sodium Metaphosphate | Sodium Nitrate |

| Sodium Nitrite | Sodium Palmitate | Sodium Perborate | Sodium Percarbonate | Sodium Perchlorate |

| Sodium Permanganate | Sodium Phosphate | Sodium Silicate | Sodium Sulfate | Sodium Sulfide |

| Sodium Sulfite | Sodium Thiosulfate | Sodium Tripolyphosphate | Soybean Oil | Stannic Chloride |

| Stannous Chloride | Stannous Sulfate | Starch | Stearic Acid | Strontium Chloride |

| Sugar | Sulfamic Acid | Sulfur | Sulfur Dioxide (Aqueous) | Sulfuric Acid (50%-98%) |

| Sulfurous Acid | Tannic Acid (30%) | Tartaric Acid | Tetraacetyl Ethylene Diamine (Saturated) | Tetrasodium Pyrophosphate |

| Tomato Juice | Trisodium Phosphate | Tung Oil | Urine | Vegetable Oil |

| Vinegar | Water (Deionized, Demineralized, Distilled, Salt) | Whiskey | White Liquor | Wine |

| Zinc Acetate | Zinc Carbonate | Zinc Chloride | Zinc Nitrate | Zinc Sulfate |

Not Recommended Chemicals for CPVC

The following table is a list of chemicals not recommended for CPVC pipe and fittings.

| Chemical | Chemical | Chemical | Chemical | Chemical |

| Acetaldehyde | Acetic Acid (Glacial) | Acetone | Acetophenone | Acetyl Chloride |

| Acrylic Acid | Acrylonitrile | Allyl Chloride | Ammonia (28%) | Amyl Acetate |

| Amyl Chloride | Aniline | Benzaldehyde | Benzene | Benzyl Chloride |

| Bromine | Butyl Acetate | Butyl Carbitol™ | Butyl Cellosolve™ | Carbon Disulfide |

| Carbon Tetrachloride | Chloroacetic Acid | Chlorobenzene | Chloroform | Cresol |

| Cyclohexanone | Diacetone Alcohol | Dibutyl Ether | Dibutyl Phthalate | Dichlorobenzene |

| Dichloroethylene | Diethyl Ether | Dimethyl Phthalate | Dimethylformamide | Dioxane |

| Ethanol (Pure) | Ethyl Acetate | Ethyl Acrylate | Ethyl Benzene | Ethyl Chloride |

| Ethylene Bromide | Ethylene Chloride | Ethylene Diamine | Ethylene Glycol (Pure) | Ethylene Oxide |

| Formaldehyde | Freons | Gasoline | Glycolic Acid | Halocarbon Oils |

| Hydrazine | Isopropanol (Pure) | Kerosene | Limonene | Methanol (Pure) |

| Methyl Acetate | Methyl Ethyl Ketone | Methylene Chloride | Nitrobenzene | Nitroglycerine |

| Oleum | Peracetic Acid | Phenylhydrazine | Propylene Dichloride | Pyridine |

| Styrene | Tetrahydrofuran (THF) | Toluene | Trichloroethylene | Turpentine |

| Vinyl Acetate | Xylene |

Industry Applications

The exceptional chemical resistance and durability of CPVC pipelines make it an indispensable material and plumbing type across various industries and applications. Here are the top, large scale industries that benefit directly from CPVC’s chemical compatibility:

- Chemical Processing Plants: CPVC is employed heavily in chemical processing facilities where harsh fluids, like hydrochloric acid and caustic soda, are handled. Its ability to resist corrosion and maintain its performance metrics delivers safety and reliability to these demanding work conditions and environments.

- Water Treatment Facilities: Water treatment facilities utilize CPVC to safely transport chlorinated water, sodium hypochlorite, and various other treatment solutions. CPVC's resistance to oxidizers, disinfectants, and inorganic compounds makes it ideal for the long term integrity and maintenance of these vital systems.

- Food and Beverage Industry: CPVC’s compatibility with mild acids, like citric acid, food grade materials, and ingredients, like sodium bicarbonate, makes it suitable and frequently used in food production settings. Its non-toxic nature and general corrosion resistance ensure safety and cleanliness.

- Pharmaceuticals: The pharmaceutical industry takes advantage of CPVC's compatibility with hydrogen peroxide, phosphoric acid, and various solvents. This combination of durability and chemical resistance supports safe manufacturing, cleaning, and storage activities.

Takeaway

CPVC has proven to be a reliable material for handling a wide variety of chemicals that are used across numerous applications in today’s industries. The ability of CPVC pipe and fittings to resist acids, bases, salts, oxidizers, and various organic compounds is set to ensure safe and lasting performance low stress to high hazard fluid conveyance networks.

When it comes to safely managing aggressive chemicals, CPVC is a modern material option that combines durability, reliability, and exceptional chemical resistance. Using CPVC to create plumbing systems can improve both safety and longevity, making it a smart choice for various applications.

Explore our selection of CPVC pipe and CPVC fittings. Contact PVC Pipe Supplies today to learn more, request contractor pricing, or get expert guidance on your next project.