|

Choosing the right material for a plumbing system is one of the most lasting and sometimes uncertain decisions a contractor or builder can make. The pipes hidden behind the walls determine a system's long term reliability, water quality, and overall performance. A poor choice can lead to premature failures, costly repairs, and significant property damage, while the right material can ensure decades of dependable service. Aside from PVC pipe, two of the most common plastic piping materials on the market today are CPVC and PEX. Both are widely used in residential and commercial plumbing, but they have different properties that impact their performance, installation, and durability. While each has its place, understanding their advantages and limitations will let you make the best decision for protecting your investment or your job and reputation. This guide provides an in-depth comparison of CPVC and PEX, examining everything from material composition and chlorine resistance to flow rates and service life cost effectiveness. Our goal is to cut through the debate and highlight why CPVC often stands out as the superior choice for projects that demand reliability and the highest water quality. |

What Are CPVC and PEX Pipes?

Before going into a direct comparison, let’s review each material and how its independent properties influence its performance in a plumbing system.

CPVC (Chlorinated Polyvinyl Chloride)CPVC is a thermoplastic produced by the chlorination of a standard PVC resin to change its chemical structure and properties. This additional chlorine at the molecular level gives CPVC pipe its enhanced durability, chemical resistance, and ability to withstand higher temperatures and pressures over standard PVC. The material is rigid, strong, and has a long history of reliable performance across common, low demand, and heavy duty uses. |

|

CPVC (Chlorinated Polyvinyl Chloride)

CPVC is a thermoplastic produced by the chlorination of a standard PVC resin to change its chemical structure and properties. This additional chlorine at the molecular level gives CPVC pipe its enhanced durability, chemical resistance, and ability to withstand higher temperatures and pressures over standard PVC. The material is rigid, strong, and has a long history of reliable performance across common, low demand, and heavy duty uses.

- Key Properties: CPVC is defined by its inherent resistance to chlorine and other disinfectants, which prevents the pipe from degrading over time when handling such liquids. Its rigid structure provides a straight, professional installation appearance and contributes to its durability. CPVC pipe is standardized and approved for both hot and cold potable water systems, with a high temperature tolerance that makes it a safe choice for water heaters and other hot water applications.

- Common Applications: Due to its overall robust nature, CPVC pipe is widely used in residential, commercial, and industrial plumbing systems. It is a preferred material, approved by building and plumbing codes, for hot and cold water distribution lines, water treatment facilities, and various chemical handling processes.

PEX (Cross Linked Polyethylene)PEX is a flexible plastic pipe made from cross linked polyethylene. The cross-linking process creates a different material from standard polyethylene with improved strength and temperature resistance. PEX is known for its flexibility, which allows it to be bent around corners, snaked through walls, and often reduces the number of fittings required. |

|

PEX (Cross Linked Polyethylene)

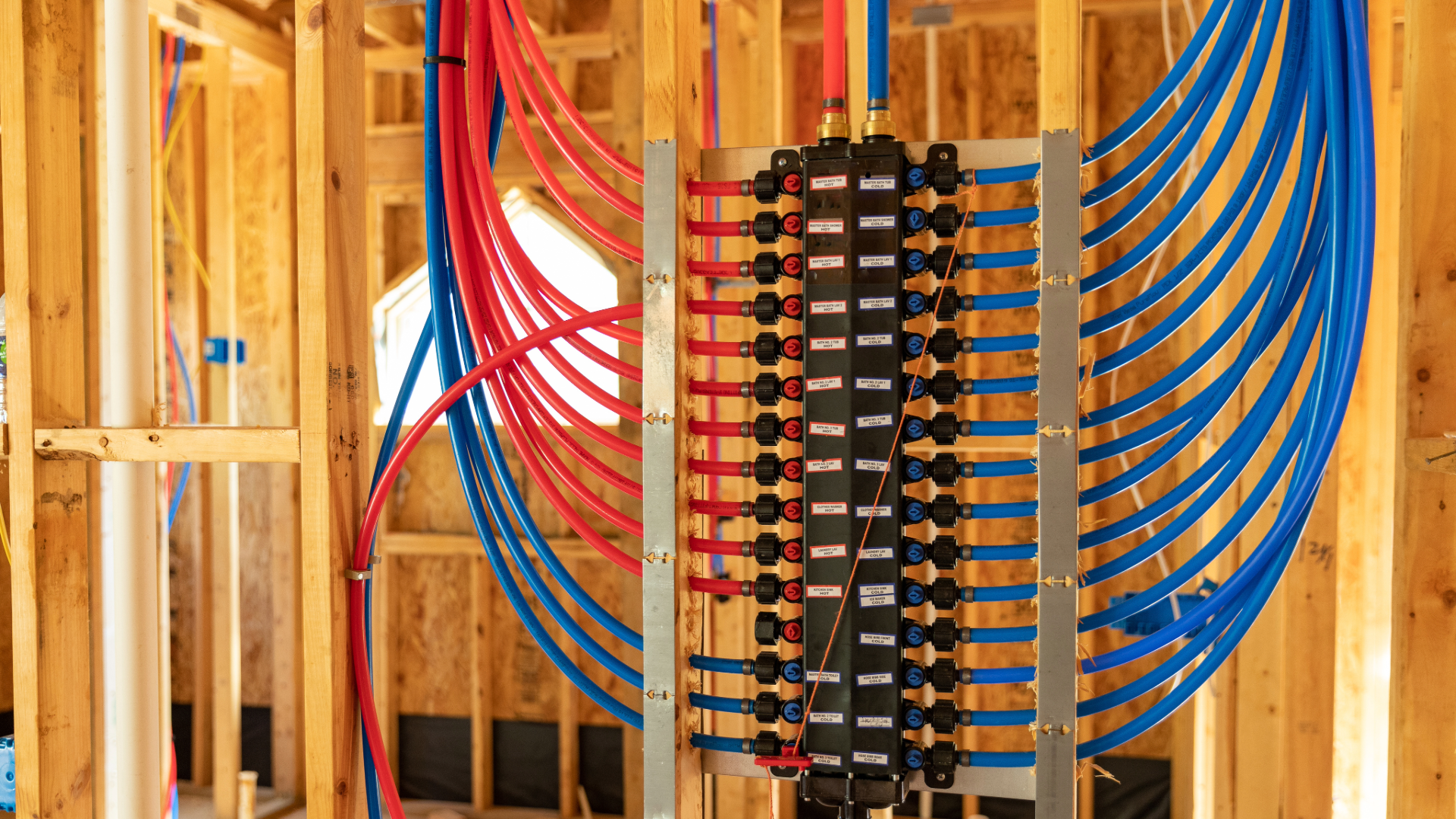

PEX is a flexible plastic pipe made from cross linked polyethylene. The cross-linking process creates a different material from standard polyethylene with improved strength and temperature resistance. PEX is known for its flexibility, which allows it to be bent around corners, snaked through walls, and often reduces the number of fittings required.

- Key Properties: The standout feature of PEX pipe is its flexibility, which can simplify and speed up the installation process, particularly in retrofits. It can also be generally less expensive upfront than some other materials and is resistant to scale and corrosion concerns common with copper pipe.

- Common Applications: PEX is primarily used in residential plumbing for hot and cold water supply lines. Its flexibility also makes it a popular choice for radiant floor heating systems, where the pipe is embedded in concrete slabs.

Key Differences: CPVC vs. PEX

While both CPVC and PEX are used similarly for hot and cold water distribution, their performance in these plumbing systems can be vastly different. These differences stem from their base material properties, installation methods, and long term behavior when exposed to common environmental conditions. Knowing these distinctions can make the difference between selecting the right pipe or the one that leaves you with a headache, wishing you had made the other choice.

Material Composition and Structure

The central difference between CPVC pipe and PEX pipe lies in their chemical and physical structure, which in turn, determines their overall rigidity, durability, and resistance to chemicals.

- CPVC: As a chlorinated thermoplastic, CPVC pipe is inherently rigid and strong. The additional chlorine makes it exceptionally resistant to the chlorine and chloramine commonly used in municipal water treatment. This ensures that CPVC does not become brittle or fail due to chemical damage over many years of use. Its rigidity also provides a clean, professional looking installation that won't sag or bend over time.

- PEX: PEX is a flexible polyethylene material that is lightweight and easy to bend. However, this flexibility comes with certain trade-offs. PEX pipe is not naturally resistant to chlorine and relies on antioxidants added during manufacturing to protect it. Over time, exposure to hot, chlorinated water can deplete these antioxidants, leaving the pipe vulnerable to cracking and pinhole leaks. PEX pipe is also highly susceptible to sunlight UV radiation damage, meaning even short term exposure to sunlight during storage or installation can compromise its integrity.

Installation Process

The installation methods for PEX and CPVC pipe are completely different. Each requires its own set of tools, techniques, and labor time.

- CPVC: CPVC pipes are joined using a simple, yet reliable solvent welding process. The process uses a primer and solvent cement to chemically fuse pipes and fittings together. The result is a seamless joint stronger than the pipe itself. The process requires inexpensive hand tools, such as a deburring tool and a pipe cutter. While the joints require a curing period (cement set time) before the system can be pressurized, the method is straightforward and creates a permanently bonded, leakproof system.

- PEX: PEX pipe installation involves mechanical fittings that are joined together, typically using either a crimping or expansion method. This requires specialized and often more costly tools. Although the installation can be faster since there is no curing time, the reliance on mechanical joints introduces potential failure points as improperly crimped rings or fittings can lead to slow leaks or catastrophic blowouts.

Cost Comparison

When looking at cost, you should go beyond the initial price per foot and consider the total cost of ownership, including tools, fittings, and any long term maintenance.

- CPVC: While the pipe itself may sometimes be comparable in price to PEX, the fittings for CPVC pipe are often less expensive. When combined with the low cost of solvent cement and basic hand tools, the overall material and installation cost for a CPVC system can be lower. Also, CPVC’s superior durability and chemical resistance translate to fewer repairs and a longer service life, in type, reducing lifespan maintenance costs.

- PEX: PEX tubing can appear cost effective upfront. However, the cost of specialized crimping or expansion tools and brass or plastic fittings can bring up the total project budget. And potential issues with chlorine degradation and leaching can cause the system to need replacing prematurely—making total cost of ownership significantly higher.

Lifespan Durability

Plumbing systems are an investment expected to last for decades, so the piping material's ability to withstand everyday working conditions is top priority.

- CPVC: With recorded service histories spanning over 60 years, CPVC has shown its durability—with several formulations having improved over time. Its inherent and proven resistance to water disinfectants and chlorine means it will not slowly break down or become brittle, even in systems with aggressive or high mineral water chemistry. CPVC piping is also non-porous and smooth, making it significantly less susceptible to biofilm formation, which helps maintain water quality and flow rates over the system’s lifespan.

- PEX: The lifespan of PEX pipe can be unpredictable. Its vulnerability to hot chlorinated water is well-documented and can lead to premature failure in as little as 10 years. PEX is also a soft material, (hence its flexibility), making it susceptible to damage from over-flexing around corners, punctures from nails, or rodents that can chew through the pipe and cause leaks in hidden areas like walls and crawlspaces.

Water Quality and Safety

The material a pipe is made from should not compromise the quality or safety of the water it carries, especially if the water is intended for consumption.

- CPVC: CPVC ranks among the top most inert piping materials available. It does not leach chemicals into distributed water, and its smooth interior surface resists biofilm formation that can harbor harmful bacteria like Legionella. CPVC pipe and fittings are ASTM and NSF 61 certified safe for potable water.

- PEX: Studies have shown that PEX piping can leach substances into drinking water, including MTBE (a gasoline additive) and toluene. It is also a permeable material, meaning contaminants from outside the pipe can eventually pass through the pipe wall and contaminate the water supply. This is a significant concern if the pipe is installed in areas where it might come into contact with soil contaminants or chemical spills.

Pressure and Flow Rates

Maintaining strong and consistent water pressure is an easy to inspect performance indicator for a plumbing system. The design of the fittings plays a major role in this.

- CPVC: CPVC piping uses socket style fittings where the pipe inserts into the fitting. This "full-bore" design maintains the internal diameter throughout the system to achieve minimal pressure drop and strong, consistent flow rates at every fixture.

- PEX: PEX systems use insert fittings that go inside the pipe. This design significantly reduces the internal diameter at every connection point—by as much as 35% for a 1/2” pipe. The result is a substantial pressure drop and restricted flow, which often requires installers to upsize the pipes to compensate, adding to the total material cost.

UV and Environmental Resistance

Piping materials are often exposed to sunlight during transport, storage, and installation. During this time, the UV resistance of the pipe becomes an important factor.

- CPVC: Most professional grade CPVC pipe is resistant to ultraviolet radiation. While prolonged exposure may cause some discoloration on the pipe's exterior, it does not affect its pressure bearing capability or service life.

- PEX: PEX pipe is considered highly vulnerable to UV damage. The UV rays from sunlight rapidly deplete the antioxidants that protect the pipe from chlorine, which leads to an accelerated breakdown when put into service. Manufacturers' guidelines often state that PEX should not be exposed to sunlight for more than 30 days, as even such short term exposure can lead to the effects that can cause premature failure. This concern makes the proper handling, storage, and timely installation of PEX an important consideration.

|

Pros and Cons of CPVC and PEXWhen making a choice between piping materials, it’s essential to have a balanced view of their strengths and weaknesses. While both CPVC and PEX have their advantages, their respective limitations can have real world consequences on a plumbing system's lasting term health and performance. |

Pros and Cons of CPVC and PEX

When making a choice between piping materials, it’s essential to have a balanced view of their strengths and weaknesses. While both CPVC and PEX have their advantages, their respective limitations can have real world consequences on a plumbing system's lasting term health and performance.

CPVC: The Reliable Standard

CPVC pipe's long standing reputation is built on a foundation of proven durability and safety—it stands up against academic research and maintains its nationwide approval in building standards. Its advantages often make it the wiser choice for projects where lasting reliability is high priority.

Pros:

- Superior Chlorine Resistance: CPVC is naturally immune to damaging effects from chlorine and chloramine, the disinfectants frequently used in public water systems. This ensures the pipe maintains its structural strength for these applications.

- Proven Durability and Lifespan: With a successful track record of over 60 years, CPVC has demonstrated its ability to perform reliably decade after decade with limited risk of the premature failure seen in other materials.

- Maintains Water Quality: CPVC is an inert material that does not leach chemicals when handling water, cold or hot. Its smooth interior surface resists harmful bacterial growth, protecting the water supply.

- Overall Cost Effectiveness: Even though installation may take slightly longer, CPVC systems often result in a lower total cost. The tools and fittings are inexpensive, and its long lifespan without the need for repairs makes CPVC a financially sound investment.

Cons:

- Rigidity: CPVC is a rigid pipe, which means it cannot be bent around corners like PEX. Due to this, elbow fittings and others must be used for directional changes, which can add to the installation time compared to flexible pipe.

- Longer Installation Time: The solvent welding process requires a curing period before the system can be pressurized. This can extend project timelines slightly compared to the instant mechanical connections of PEX.

- Performance in Seismic Zones: Due to its rigidity, CPVC may be more susceptible to cracking during significant seismic events compared to flexible piping, a possible consideration in earthquake-prone regions.

PEX: The Flexible Contender

PEX pipe is often favored for its flexibility and the speed at which it can be installed, particularly in retrofit projects. However, these conveniences come with some noteworthy trade-offs in durability and safety.

Pros:

- Fast, Flexible Installation: PEX can be snaked through walls and bent around obstacles, reducing the number of fittings needed. The mechanical crimp or expansion connections are fast and do not require cure times, speeding up installation.

- Cost Effective for Retrofits: PEX pipe is an attractive option for repiping older homes due to its ability to be pulled through existing wall cavities without extensive demolition.

Cons:

- Vulnerability to UV Degradation: PEX is highly susceptible to sunlight damage. Even short term exposure (30 days) can deplete the protective antioxidants that prevent chlorine degradation; dependent on pipe manufacturer and quality.

- Leaching and Permeability: PEX has been shown to leach chemicals into drinking water and is permeable, meaning contaminants from outside the pipe can enter the water supply.

- Requires Specialized Tools: Installing PEX properly requires specific crimping or expansion tools, which can be an additional upfront cost.

- Reduced Flow Rates: The insert style fittings used in PEX systems obstruct the flow path, causing pressure drop, which often requires larger pipe sizes to compensate.

Ideal Applications and Use Cases

Choosing the right pipe depends on the demands of your specific project. CPVC is best suited for hot water distribution, industrial or commercial systems, and applications where water quality and chemical resistance are priorities—such as facilities with high chlorine levels or strict sanitation requirements.

PEX, on the other hand, is an option for residential retrofits where flexibility is highly beneficial, radiant floor heating, or new builds where installation speed outweighs long term concerns. Each material brings unique strengths, so match your choice to the environment and expected system demands.

Addressing Common Misconceptions

When it comes to plumbing, misinformation can lead to costly mistakes. It's important to separate myths from proven facts to understand the true performance and risks associated with both CPVC and PEX piping.

Debunking Myths About CPVC

Despite its 60 year history of success, a few misconceptions about CPVC persist. Let's set the record straight.

Myth: CPVC is brittle and cracks easily.

This is one of the most common but misleading claims. When installed correctly, CPVC is an incredibly durable material designed to last for decades. Issues of brittleness or cracking almost always stem from improper installation practices, such as failing to allow room for thermal expansion, using the wrong tools or wrong primer/cement, or rough handling in cold weather. Professional installation according to manufacturer guidelines can ensure a robust, lasting system.

Myth: CPVC installation is complex and slow.

While the solvent welding process for CPVC requires a short curing period, it is far from complex. The technique uses simple, inexpensive hand tools and creates a permanent, one-piece joint that is stronger than the pipe itself. In contrast, PEX requires specialized tools that must be calibrated correctly to avoid bad connections. Many contractors find the straightforward nature of solvent welding to be highly reliable and easy to teach to new technicians.

Highlighting the Hidden Risks of PEX

While often marketed as a simple and fast solution, PEX comes with several hidden risks and costs that are not always apparent.

Hidden Cost: Specialized and Expensive Tools.

PEX cannot be installed with basic hand tools or with pipe cement that provides everything you need. It requires an investment in proprietary crimping or expansion tools, which can cost hundreds or even thousands of dollars for professional grade tools. These tools also need regular calibration to ensure the connections are secure, adding another layer of maintenance and potential for error.

Hidden Risk: Chlorine Degradation and System Failure.

The most significant risk associated with PEX is its vulnerability to the chlorine used in municipal water supplies and chlorine’s associated derivatives. Unlike CPVC, which is immune to chlorine, PEX relies on a limited supply of antioxidants to protect it. Hot water accelerates the depletion of these antioxidants that, when gone, can lead to micro-cracks, pinhole leaks, and eventual system failure. This has been the subject of numerous class action lawsuits, leaving homeowners with extensive water damage and the need for a complete system repipe.

Hidden Risk: Water Contamination.

PEX is a permeable material, which means that contaminants from the surrounding environment can pass through the pipe wall and into the drinking water. This is a serious concern if the pipe is installed in areas with contaminated soil or near chemical storage areas; (albeit, not a major concern for most residential applications). Studies have also documented that low quality PEX pipe can leach chemicals like MTBE and toluene into the water, which correctly has raised health and safety concerns.

|

Regulatory and Warranty ConsiderationsIn the United States, plumbing materials must meet strict regulatory standards and are often backed by manufacturer warranties. However, not all certifications and warranties are created equal, and the finer details can reveal a lot about a material's true reliability. |

Regulatory and Warranty Considerations

In the United States, plumbing materials must meet strict regulatory standards and are often backed by manufacturer warranties. However, not all certifications and warranties are created equal, and the finer details can reveal a lot about a material's true reliability.

Certifications and Compliance

Both CPVC and PEX must be certified for use with potable water. The primary certification in North America is NSF/ANSI/CAN 61, which ensures that the material does not contribute harmful contaminants to drinking water.

- CPVC: CPVC is certified to NSF 61 under all water conditions. Its inert nature means it consistently meets safety standards regardless of water temperature or chemical composition. This provides peace of mind that the material will not compromise water quality over its service life.

- PEX: While PEX is also certified to NSF 61, its performance can be conditional. The material's tendency to leach chemicals can be influenced by water chemistry and temperature. The bigger issue, however, is its performance under real world water treatment conditions. PEX is not rated to withstand chlorinated water at the same high temperatures as CPVC, a critical detail often buried in technical documents.

Warranty Coverage and Exclusions

A manufacturer's warranty should be a promise of quality and reliability. However, many PEX warranties contain certain exclusions that can render them void precisely when a failure occurs.

- CPVC Warranties: Reputable CPVC manufacturers typically offer strong warranties that stand behind the product's performance. Because CPVC is inherently resistant to chlorine and other water treatment chemicals, these warranties are not invalidated by aggressive water conditions. This reflects the manufacturer's confidence in the material's long term durability given the piping is properly installed.

- PEX Warranties: The Water Quality Exclusion. A major red flag for PEX pipe is the common addition of a "water quality exclusion" in its warranties. This clause often states that the warranty does not cover damage caused by "unusual" or "aggressive" water conditions, which can include the very levels of chlorine and high temperatures found in standard municipal and residential hot water systems. This means that if a PEX pipe fails due to chlorine degradation—its most well known vulnerability—the warranty may not cover the damage or the cost of replacement. This effectively shifts the risk of material failure from the manufacturer to the contractor and homeowner. However, it is worth noting that not all PEX manufacturers include such exclusions, so it is important to review warranty terms carefully.

Choosing the Right Material for Your Project

Selecting the appropriate plumbing material is a decision that extends far beyond the construction phase. It impacts long term performance, maintenance costs, and the health of the building's occupants. To make the best choice, it's essential to weigh several key factors against the strengths and weaknesses of each material.

Factors to Consider

- Budget: While it's tempting to focus solely on the upfront price of materials, a true cost analysis includes tools, fittings, labor, and potential future replacement. PEX may seem cheaper per foot, but its specialized tools and fittings often erase that initial advantage. CPVC's use of inexpensive fittings and simple hand tools, combined with its longer lifespan, frequently results in a lower total cost of ownership.

- Installation Environment: Consider where the pipes will be installed. PEX's high vulnerability to UV radiation makes it a poor choice for any application involving sunlight exposure, even for several weeks during the construction phase. CPVC is not affected by UV light in the same way, making it a much more forgiving and durable material for a wide range of job site conditions, both indoors and outdoors.

- Water Quality and Treatment: This is one of the most critical points. Most municipal water in North America is treated with chlorine or chloramine. PEX is known to progressively degrade when exposed to hot, chlorinated water, which can lead to system failure. CPVC is immune to this type of chemical damage, making it a reliable choice for systems connected to public water supplies.

- Long Term Maintenance and Durability Needs: A plumbing system should be a "set it and forget it" installation. CPVC's proven 60 year track record provides confidence in its long term durability. In contrast, PEX's history of class action lawsuits related to material failure, its susceptibility to rodent damage, and its chemical vulnerabilities present significant long term risks that can lead to costly repairs and property damage.

Recommendations for Specific Scenarios

- Residential Homes: For any home connected to a municipal water supply, CPVC is the safer, more reliable option. Its resistance to chlorine ensures a long service life for both hot and cold water lines, and its inert nature protects drinking water quality.

- Industrial and Commercial Buildings: In these demanding environments, there is no substitute for CPVC. Its ability to handle higher pressures, temperatures, and a wide range of chemicals makes it the industry standard for process piping, water treatment facilities, and large scale plumbing systems where failure is not an option.

- Retrofitting Projects: While PEX is often promoted for its flexibility in retrofits, CPVC remains a strong contender. For projects requiring lasting reliability and guaranteed water quality, the extra effort to install rigid CPVC pipe is a worthwhile investment.

Why CPVC Outperforms PEX

When all factors are considered, CPVC consistently emerges as the superior choice for plumbing systems that demand performance, safety, and longevity. The evidence lies in its proven history, robust material properties, and manufacturer support.

- Proven Track Record: CPVC isn't a new or experimental material. It has been successfully used in plumbing systems for over 60 years, providing decades of reliable, leak free service in millions of homes and businesses. This long history stands in stark contrast to PEX, which has been plagued by product liability issues and failures related to its inability to withstand common water conditions.

- Water Quality Assurance: Your plumbing system should protect, not compromise, the water it carries. CPVC is one of the most inert and stable materials available, ensuring it will not leach harmful chemicals into the water. It is fully compliant with NSF 61 standards under all conditions and its smooth surface resists the growth of potentially dangerous biofilms.

- Unmatched Chlorine Resistance: The single greatest threat to many plumbing materials is the disinfectant used to keep our water safe. CPVC’s molecular structure makes it naturally immune to chlorine and chloramine. This means its strength and durability are unaffected by treated water so it won't become brittle or develop micro-cracks over time.

- Superior Warranty Coverage: A warranty is a reflection of a manufacturer’s confidence in its product. Reputable CPVC manufacturers offer comprehensive warranties that are not voided by water chemistry. This is a critical distinction from PEX, whose warranties often contain "water quality exclusions" that can leave contractors and homeowners unprotected if the system fails due to chlorine degradation.

|

The Clear Choice for ReliabilityChoosing between CPVC and PEX is a choice between a proven, reliable standard and a material with several, well documented risks. While PEX’s flexibility may offer some initial installation convenience, in many cases this benefit is outweighed by its vulnerabilities to chlorine, punctures, tears, UV light, and chemical permeation. These weaknesses can affect the plumbing system’s long term integrity and create risks of leaks, water damage, and contamination. CPVC pipe, on the other hand, delivers on every critical metric. Its resistance to chemical damage, its proven service life, and its commitment to water purity make CPVC the more dependable choice for modern plumbing. For projects that demand reliability, safety, and true long term cost effectiveness, CPVC is the clear and responsible choice. Don’t leave your project’s success to chance. Explore the selection of professional quality CPVC pipes and fittings available from PVC Pipe Supplies. Made in the USA by America’s top manufacturers using top-of-the-line Corzan CPVC material. Our team of experts is ready to help you select the right materials to build a durable, long lasting plumbing system you can trust. Contractors with large orders? Fill out our contractor form to see if you qualify for our bulk order discount today. |

Don’t leave your project’s success to chance. Explore the selection of professional quality CPVC pipes and fittings available from PVC Pipe Supplies. Made in the USA by America’s top manufacturers using top-of-the-line Corzan CPVC material. Our team of experts is ready to help you select the right materials to build a durable, long lasting plumbing system you can trust. Contractors with large orders? Fill out our contractor form to see if you qualify for our bulk order discount today.