|

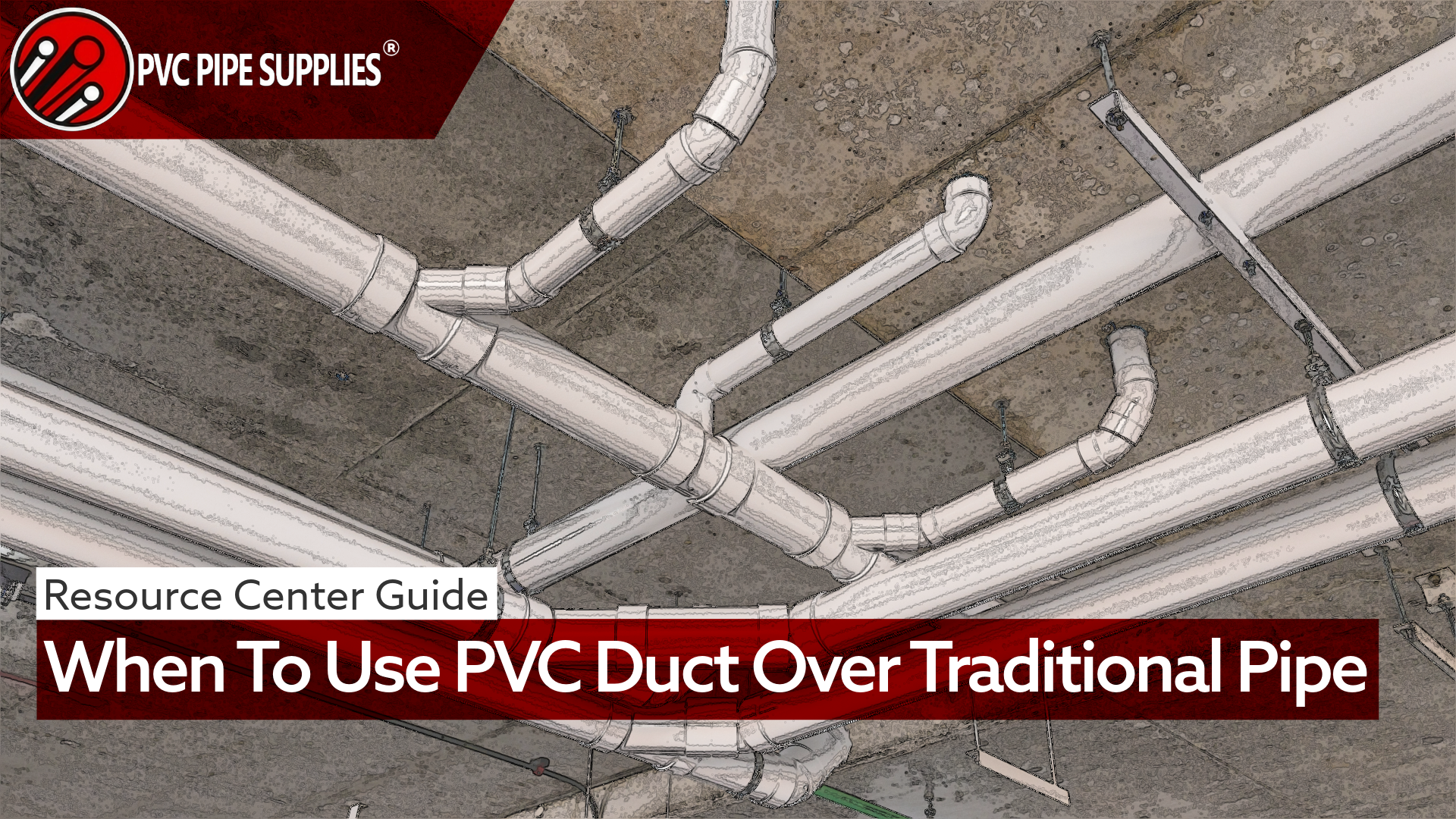

When planning a project that involves moving air, fumes, or light drainage, choosing the right plumbing and material types is essential for a successful and long lasting setup. While traditional pipe, often made of metal or standard PVC, is a common choice for many applications, PVC duct offers a specialized alternative with distinct advantages for ductwork systems. This article will guide you through the specific scenarios where PVC duct is not just a viable option, but the better one. We will explore its unique properties, benefits, and limitations to help you determine when to use PVC duct over traditional pipe. |

When planning a project that involves moving air, fumes, or light drainage, choosing the right plumbing and material types is essential for a successful and long lasting setup. While traditional pipe, often made of metal or standard PVC, is a common choice for many applications, PVC duct offers a specialized alternative with distinct advantages for ductwork systems.

This article will guide you through the specific scenarios where PVC duct is not just a viable option, but the better one. We will explore its unique properties, benefits, and limitations to help you determine when to use PVC duct over traditional pipe.

What is PVC Duct?

PVC duct is a specialized type of piping made from polyvinyl chloride, the same versatile material used for standard PVC pipe. However, it is engineered for different purposes. Its primary role is in applications involving air movement, such as ventilation, fume and exhaust systems, and light drainage. Unlike traditional PVC pipe, which is built to handle pressurized liquids, PVC duct is designed exclusively for non-pressurized or low-pressure situations.

The most significant difference from standard PVC pipe lies in its construction. PVC ductwork features thinner walls compared to its standard PVC pipe counterparts. This design choice makes it lighter and less expensive, which is ideal for overhead or complex installations where weight and total costs play a significant role. Despite its thinner walls, it retains many of PVC's most valued qualities, including its chemical and corrosion resistance. This makes PVC duct pipe an excellent material for safely venting corrosive fumes and moist air that would quickly degrade metal alternatives.

Advantages of PVC Duct Over Traditional Pipe

When reviewing different materials for your project, PVC duct presents several clear advantages over traditional piping, particularly metal. These benefits make it an ideal selection for projects where durability, cost, and ease of use are priorities.

Lasting Corrosion Resistance

One of the most significant benefits of PVC duct is its natural resistance to corrosion. Unlike metal pipes that rust and degrade when exposed to moisture, chemicals, or salty air, PVC remains largely unaffected. This quality makes it a long lasting solution for exhaust systems in humid climates or industrial settings where various fumes are present. PVC ductwork can be installed without worrying about the eventual degradation that affects metal alternatives.

Lightweight and Easy to Install

PVC duct is considerably lighter than metal piping, which dramatically simplifies transportation and installation. Its reduced weight means it is easier to handle on-site and often requires less substantial support structures for overhead applications. This allows for quicker installation, reducing labor costs and project timelines.

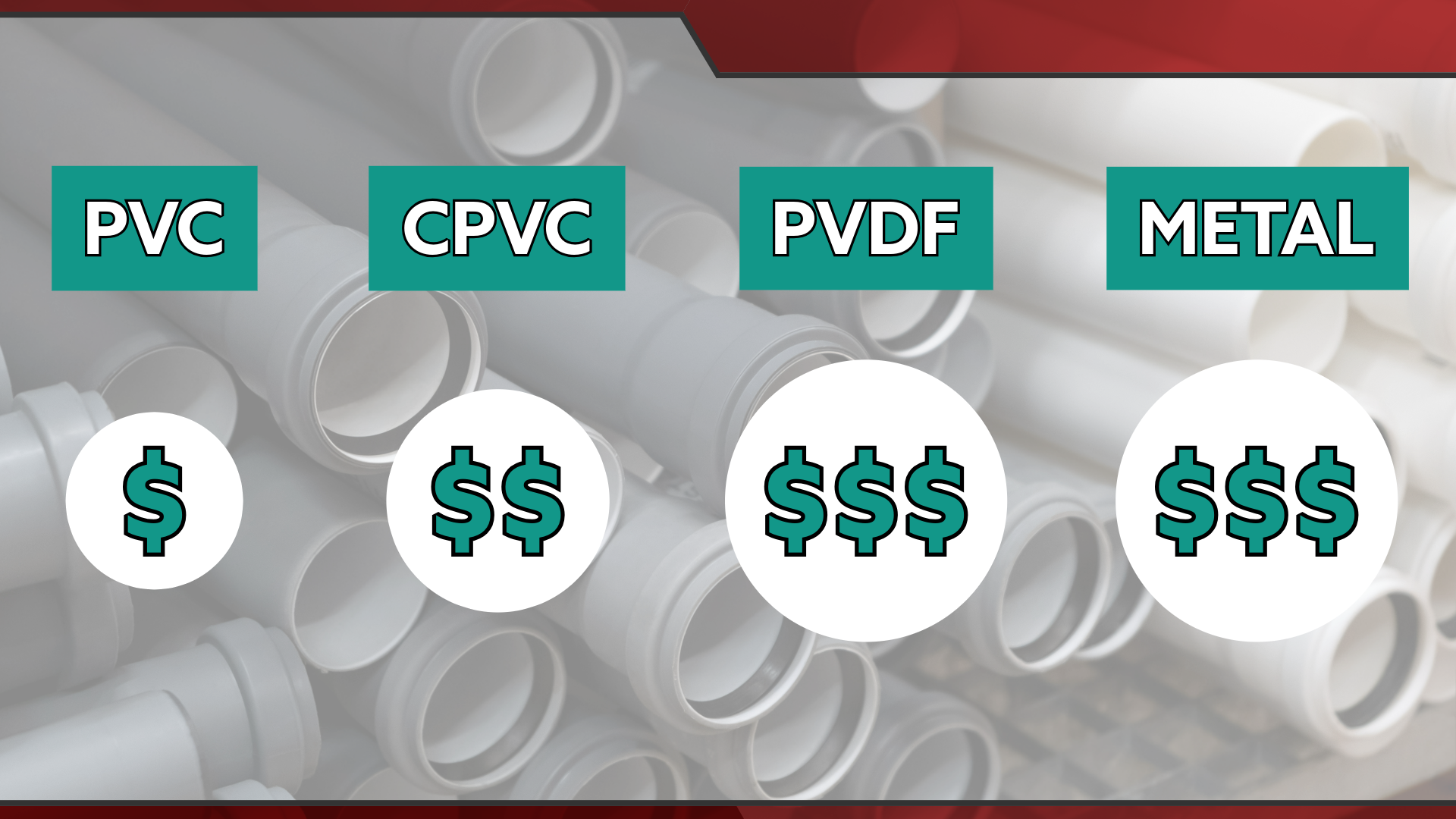

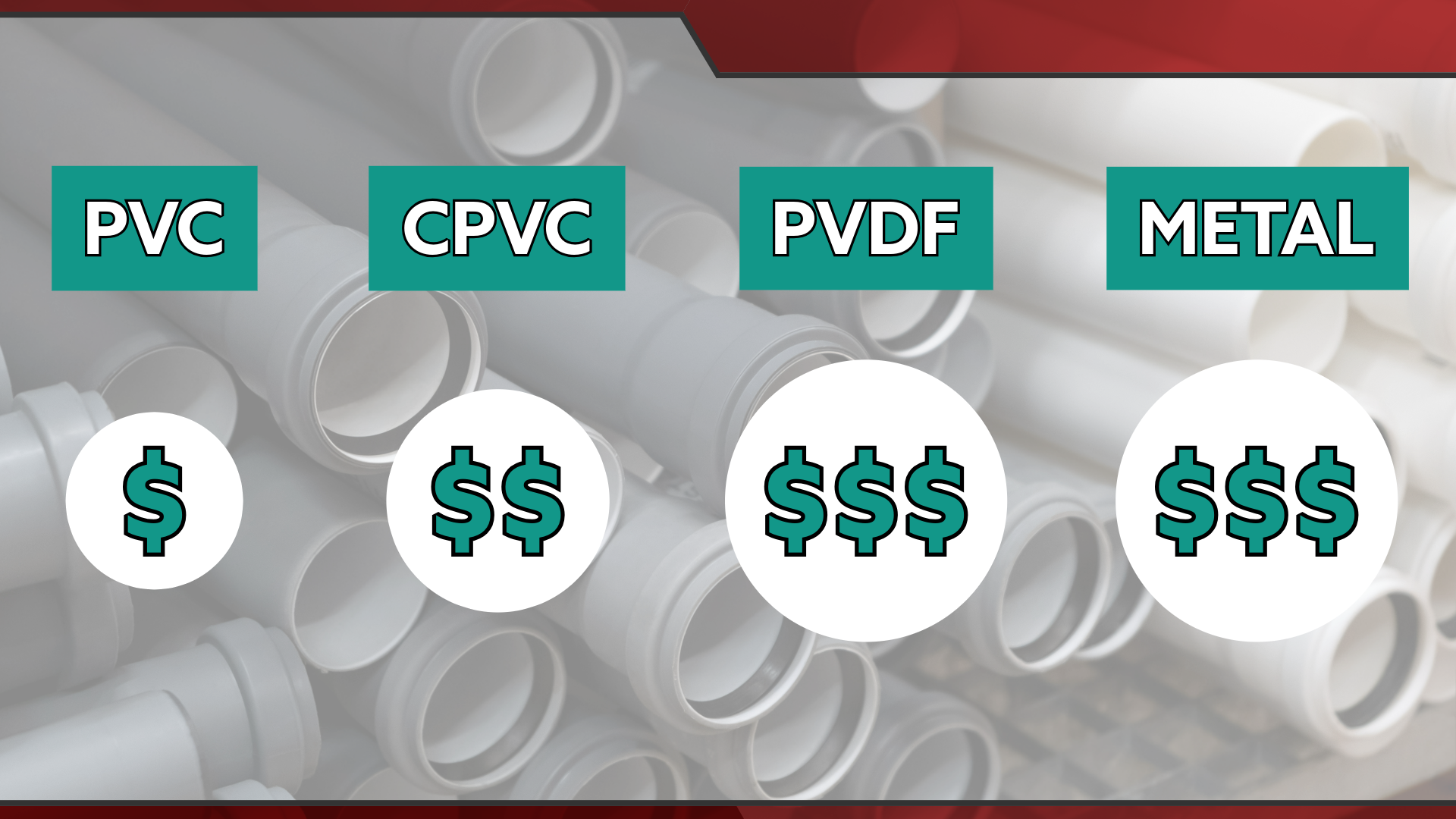

Superior Cost Effectiveness

Projects often come down to budget, and PVC duct is a highly economical choice. Both the raw materials and the installation process are typically less expensive than those for metal ductwork. The combination of lower material costs, labor time, and long term maintenance makes PVC duct a smart decision financially for many ventilation and exhaust projects.

Excellent Chemical Resistance

In environments where chemical fumes or vapors are present, material choice is a matter of safety and system integrity. PVC duct is resistant to a wide range of acids, bases, and other chemicals, allowing it to safely transport toxic or corrosive gases without risk of significant breakdown. This makes PVC duct an essential component of laboratory hoods, industrial ventilation, and chemical processing facilities.

Effective Thermal Insulation

Compared to metal, PVC is a better insulator. Metal ductwork tends to disperse heat or cold, leading to energy loss as air travels through the system. PVC duct helps maintain the temperature of the air it carries, which in turn contributes to greater system efficiency and reduces the need for additional insulation in many applications.

Simple Onsite Customization

PVC duct systems can be easily adapted to fit the unique requirements of any space. The pipes can be cut to length and joined with a variety of fittings onsite using simple tools. This flexibility allows you to create fully customized layouts that navigate around obstacles and meet precise design specifications, a task that is far more complex and costly with rigid metal ductwork.

Limitations of PVC Duct

While PVC duct offers many advantages, it is not a universal solution. Understanding its limitations will ensure the safety, efficiency, and longevity of your ductwork system. In certain situations, the properties of other duct materials may make them the more appropriate choice.

Temperature Constraints

Perhaps the most significant limitation of standard PVC duct is its relatively low heat tolerance, particularly compared to metal ductwork. PVC is designed for applications where temperatures will not exceed 140°F (60°C). Exposure to higher temperatures can cause the material to warp, soften, or become brittle, leading to cracks and system failure. For applications involving high heat exhaust, such as from certain types of furnaces, boilers, or commercial kitchen vents, heat resistant materials like metal or CPVC (which can handle temperatures up to 200°F) are necessary.

Structural and Support Considerations

Although its lightweight nature is a benefit for installation, it can be a drawback in certain structural scenarios. PVC duct is less rigid than metal and may sag over long spans if not properly supported. Overhead installations, in particular, often require more frequent supports compared to metal ductwork to prevent such sagging and maintain proper alignment. In applications where the ductwork must bear a mechanical load or withstand significant vibration, metal is often the more durable option.

Sensitivity to UV Radiation

When used outdoors, standard PVC duct is susceptible to damage from prolonged exposure to ultraviolet (UV) radiation from the sun. Over time, sunlight can break down the PVC material, causing it to lose strength and become brittle. This can affect the integrity of the duct and lead to premature failure. If outdoor installation is unavoidable, it is essential to use a UV resistant grade of PVC, paint the duct with a light colored, UV blocking paint, or otherwise shield it from direct sunlight.

Unsuitable for Pressurized Liquids

It is important to remember that PVC duct is designed specifically for non-pressurized or very low pressure airflow. Its walls are not engineered to withstand the pressure from transporting liquids in plumbing or irrigation systems. Attempting to use PVC duct for pressurized applications will inevitably lead to leaks, bursts, and complete system failure. For any application involving pressurized liquids, you must use standard schedule 40 or 80 PVC pipe.

Best Applications for PVC Duct

Understanding the unique advantages and limitations of PVC duct will let you identify the best scenarios for its use. Its combination of corrosion resistance, lightweight design, and low cost makes PVC duct the superior choice for the following applications.

Residential and Commercial Exhaust Systems

PVC duct is an excellent material for general purpose exhaust systems in both homes and businesses. This includes venting air from bathrooms, kitchens (for non-grease-producing fans), clothes dryers (where permitted by local codes), and other applications that require the release of some kind of exhaust. PVC duct’s smooth interior surface promotes airflow, while its moisture resistance ensures it will not rust or be damaged from humid air being expelled. Its ease of installation also makes PVC duct a practical choice for routing ductwork through tight spaces like attics and crawlspaces.

Chemical and Fume Ventilation

In environments with corrosive fumes, PVC duct is often the best and safest option. Examples include laboratories, manufacturing facilities, workshops, and indoor grow facilities. Unlike metal, which can be quickly damaged by chemical vapors, PVC is non-reactive to a wide range of acids, bases, and solvents. This ensures the long term strength of the ventilation system to safely direct hazardous fumes away from occupied areas.

Moisture Exposed Installations

For any installation where moisture and humidity are constant, PVC duct is an ideal choice over metal. This is particularly true for ductwork that needs to be run underground, embedded within concrete slabs, or near the ocean, where salty air and high humidity are present. Metal would quickly corrode and fail in these environments, but PVC’s waterproof and rustproof nature allows it to provide decades of reliable service. It can handle ground moisture and condensation without any risk of deterioration.

HVAC Systems for Specific Functions

While PVC duct is not suitable for high heat HVAC applications, it serves two functions exceptionally well. First, it is the standard material for condensate drainage lines in air conditioning and high efficiency furnace systems. Its moisture resistance and low cost make it perfect for safely channeling condensation away from units. Second, it can be used for low temperature, low pressure air distribution, such as in fresh air intake or certain ventilation recovery systems where the air temperature remains well below the 140°F threshold.

When to Choose Pipes Other than PVC Duct

Recognizing the limitations of PVC duct is just as important as knowing its strengths. In several scenarios, other pipe materials like metal or CPVC are not only a better choice but necessary to ensure the system operates safely. Choosing these other pipe types is essential in projects with performance demands and characteristics that PVC duct cannot match.

High Temperature Applications

For any system that transports hot air or gases, other materials are the only safe option. PVC duct should not be used in environments exceeding 140°F, which rules it out for venting high efficiency furnaces, boilers, water heaters, and commercial kitchen equipment. In these cases, metal ductwork (such as galvanized steel or aluminum) or CPVC duct pipe, which can withstand higher temperatures, is required to prevent failure, warping, or the release of harmful fumes.

Pressurized Systems

Traditional piping is designed to handle pressure, whereas PVC duct is not. Any application that involves moving liquids under pressure, such as plumbing supply lines and irrigation systems, will require the structural strength of materials like standard PVC pipe (Schedule 40 or 80), copper, or PEX. Using thin walled PVC duct for these jobs would likely result in rapid leaks and system blowouts.

When Sound Insulation is a Priority

Air moving through ductwork can generate noise, which can be a concern in some residential and office environments. Metal ductwork is generally more rigid and less prone to vibration than PVC duct, which often results in quieter operation. While sound can be managed in PVC systems with proper insulation and dampeners, metal ductwork generally provides better acoustic performance, and in turn, makes it preferable when noise minimization is the goal.

Ductwork Takeaway

Choosing between PVC duct and traditional pipe, such as metal and standard PVC pipe, is a decision that can directly impact the performance and lifespan of your ductwork system. PVC duct is the superior choice for non-pressurized, low heat uses in applications that benefit from its exceptional corrosion resistance, light weight, and low cost. For exhaust systems, chemical fume ventilation, and moisture exposed work conditions, PVC duct provides a durable and reliable solution that often outperforms metal alternatives. Making a knowledgeable choice will ensure your system is not only built efficiently but built to last.

Get the Best Materials for Your Project

Understanding the difference between PVC duct and traditional pipe is the first step. The next is sourcing high quality materials at a competitive price. Whether you are tackling a small home repair or managing a large commercial installation, material costs can significantly impact your budget.

If you are a contractor bidding on a job or a professional planning a major project, getting the best value on materials is essential for staying competitive and profitable. This is why PVC Pipe Supplies offers contractor pricing and bulk discounts to support your business. Our team is ready to provide you with a custom quote, ensuring you get the right materials at the best possible price. Explore our selection of PVC duct and duct fittings today.