|

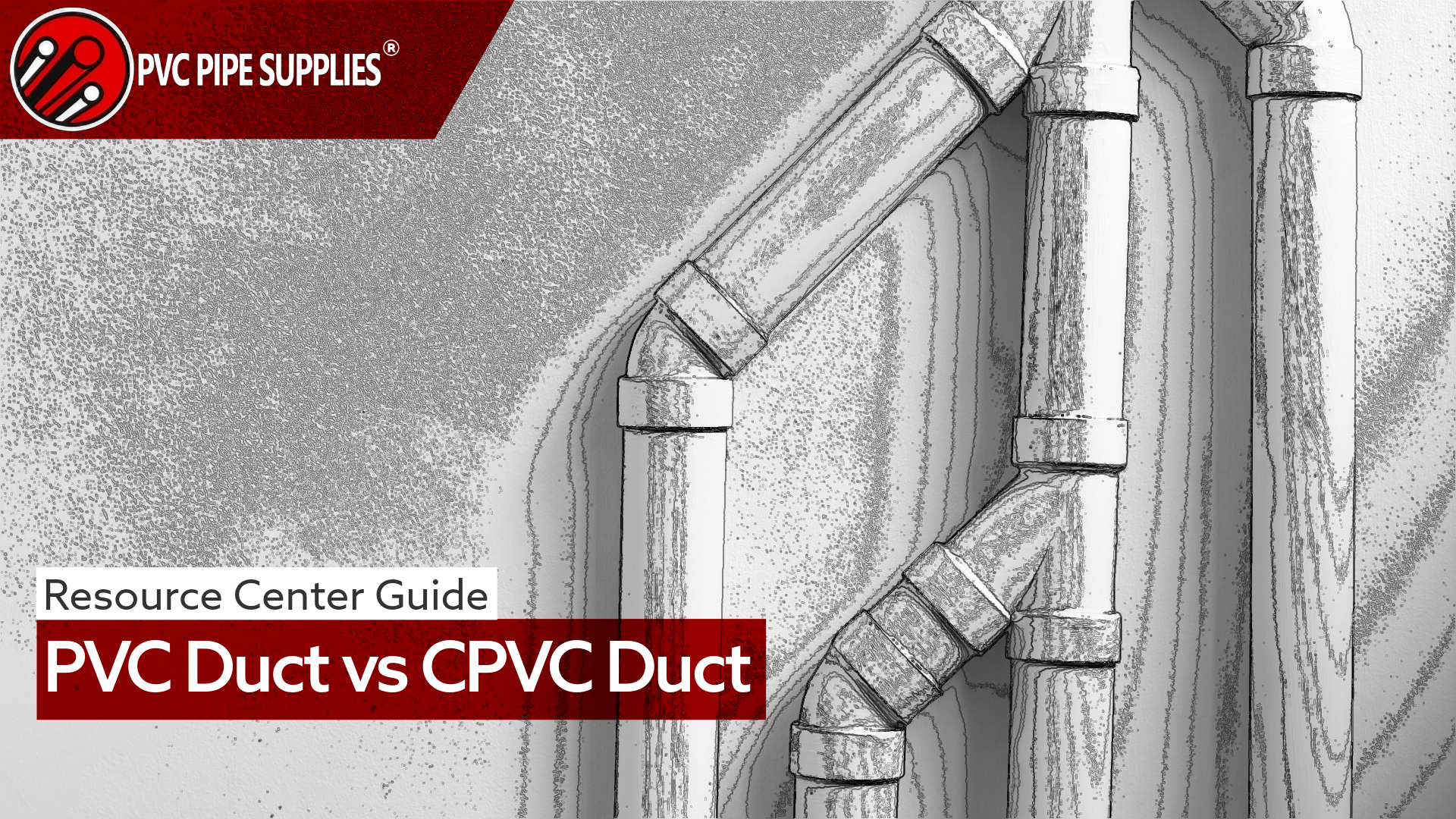

Comparing Features, Specs, and UsesChoosing the right material for industrial ductwork is a decision that can impact system lifespan, safety, and your bottom line. An incorrect choice can lead to premature failure, downtime, more upfront costs, and potential safety hazards. For system designers and contractors, understanding the differences between duct materials isn't just helpful—it's essential for a successful project. The most common non-metallic options are PVC and CPVC ducts. These two options stand out for their reliability, performance, and lower price compared to metal duct. While the two may appear similar, their individual properties make them suitable for different applications. Here, we’ll compare PVC vs CPVC duct, breaking down their features, specifications, and ideal uses to help you make the best choice for your next project. |

Comparing Features, Specs, and Uses

Choosing the right material for industrial ductwork is a decision that can impact system lifespan, safety, and your bottom line. An incorrect choice can lead to premature failure, downtime, more upfront costs, and potential safety hazards. For system designers and contractors, understanding the differences between duct materials isn't just helpful—it's essential for a successful project.

The most common non-metallic options are PVC and CPVC ducts. These two options stand out for their reliability, performance, and lower price compared to metal duct. While the two may appear similar, their individual properties make them suitable for different applications. Here, we’ll compare PVC vs CPVC duct, breaking down their features, specifications, and ideal uses to help you make the best choice for your next project.

What Are PVC and CPVC Ducts?

PVC (Polyvinyl Chloride) and CPVC (Chlorinated Polyvinyl Chloride) are two thermoplastics known for their durability and corrosion resistance. Both serve as lightweight, cost friendly alternatives to traditional metal ductwork, which can be susceptible to rust and chemical damage.

The primary difference between the two lies in their chemical makeup, similar to how stainless steel is different from galvanized steel. CPVC is essentially PVC that has undergone an additional chlorination process. This extra step enhances the material's properties to create a more robust polymer with superior strength and higher temperature resistance. While both materials offer excellent performance, these distinctions determine where each one excels.

Key Differences Between PVC and CPVC Ducts

When selecting between PVC and CPVC, it is important to evaluate how their properties align with your application's specific demands.

Temperature Tolerance

One main difference is their maximum temperature tolerance.

- PVC Duct: Has a maximum operating temperature of 140°F (60°C). Ideal for standard ventilation and exhaust systems where temperatures remain moderate.

- CPVC Duct: Has a maximum operating temperature of 200°F (93°C). This higher thermal resistance makes it suitable for applications involving hot exhaust, steam, or high temperature fumes.

Chemical Resistance

Both materials are highly resistant to a broad spectrum of chemicals, acids, and alkalis. However, the added chlorine in CPVC duct gives it an advantage in more aggressive environments. CPVC provides superior resistance to a wider range of corrosive gases and acids, making it a more reliable option for chemical processing plants, laboratories, and facilities handling potentially hazardous materials.

Fire and Smoke Safety

In environments where fire safety is a concern, CPVC is the superior choice.

- CPVC Duct: Typically meets higher fire safety standards, including UL 94 V-0, which means it self extinguishes when the flame source is removed and produces very little smoke. This makes it suitable for use in air plenums and high occupancy buildings.

- PVC Duct: Is more likely to burn once ignited and can produce thick, hazardous smoke, limiting its use in applications with stringent fire codes.

Cost

Budget is a factor in any project. PVC duct is generally more affordable than CPVC, making it a more price friendly option for applications where its performance characteristics allow its use. While CPVC has a higher upfront cost, its better durability and resistance can lead to long term savings by reducing maintenance and replacement needs in certain work environments.

Strength and Stability

CPVC is not only more heat resistant but also more rigid than PVC. It expands and contracts less with temperature fluctuations, which helps maintain the structural strength of long duct runs.

Regulatory Compliance

Building codes and industry standards often require certain material choices. This is especially true in regulated environments like hospitals, pharmaceutical labs, and food processing plants. Due to its superior fire safety ratings and chemical resistance, CPVC is more likely to meet these higher requirements as a safe and compliant choice.

Applications of PVC and CPVC Ducts

Let's look at ideal use cases for each duct material to match performance and cost with safety.

PVC Duct Applications

With its reliable performance and lower price point, PVC duct is well suited for a variety of common applications, including:

- General HVAC Systems: Efficiently moving cool or ambient air in commercial and residential buildings.

- Light Industrial Exhaust: Venting fumes and dust in workshops, garages, and manufacturing facilities where temperatures are not elevated.

- Water and Wastewater Treatment: Handling corrosive fumes from treatment processes that do not involve high heat.

CPVC Duct Applications

CPVC duct is engineered for more demanding conditions where safety and reliability are paramount. Its applications include:

- Chemical Fume Exhaust: Safely venting aggressive fumes in laboratories, chemical manufacturing, and plating facilities.

- High Temperature Ventilation: Managing hot air and steam exhaust from industrial ovens, boilers, and processing equipment.

- Critical Environments: Use in hospitals, pharmaceutical cleanrooms, and food and beverage plants where fire safety and resistance to contamination are non-negotiable.

Installation and Maintenance

Both PVC and CPVC ducts are lightweight. This makes them much easier and faster to install than heavy metal ductwork. The primary joining method of PVC and CPVC duct is solvent welding, which creates a permanent, airtight seal. For large diameter, greater than 14” diameter duct pipe, hot air welding is often the recommended method of joining. For solvent welding between the two duct pipes, CPVC ductwork requires CPVC cement that often has a longer curing time, which can impact project timelines. For overhead installations, PVC and CPVC duct will require pipe hangers or similar vertical support installed at specific distance intervals to prevent sagging or downward stress load that could cause pipe collapse.

In terms of maintenance, both materials are virtually corrosion proof from weather effects, eliminating the need for painting or coating. CPVC’s superior dimensional stability means it requires fewer expansion joints and is less prone to stress related fatigue over time, especially in duct systems with significant temperature swings.

Choosing the Right Material: A Quick Guide

To choose between PVC duct and CPVC duct, consider the following:

- Operating Temperature: If temperatures will exceed 140°F, choose CPVC.

- Chemical Exposure: For highly corrosive fumes, CPVC often offers better long term protection.

- Fire Safety Codes: If your application requires compliance with specific flame and smoke ratings, CPVC is the right choice.

- Budget: For low temperature, non aggressive applications, PVC is the most cost effective solution.

| Scenario | Recommended Material |

| Low temperature air movement | PVC Duct |

| High temperature or steam exhaust | CPVC Duct |

| General purpose, low risk systems | PVC Duct |

| Chemical fume or corrosive gas handling | CPVC Duct |

| Projects with strict fire codes (hospitals, labs) | CPVC Duct |

Find Your Duct Solution at PVC Pipe Supplies

At PVC Pipe Supplies, we offer a comprehensive selection of high quality PVC and CPVC duct pipe from trusted manufacturers like Harrison Machine & Plastic. Our products are engineered to provide reliable, long lasting performance built for successful use across a range of industrial and commercial applications.

We stock PVC duct pipe in sizes ranging from 2" to 24", ideal for your standard HVAC and exhaust needs. For more demanding jobs, our CPVC duct pipe provides superior performance in high heat and corrosive applications. Both options are available in standard lengths, with a full catalog of fittings, and can be easily cut or customized for your project.

Your Partner in Performance

Choosing between PVC and CPVC ductwork comes down to matching the capability of the material with the demands of your application. By understanding temperature, chemical exposure, and specific safety requirements, you can choose the best solution to deliver lasting service and peace of mind.

Explore our full range of PVC duct and CPVC duct to find the perfect fit for your needs. For expert guidance or to request contractor pricing on bulk orders, contact our team today.