|

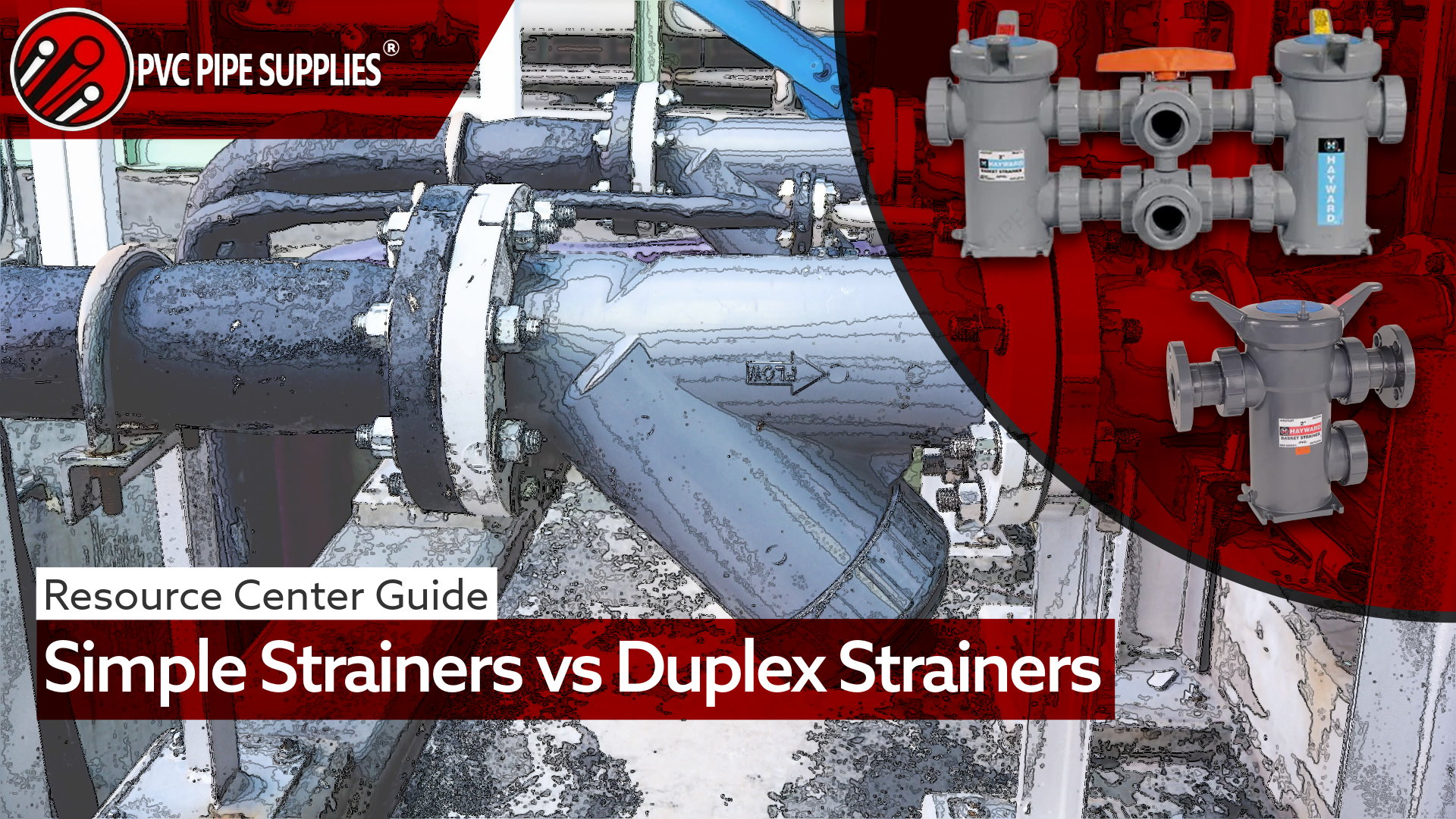

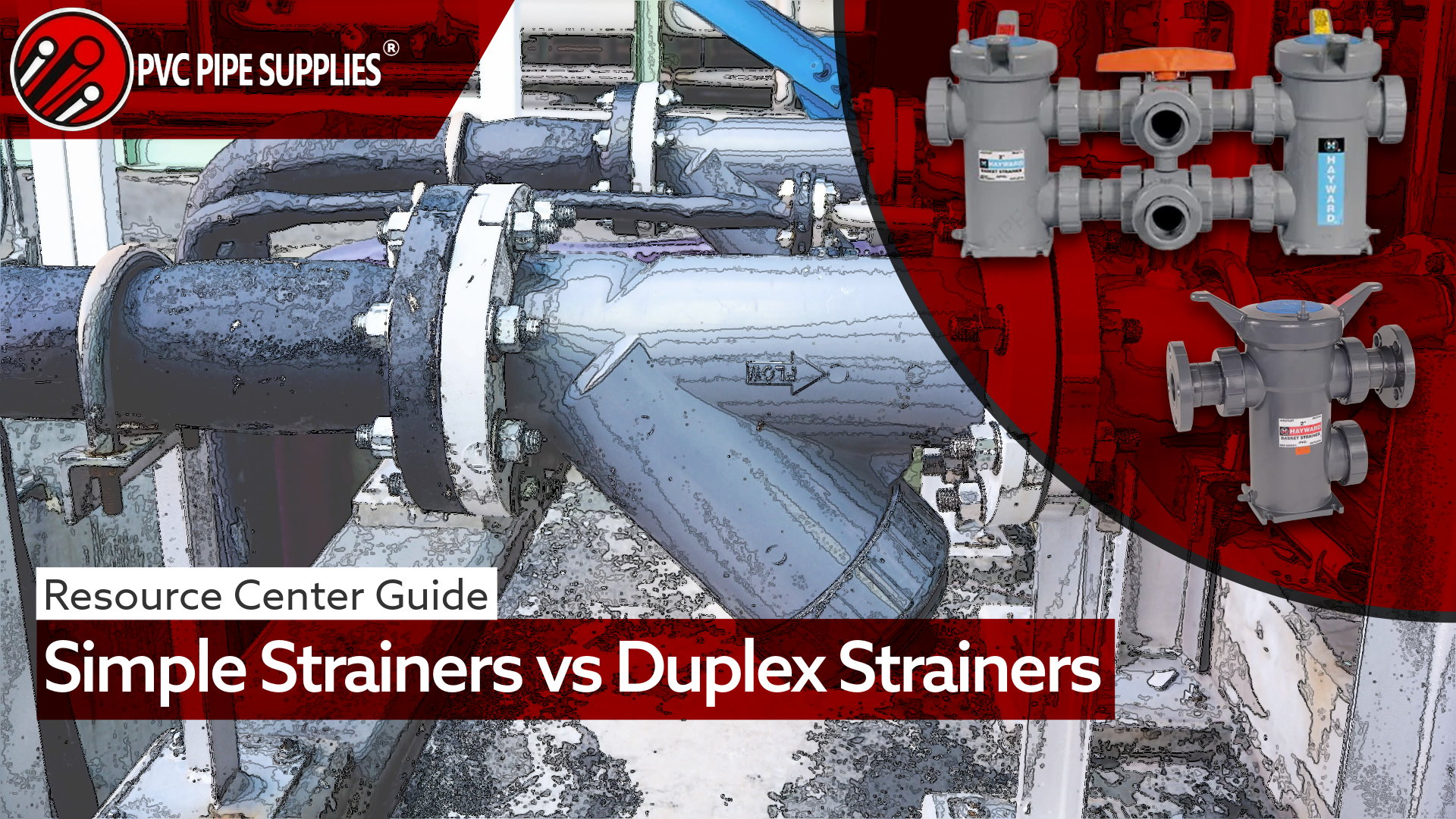

In any pipeline system with valuable equipment, protecting operating equipment from debris is vital to service life and continuity. In plumbing systems, particles or suspended solids can clog nozzles, damage pumps, or contaminate an entire product batch that can lead to costly downtime and repairs. This is where pipeline strainers serve their use. By filtering out unwanted solids, they safeguard your system and maintain the quality and cleanliness of your pipeline fluids. Among the most common strainer types are simplex and duplex strainers. While both serve the same base purpose, they are each designed for different operational needs. Choosing the wrong one can mean either overspending on an unnecessarily complex system or facing more frequent interruptions for maintenance. This guide will compare simplex vs duplex strainers, breaking down their specs, features, and ideal uses. Understanding their key differences will help you buy the right pipe filter for your application. |

In any pipeline system with valuable equipment, protecting operating equipment from debris is vital to service life and continuity. In plumbing systems, particles or suspended solids can clog nozzles, damage pumps, or contaminate an entire product batch that can lead to costly downtime and repairs. This is where pipeline strainers serve their use. By filtering out unwanted solids, they safeguard your system and maintain the quality and cleanliness of your pipeline fluids.

Among the most common strainer types are simplex and duplex strainers. While both serve the same base purpose, they are each designed for different operational needs. Choosing the wrong one can mean either overspending on an unnecessarily complex system or facing more frequent interruptions for maintenance.

This guide will compare simplex vs duplex strainers, breaking down their specs, features, and ideal uses. Understanding their key differences will help you buy the right pipe filter for your application.

What Are Simplex and Duplex Strainers?

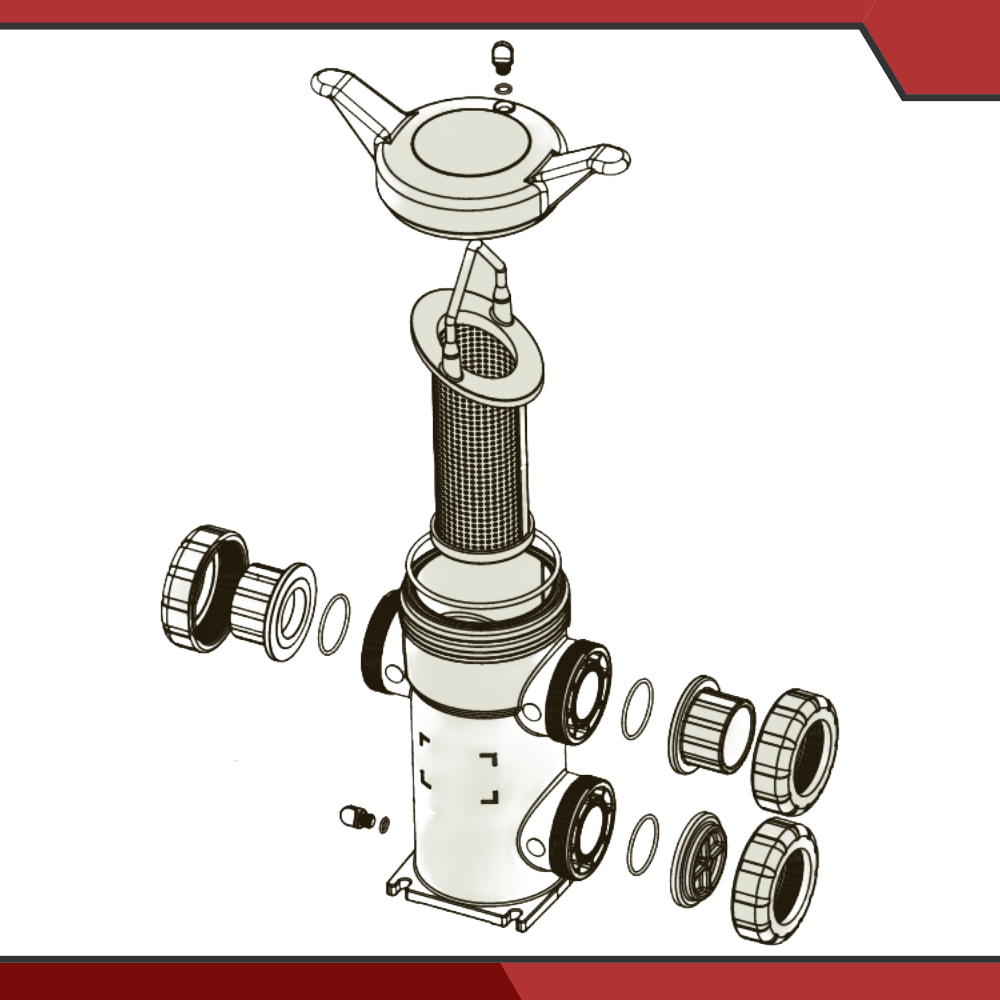

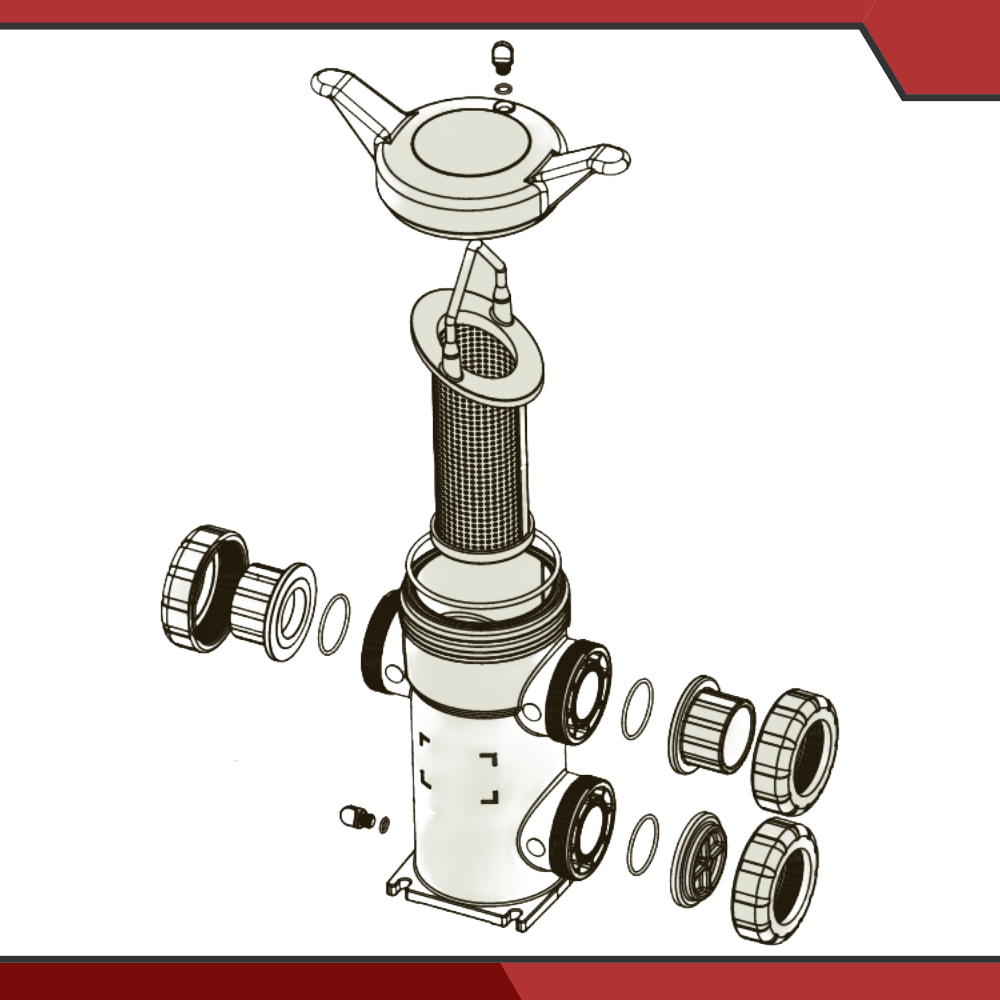

At their core, both simplex and duplex strainers are basket strainers. Basket strainers are closed vessels that use a perforated or mesh-lined basket to capture and remove solid particles from a fluid stream. The main difference between these two lies in their design and how they handle maintenance.

Simplex Strainers

A simplex strainer is made with a single basket chamber. When the basket fills with debris and needs to be cleaned, the entire pipeline flow must be temporarily shut down. This design makes simplex strainers a more straightforward and cost effective solution for plumbing systems that can accommodate pauses, such as batch processing or applications where downtime is acceptable.

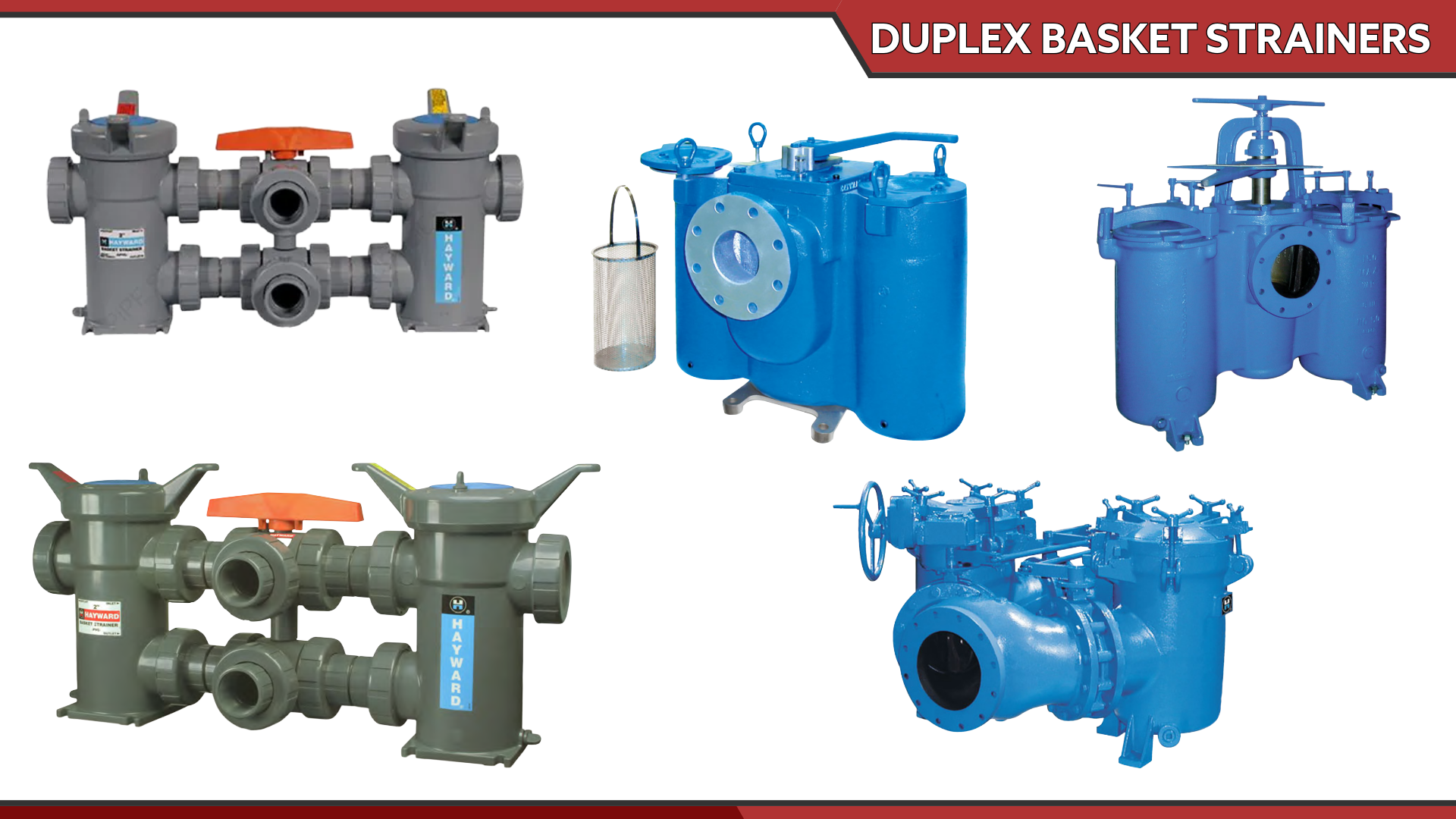

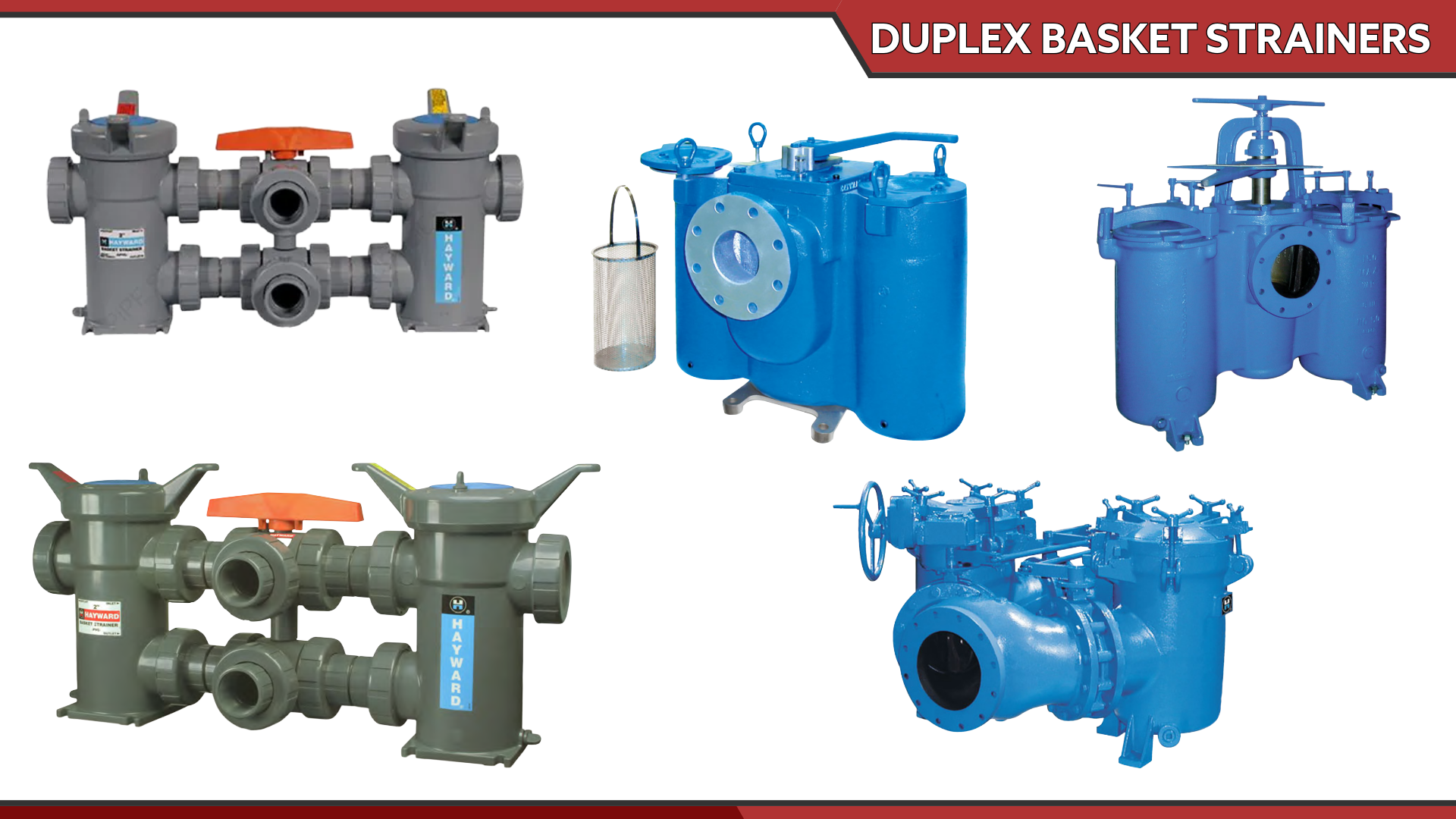

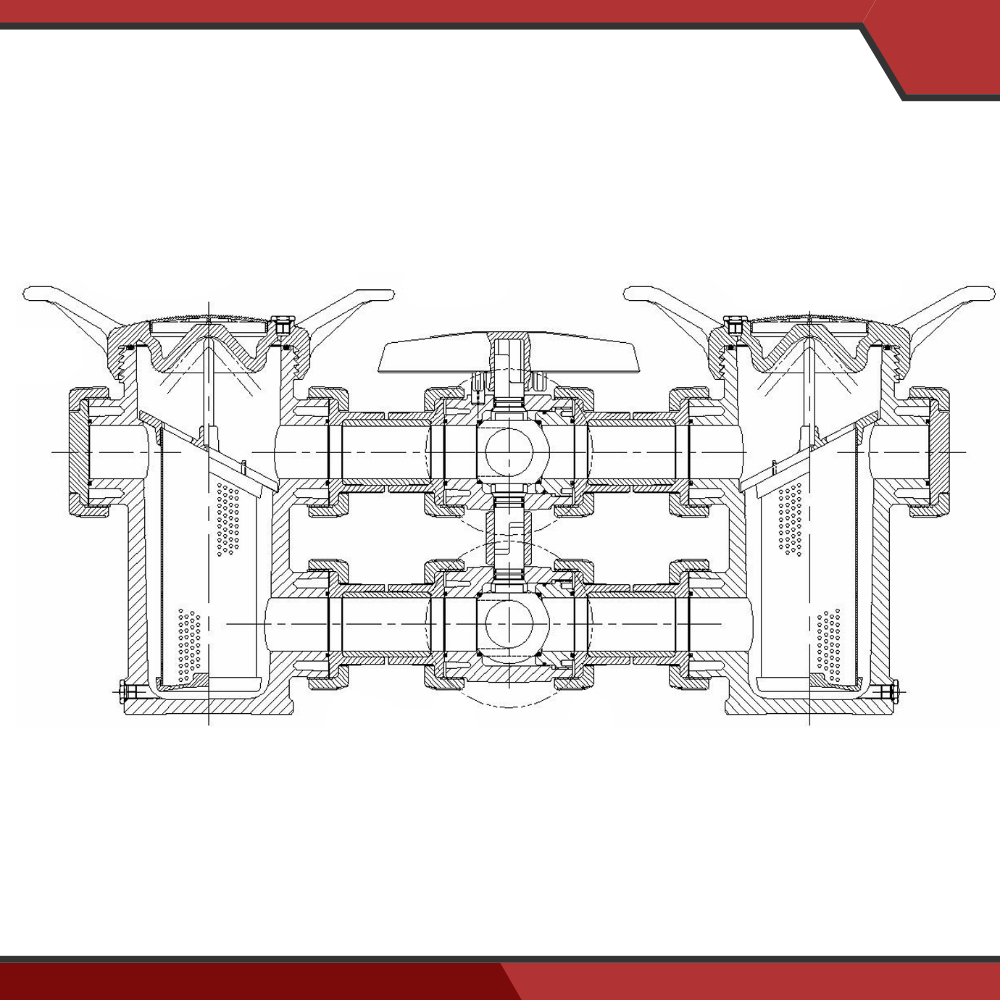

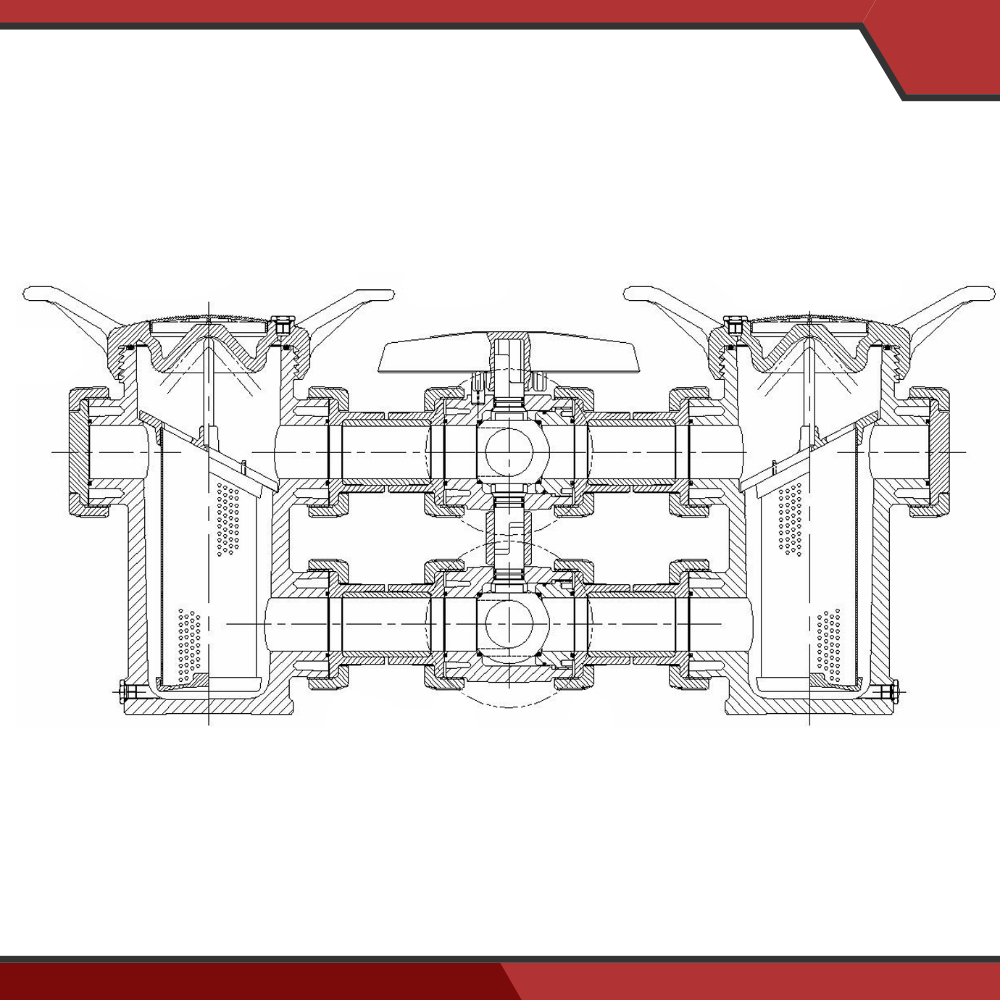

Duplex Strainers

Duplex strainers are made with two separate basket chambers connected by a valve system. This dual design allows flow to be diverted from one chamber to the other without interrupting the overall pipeline flow and operation. When one basket is full, an operator can switch the flow to the clean, standby basket and perform maintenance on the first one. This makes duplex strainers the best choice for continuous flow operations where system shutdown is not an option.

Key Features and Specifications

While their primary function is similar, the construction and features of simplex and duplex strainers are built to match their intended operational environments.

Simplex Strainer Features

- Single Basket Design: The simple, one basket design makes these strainers easy to install and maintain. Accessing the basket is typically a quick process involving a hand removable cover.

- Large Filtration Area: Compared to other in-line plumbing strainer types like Y strainers, simplex basket strainers offer a much larger screen area. This allows them to be more effective at filtration and hold more debris before cleaning is required as well as help minimize pressure drop across the system.

- Versatile Materials: PVC Pipe Supplies offers simplex strainers in a range of materials, including PVC, CPVC, GFPP for corrosive fluids, and durable metals like cast iron, bronze, and stainless steel for heavy duty industrial applications.

- Customizable Filtration: Baskets are available in several perforation sizes to capture larger particles or fine mesh screens for finer filtration, with options down to 400 mesh.

Duplex Strainer Features

- Dual Basket System with Valve: The defining feature is the two chamber design linked by a three way valve or a series of butterfly valves. This allows for continuous operation, as one basket is always online, even while the other is being serviced.

- Uninterrupted Flow: The ability to switch between baskets without stopping the pipeline makes duplex strainers ideal for critical operations that must run 24/7.

- Robust Construction: Built for demanding environments, these pipeline strainers are built from corrosion resistant materials like stainless steel, carbon steel, and specialized plastics like PVC and CPVC to ensure long term reliability.

- Compact Designs: Many duplex strainers feature a direct flow through design that makes them easy to integrate into existing piping configurations without requiring significant extra space.

Common Applications for Each Strainer

The choice between a simplex and duplex strainer often comes down to the specific demands of the industry and application.

Simplex Strainer Applications

Because they require temporary shutdown for cleaning, simplex strainers are best suited for:

- Batch Operations: Perfect for manufacturing lines where production occurs in set batches and maintenance can be performed between cycles.

- Agricultural Irrigation: Used to filter debris from water sources to prevent the clogging of nozzles and sprinklers in systems that are not in constant use.

- Wastewater Treatment: Good for initial filtering stages where flow can be diverted or briefly paused.

- Food & Beverage Processing: Ideal for smaller scale production or processes that are not continuous, such as filtering syrups, oils, or juices.

- Marine Systems: Employed in secondary systems on vessels where flow can be stopped for maintenance.

Duplex Strainer Applications

For industries where continuous operation is non-negotiable, duplex strainers are the go-to solution:

- Chemical Processing: Ideal for protecting sensitive equipment and ensuring product purity without halting production.

- Power Plants & Cooling Systems: Used to filter water for cooling towers and condensers that demand contaminant-free water and must run continuously to prevent overheating.

- Oil & Gas Refining: Ideal for filtering fuels and other fluids in pipelines that operate around the clock.

- High Volume Food & Beverage Production: Ensures uninterrupted processing of products like milk, juice, and other liquids in large scale manufacturing facilities.

- Pharmaceuticals & Biotech: Guarantees clean, continuous flow in sensitive processes where contamination and downtime are not acceptable.

How to Choose the Right Strainer for Your Needs

Selecting the right strainer is a decision that can impact the efficiency, reliability, and operating costs of your piping system. Consider these points on how to choose the right strainer:

- Flow Requirements: Can your process be stopped for maintenance? If the answer is no, a duplex strainer is the clear choice. If brief interruptions are acceptable, a simplex strainer may be the better and more economical choice.

- Particle Load: How much debris do you expect? For systems with a high volume of particles, a duplex strainer allows for frequent cleaning without downtime. For less heavy particle loads, a simplex strainer may be the best option for when only occasional cleaning is needed.

- Material Compatibility: Ensure the strainer housing and basket material are compatible with the liquid in your pipeline. PVC Pipe Supplies offers strainer material options for everything from clean water to highly corrosive chemicals.

- Operational Costs: While duplex strainers have a higher upfront cost, they can save money over time by preventing the loss that can occur from regular downtime in systems that require continuous operation. In these scenarios, evaluate the long term cost from production losses versus the initial investment.

Find the Perfect Strainer at PVC Pipe Supplies

Choosing between a simplex and duplex strainer will ultimately depend on balancing your application needs with your budget. Simplex strainers offer a reliable and affordable solution for on-off processes, while duplex strainers provide the uninterrupted performance necessary for continuous flow operations. By understanding these key differences, you can protect your equipment, ensure product quality, and optimize your system's performance.

Whether you need the straightforward use of a simplex strainer or the continuous reliability of a duplex model, PVC Pipe Supplies has a comprehensive selection to meet your project’s demands. Explore our range of high quality simplex strainers and duplex strainers today or contact our experts for help on finding the perfect fit for your system.