PVC pipes are an essential building material to a range of modern projects, from residential plumbing and waste handling to industrial facilities, commercial applications, and even DIY creations. Known for their durability, affordability, and adaptability, these pipes have become a go-to solution for both professionals and hobbyists. Whether you're routing water lines, drain pipes, irrigation or chemical conveyance systems, or constructing furniture, displays, toys, or building structures for a garden, PVC pipes provide the strength and flexibility needed to bring the blueprint to life.

However, not all PVC pipes are created equal. Selecting the wrong type can lead to inefficiencies, increased costs, or a failed project. As an example, a pipe designed for a high pressure system would be over-engineered — and unnecessarily expensive — for an outdoor project like a custom made greenhouse. Similarly, using a polished, vibrantly colored pipe in an underground irrigation system would waste its aesthetically focused design, not to mention unsafe. Matching the right pipe to the task is vital to ensure that your project functions as intended for the best price and performance.

This article will focus on two widely used types of PVC pipes: Schedule 40 PVC, also known as white or traditional PVC pipe, and furniture grade PVC pipe. By the end, you'll have a clear understanding of their differences, strengths, and ideal applications so you can confidently select the best option for your needs.

Overview of PVC Pipes

PVC, or Polyvinyl Chloride, is one of the most widely utilized materials in modern construction, plumbing, and creative design projects. It is popular due to its combination of impressive characteristics that make it a reliable and versatile choice for numerous applications.

- PVC is durable and resists wear and tear even under daily use, making it a staple option in both residential and industrial setups.

- Its lightweight nature makes handling and installation easy, which in turn reduces effort and how long projects take to complete.

- PVC is also chemically resistant and can withstand exposure to water as well as many chemicals and other corrosive agents without deteriorating.

These properties work together to make PVC a budget friendly, effective material suitable for a range of structural and functional applications.

|

|

|

What Is Schedule 40 PVC?

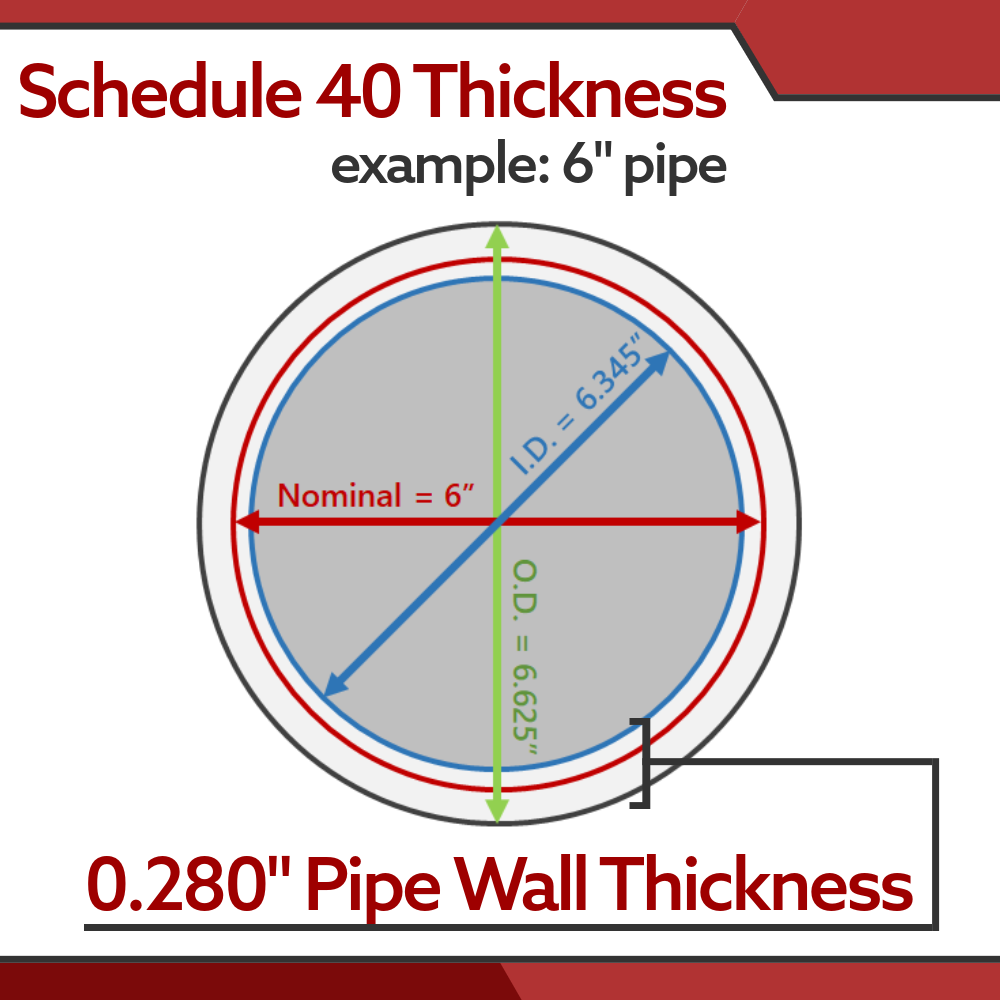

The term Schedule 40 refers to a standardized specification for the thickness of the pipe walls and the liquid pressure the PVC pipe can safely handle. This specification is governed by ASTM (American Society for Testing and Materials) standards. Its purpose is to ensure consistent performance of products made by different manufacturers. Schedule 40 pipes are engineered with moderate wall thicknesses for a balance between strength and affordability.

The thickness of Schedule 40 pipes determines its maximum pressure rating. For example, a Schedule 40 pipe with a 1 inch diameter can withstand water pressures of approximately 450 psi (pounds per square inch) at room temperature. However, this pressure rating decreases as pipe size and operating temperatures increase, known as a de-rating factor.

Schedule 40 Traditional PVC Pipes

Traditional Schedule 40 PVC pipes are made for demanding tasks involving pressurized systems or liquid transport. Their robust construction allows them to handle applications such as:

- Water supply lines

- Sprinkler and irrigation lines

- Chemical conveyance

- Sewage systems

These pipes are essential to modern residential plumbing, agricultural irrigation, and many industrial workflows as they offer long term reliability at a reasonable cost. Standard white PVC pipes feature printed manufacturer markings, which report important details like size, pressure rating, and certifications that apply to the pipe, as is required to comply with national safety standards.

Schedule 40 in Furniture Grade PVC Pipes

Although both traditional and furniture grade pipes share the same Schedule 40 specification for pipe thickness, their differences lie in their manufacturing process, additives, finish, and intended purpose. Furniture PVC pipes retain the same wall thickness, but they are manufactured with a focus on aesthetics and are not certified for plumbing use with potable water or pressurized applications, and should not be used for this purpose. Furniture pipes are unmarked with a high gloss finish, making them ideal for visible or decorative applications like:

- Custom furniture

- Garden structures

- Recreational items

- Creative displays

Despite their emphasis on appearance, furniture pipes have a high structural integrity that often outperforms standard PVC on impact resistance.

Key Differences Between Traditional PVC and Furniture Grade PVC pipes

Below, we break down the key differences between traditional PVC and furniture grade PVC pipes.

1. Material and Additives

Traditional PVC is engineered for functionality and strength. Its manufacturing focuses on delivering durability and pressure resistance, making it suitable for applications like plumbing, drainage, and chemical transport. The material is designed to withstand significant wear, exposure to corrosive agents, and high internal pressure for long term reliability even in demanding environments. Standard white PVC pipe often does not include ultraviolet (UV) stabilizers, making it susceptible to sunlight damage over time. For more on this, see PVC & CPVC Pipe Sunlight Resistance. Due to this, traditional PVC pipe is best suited for indoor and underground installations.

Furniture Grade PVC, on the other hand, is built for visual appeal without losing structural integrity. These pipes are manufactured with a polished finish and embedded with UV inhibitors to resist fading and brittleness caused by sunlight exposure. While they aren’t designed to handle pressurized systems or demanding workloads, their material is optimized for lasting aesthetics and decorative use, making them ideal for structures and creative projects both indoors and outdoors.

2. Markings and Appearance

Traditional PVC pipes have visible manufacturer markings that repeat along their surfaces. These markings include critical specifications like size, pressure ratings, and certifications. While these labels ensure compliance and clear identification during installation, they can subtract from the pipe's appearance in exposed projects.

Furniture Grade PVC pipes, in contrast, are entirely free from any markings, labels, or barcodes. Its high gloss, smooth surface is clean and offers a professional finish perfect for projects intended to be seen. This unmarked design helps blend the transition between pieces for a uniform, nearly seamless look.

3. Color Options

Traditional PVC is typically only available in the color white, sometimes grey. These neutral tones help keep costs low and are well suited for functional applications such as underground plumbing or concealed water lines.

Furniture Grade PVC offers a vibrant range of colors, including red, blue, green, yellow, black, and more. This wide color selection allows customization and design flexibility and is the primary reason furniture PVC pipes are a popular choice for creative and decorative projects. Matching colorful pipes with similarly vibrant PVC furniture fittings can enhance the look of custom furniture, outdoor structures, and artistic displays.

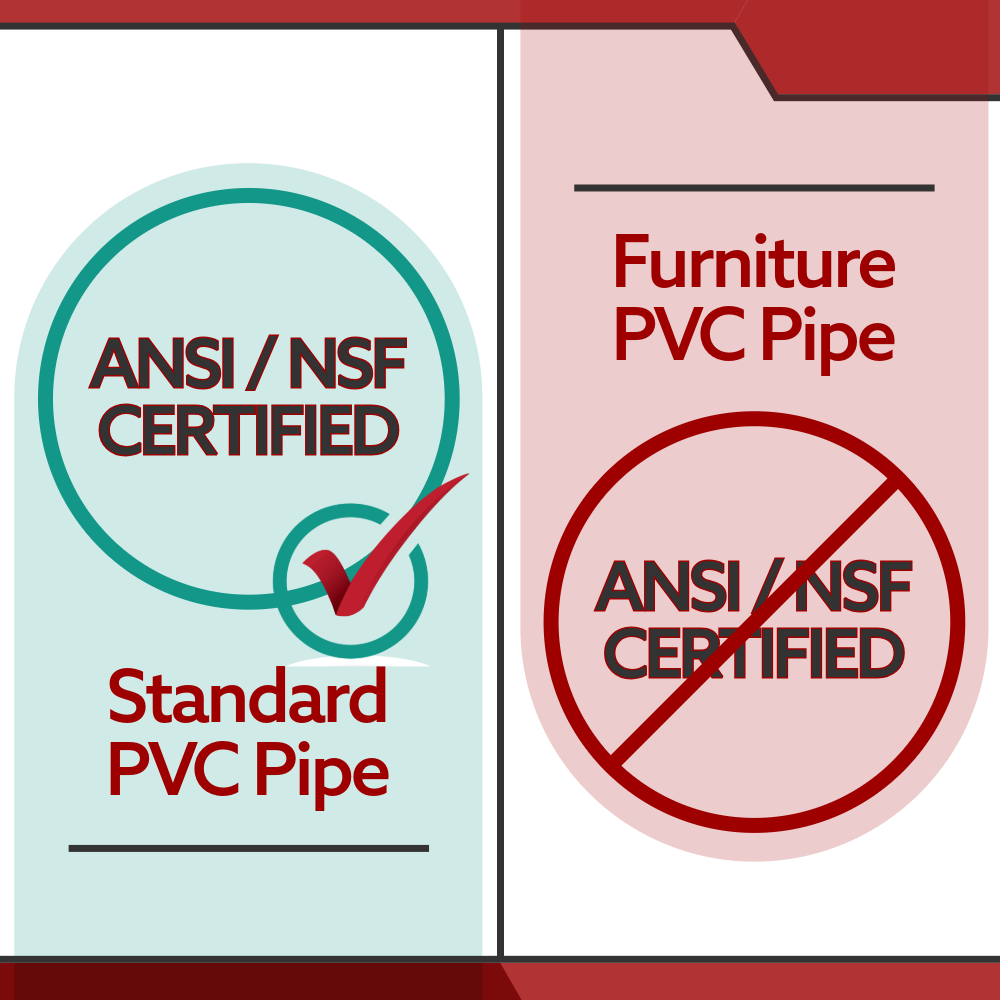

4. Certifications

Traditional PVC pipes are ANSI / NSF certified, which guarantees the plumbing is safe for carrying potable (drinkable) water intended for human consumption. Additionally, its engineering and design testing must meet or exceed ASTM standards for pressurized systems and reliability.

Furniture Grade PVC pipes, however, are not NSF approved and, therefore, are unsuitable for handling freshwater or water pressure. The pipes are also not tested to ASTM requirements for use in pressurized systems, restricting their use to decorative builds.

Understanding the key differences between traditional and furniture grade PVC pipes will ensure you select the right material for your project. Whether you need functional, pressure resistant pipes for plumbing or colorful, polished pipes for a DIY build, each type of PVC offers unique advantages.

Applications and Use Cases

Traditional PVC Applications

Traditional PVC pipes are the backbone of functional and high performance applications due to their durability, pressure resistance, and ability to handle demanding systems. Below are its key applications and uses:

|

1. Plumbing and Irrigation SystemsTraditional PVC pipes are commonly used in residential and commercial plumbing projects. Their ability to handle pressurized water makes them ideal for water supply lines and indoor plumbing. Contractors and homeowners frequently use these pipes for their ease of installation, low maintenance, and long service life. They are widely used in outdoor irrigation systems to water lawns, gardens, or food plots. |

|

2. Industrial Piping for ChemicalsIndustries often use traditional schedule 40 PVC pipes for the transport, storage, and distribution of chemicals, ingredients, and various solution mixtures. PVC pipes resist corrosion and chemical damage, making them suitable for handling various compatible fluids like acids and alkalis. For more aggressive chemicals, consider using CPVC pipe or PVDF pipe. From chemical production to manufacturing and food processing plants to wastewater treatment facilities, Schedule 40 PVC excels in safe fluid conveyance. Its compliance with ASTM and NSF standards further ensures that industries can depend on PVC pipe for their regulated applications. |

|

3. HVAC Ductwork and Drainage SystemsThe versatility of Schedule 40 PVC extends to HVAC systems, where it is used for low-pressure ductwork as well as venting and exhaust applications. The non-corrosive nature of PVC makes it effective in environments where traditional metal piping may degrade over time. Additionally, it is a favored choice for drainage systems, as its smooth interior helps prevent clogs and ensures efficient flow. Whether installed in commercial buildings or residential complexes, Schedule 40 PVC contributes to long-lasting, cost-effective performance in fluid management systems. Schedule 40 PVC, also known as duct pipe, is widely used in HVAC systems for low pressure ductwork, venting, and exhaust. Its corrosion resistant nature makes it ideal for applications where metal piping would degrade. It's also the primary choice for drain, waste, and vent systems, known as DWV pipe and fittings. PVC has a smooth interior that prevents clogs and keeps flow consistent. |

Furniture Grade PVC Applications

Furniture grade PVC is designed for creativity and a professional, finished look that is ideal for innovative, non-pressurized builds. Below are examples and uses:

1. DIY Furniture

Furniture grade PVC pipe and fittings are commonly used to create a wide range of custom DIY furniture pieces, including tables, bookshelves, storage racks, and chairs. Hobbyists also use furniture pipe to craft shoe racks, coat stands, plant stands, and even bed frames. Its flexibility makes it perfect for modular shelving units, rolling carts, or portable desks, while its color options allow for personalized, stylish designs. Whether you're building a compact workspace, a kid’s toy organizer, or an artistic display unit, furniture grade PVC is the material of choice.

2. Garden Structures

Furniture grade PVC is perfect for building durable, weather proof, and sun resistant garden structures. It's commonly used for trellises to support climbing plants, greenhouses to protect crops, pergolas for shaded seating, and even raised garden beds or low flow, non-pressurized irrigation systems. Its UV resistance and cleanable outer finish make it ideal for outdoor use while staying functional and visually appealing.

3. Recreational Builds

Furniture grade PVC is used to build recreational and hobby projects. It's commonly used to build pet enclosures like animal pens or reptile habitats, as well as play structures such as jungle gyms, mini soccer goals, or obstacle courses. Its lightweight and durable nature makes these projects safe, portable, and easy to assemble and disassemble. Other popular DIY uses include crafting sports equipment racks, display stands, or even custom gardening tools. With furniture grade PVC, you can easily turn creative ideas into practical builds.

|

|

|

Pros and Cons of PVC

Traditional PVC Pipe

Pros:

|

Cons:

|

Furniture Grade PVC

Pros:

|

Cons:

|

Tips for Selecting the Right PVC Pipe

Choosing the right PVC pipe is essential for project success, whether you're designing a robust plumbing system or crafting visually appealing furniture. Here are four tips to select the right PVC pipe:

1. Evaluate Project Requirements

Define the purpose of your project and the role the pipe will play.

- Functional Needs: If your project involves pressurized water, waste or vent handling, industrial type liquids, or irrigation, choose Schedule 40 PVC.

- Aesthetic Goals: For exposed, decorative, or creative applications with a purpose like DIY furniture, displays, and garden structures, furniture grade PVC is the better choice due to its polished, professional finish and color variety.

2. Consider Environmental Factors

The environment in which the pipe will be used can play a large role in its durability and longevity.

- Outdoor Use: If the pipes will be exposed to sunlight, consider whether the pipe is UV resistant or if additional measures will be necessary. Furniture grade PVC is made with UV inhibitors to resist fading and brittleness, making it ideal for outdoor projects. For outdoor plumbing systems, ensure Schedule 40 PVC is coated, covered, placed in a shaded area, or installed underground to protect it from long term UV exposure.

- Weather Conditions: Extreme temperatures or wet environments may affect pipe performance. Ensure the selected PVC type is suitable for the conditions where it will be installed.

3. Ensure Compatibility Between Pipes and Fittings

Proper compatibility between pipes and fittings is necessary to achieve a secure installation and long term performance.

- Schedule 40 PVC fittings are standardized across manufacturers, which ensures broad compatibility with pipes of the same type.

- For furniture grade PVC, fittings are specifically made to complement the smooth, unmarked surface and vibrant colors of the pipes. Always match furniture grade fittings to furniture grade pipes to maintain a cohesive and secure appearance.

Double check dimensions and verify all components align with your project’s specifications to prevent delays or issues during assembly.

4. Factor in Certifications and Safety Requirements

Certifications demonstrate that a product meets industry standards for safety and performance.

- Use NSF certified Schedule 40 PVC pipe for potable water and pressurized systems to comply with health and safety requirements.

- Do not use furniture grade PVC in systems that involve drinking water or water pressure, as it is not designed or certified for these applications.

Get What you Need from PVC Pipe Supplies

Understanding the distinct strengths and design differences of traditional PVC and furniture grade PVC pipe allows you to make the right decisions for any project. Standard schedule 40 PVC excels in functional, high pressure systems like plumbing, chemical transport, and industrial applications where strength and durability are priority. Meanwhile, furniture PVC stands out for its polished and colorful appearance that makes it the ideal choice for decorative or creative DIY projects such as furniture, garden structures, and recreational items.

Before making a purchase, evaluate your project’s requirements, consider where it will be built as well as other environmental factors, make sure parts are compatible, and check for certifications if relevant.

To simplify your shopping, PVC Pipe Supplies offers an extensive selection of both Schedule 40 and furniture grade PVC pipes as well as all the fittings you need. Find everything for your next project, learn more about pipes, their specs and uses, or take advantage of our bulk order options, all at PVC Pipe Supplies. With our lowest price guarantee and professional quality products, we have everything to take your project from blueprint to plan to reality.