|

Need precise fluid management? The right flow meter helps you optimize performance, save resources, and ensure system safety—whether it’s tracking water, dosing chemicals, or measuring material flow. PVC Pipe Supplies offers professional grade flow meters for commercial, industrial, and municipal needs. Our selection includes everything from cost effective mechanical designs to precise, programmable digital meters with LCD displays. Whatever your project requires, we have the solution. This guide explores mechanical, digital, ultrasonic, and magnetic flow meters, explaining how they work, their benefits, and ideal applications to help you choose the right solution for your fluid management needs. |

Need precise fluid management? The right flow meter helps you optimize performance, save resources, and ensure system safety—whether it’s tracking water, dosing chemicals, or measuring material flow.

PVC Pipe Supplies offers professional grade flow meters for commercial, industrial, and municipal needs. Our selection includes everything from cost effective mechanical designs to precise, programmable digital meters with LCD displays. Whatever your project requires, we have the solution.

This guide explores mechanical, digital, ultrasonic, and magnetic flow meters, explaining how they work, their benefits, and ideal applications to help you choose the right solution for your fluid management needs.

Mechanical Flow Meters

Mechanical flow meters are a reliable, simple, and efficient solution for monitoring liquid flow rates. Built for durability and ease of use, these meters are ideal for a variety of applications from residential to industrial. Among the available options, inline installation flow meters and AcuFlow flow meters are the main products.

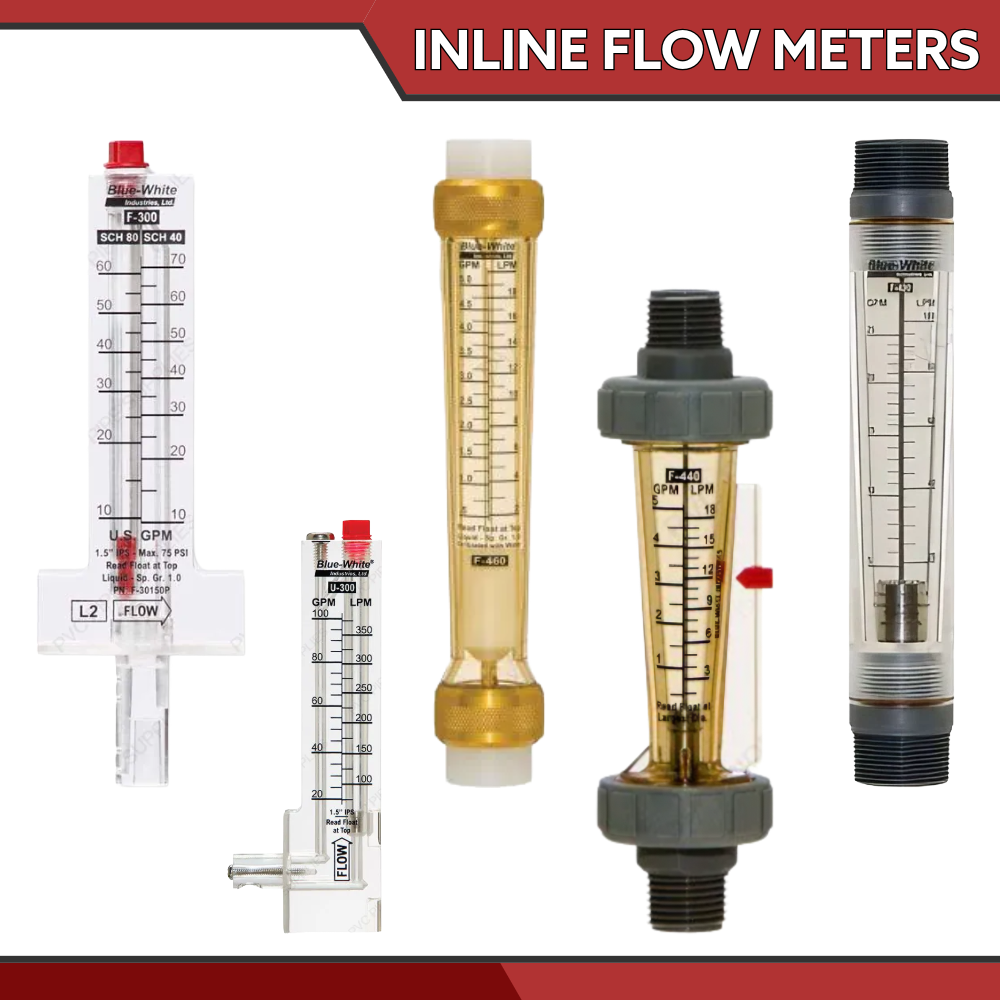

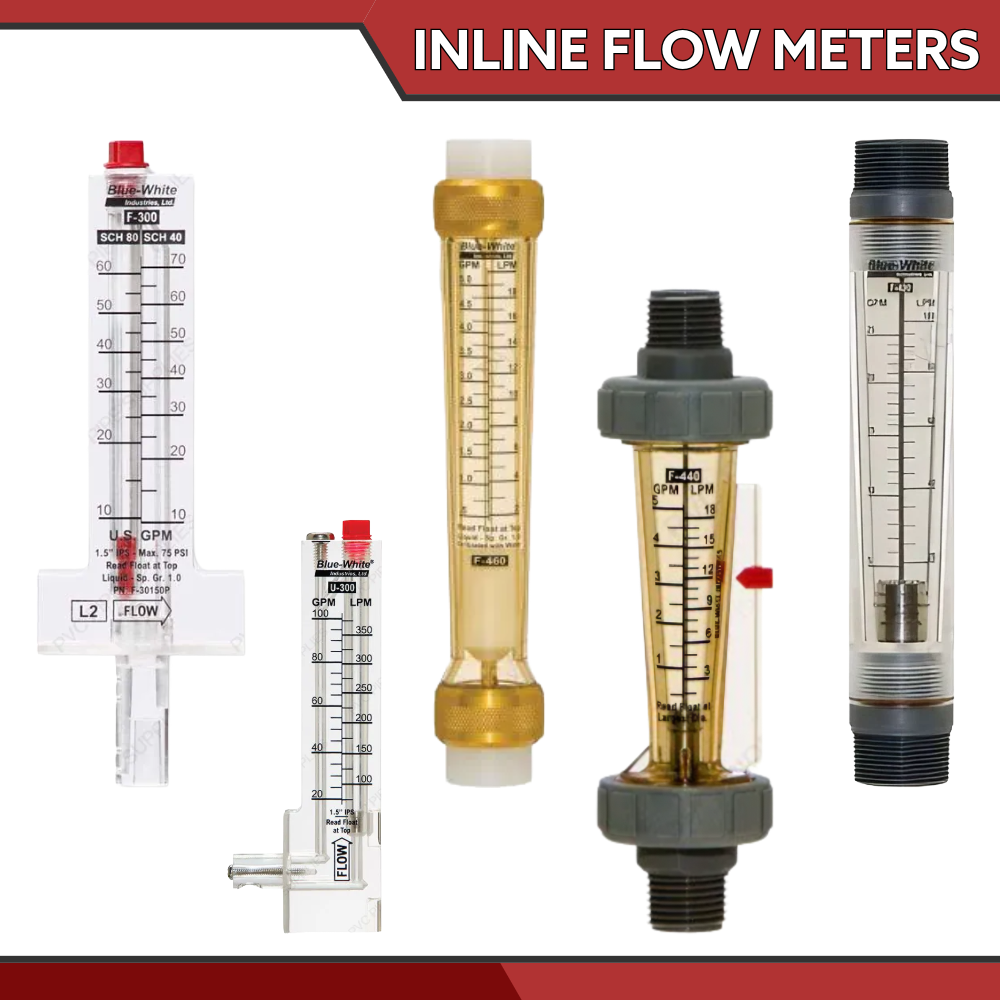

Inline Installation Flow Meters

Inline flow meters are a practical choice for straightforward fluid rate monitoring. These meters are designed to fit seamlessly into piping systems. They are compact and durably made to ensure long term performance.

Key Features:

- Compatible with various pipe sizes from 1/4" to 8”

- Micro to macro flow rates from 0.025 GPM to 1900 GPM

- Clear, easy-to-read measurement displays

- Robust design to withstand regular usage and environmental factors

Applications:

- Agriculture and Irrigation

- Aquatics, Aquariums, and Pools

- Food and Beverage

- Industrial Water & Wastewater Treatment

- Municipal

- Reverse Osmosis Purification Systems

- Water Boiler Treatment

AcuFlow Flow Meters

AcuFlow flow meters use a flapper-type component with a visual rate dial for flow rate measurement. These meters use a patented design based on mass flow principles to provide accurate and reliable results. With their integrated check valve functionality and flexible orientation options, AcuFlow meters are made to accommodate various configurations.

Key Features:

- Flapper based operation for precise flow rate measurement

- Flow rates from 10 GPM to 1800 GPM

- Easy installation without the need for extensive straight pipe runs

- Built in check valve for added system protection

- Designed for long life with minimal maintenance requirements

Applications:

- PCB and Semiconductor Production

- Aquariums

- Food and Beverage

- Chicken Farming

- Commercial Laundry

- Fracking and Petroleum Production

- Groundwater and Reclamation

- Medical and Pharmaceutical

- RO and Ultra Pure Water

Mechanical Flow Meters from PVC Pipe Supplies

At PVC Pipe Supplies, we have a range of high quality mechanical flow meters to meet different plumbing systems and needs. These products are built for reliability and ease of use in applications from residential to industrial. To explore the full range of mechanical flow meters and find your ideal solution, browse PVC Pipe Supplies’ Mechanical Flow Meters today. These cost effective and dependable options offer accurate measurements without compromising on durability.

Takeaway

Mechanical flow meters offer a practical, budget friendly solution for monitoring liquid or gas flow in various piping systems. Their simplicity, durability, and no electricity requirement make them an excellent choice for residential and basic industrial applications. While they may lack the advanced precision and features of digital models, their reliability and ease of use make them indispensable for many fluid management needs.

Digital Flow Meters

Digital flow meters are among the top of modern fluid management technology, designed to deliver exceptional precision, versatility, and control. These products utilize electronic technology to report and monitor flow rates. Digital flow meters are technically a catch-all for flow meters with an electronic display and additional programmable features and integration capabilities such as data loggers and alarms. Therefore, digital flow meter types include paddle wheel, ultrasonic, and magnetic flow meters.

Key Features of Digital Flow Meters

- Totalizers for Cumulative Flow Measurement: Digital flow meters are often equipped with totalizers, which track the total volume of fluid passing through the system over time. This feature is greatly beneficial for long term monitoring and making sure operating benchmarks are being met.

- Alarms for Irregular Flow Detection: One standout feature of digital flow meters is their ability to detect irregularities in flow patterns. Compatible alarms quickly notify users of deviations such as surges, blockages, or leaks to enhance system safety and efficiency.

- Batch Processing Capabilities: Precision is key in many applications, especially those involving repeating cycles for production. Many digital flow meters support programmable batch processing that allows users to pre-set specific flow volumes and achieve consistent and controlled operations.

Benefits of Digital Flow Meters

- High Precision and Programmability: These meters offer unrivaled accuracy in measuring flow rates and total volumes, making them ideal for applications requiring exacting standards. Their programmability further enhances functionality, allowing users to configure settings for specific tasks and environmental conditions.

- Easy to Read Digital Displays: Digital readouts make digital flow meters user friendly, ensuring that operators can quickly and easily interpret data. Many models also include additional functionalities such as backlit displays for low light environments.

Common Applications

Digital flow meters are essential in industries that require accurate and automated flow management. Here are some of their most common applications:

- Chemical Dosing in Water Treatment: Accurate chemical dosing is critical for maintaining water quality. Digital flow meters ensure precise control over chlorine, fluoride, or other additives while optimizing dosing processes.

- Ingredient Measurement in Food and Beverage Production: Consistency is key in the food and beverage sector. Digital flow meters monitor and control ingredient quantities during mixing and batching operations for uniform quality and production.

Digital Flow Meters from PVC Pipe Supplies

PVC Pipe Supplies offers a comprehensive selection of digital flow meters designed to meet the demands of modern fluid management. Their offerings include models that feature:

- Flow rates from 0.008 GPM to 8000 GPM

- Programmable controls for batch processing

- High resolution digital displays that provide real-time flow data

- Durable construction for use in challenging environments

Takeaway

Digital flow meters provide unmatched precision, functionality, and ease of use for fluid management applications. With features like totalizers, alarms, and batch processing, they address the needs of industries that require highly accurate and programmable solutions. Whether in water treatment, manufacturing, or food and beverage production, their benefits are clear. Browse the digital flow meters available at PVC Pipe Supplies to find the perfect product.

Other Types of Flow Meters

Flow meters come in many variations to match specific fluid management needs. Among the top options are ultrasonic and magnetic flow meters, each with unique designs and applications. Here’s a closer look at these types, their features, and where they’re most commonly used.

Ultrasonic Flow Meters

Ultrasonic flow meters stand out for their non-intrusive design, which allows fluid flow to be measured from outside the pipe without requiring modifications. These meters use sound waves to calculate flow rates, ensuring that the internal structure of pipelines remains untouched. This non-invasive measurement method makes ultrasonic flow meters ideal for applications where preserving pipe integrity is crucial and material-to-chemical compatibility is a concern.

Advantages:

- No dead volume

- Excellent chemical resistance

- Ideal for clean water, non-conductive, or hazardous fluids

- Works on PVC, CPVC, PP, PVDF, PE, stainless steel, copper pipe

- No moving parts, durable, low maintenance

- Easy installation, no cutting, no need to shut down operations

Applications:

- Liquid chemical flow measurement

- Filtration systems

- Water and wastewater monitoring

- Industrial chemical distribution

- Process chemical skids

- Liquid consumption

- Discharge verification

PVC Pipe Supplies offers ultrasonic flow meters built for precise applications and reliable performance in demanding setups.

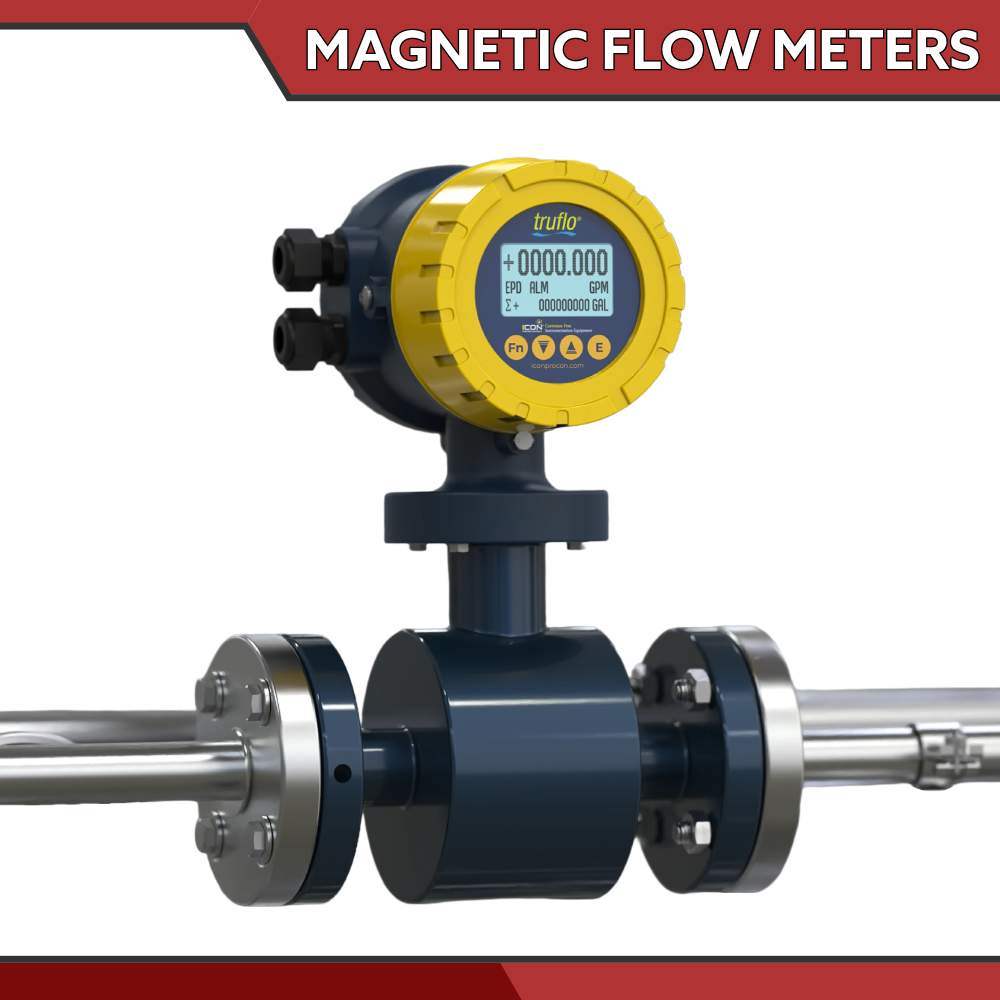

Magnetic Flow Meters

Magnetic flow meters are a go-to solution for measuring conductive fluids, such as chemicals, wastewater, and slurries. These meters use Faraday’s law of electromagnetic induction and electromagnetic fields generated from fluid movement to measure flow, eliminating the need for any moving parts. The result is a highly accurate device that works reliably even with aggressive or contaminated fluids. The magnetic flow meter is also known as an electromagnetic flow meter or mag meter.

Advantages:

- High accuracy, ± 0.5%, even in variable flow rate applications

- Durable design, minimal need for servicing

- Excellent performance, wide range of temperatures and pressures

- No moving parts, no clog design

- Flow meter, totalizer, all in one

- Several options have built-in data logging

Applications:

- Chemical Processing

- Water Treatment

- Food and Beverage Industry

- Mining and Metals

- Pharmaceutical Production

- Pulp and Paper

- Dirty and Viscous Fluids

For industry plumbing systems that require magnetic flow meters, PVC Pipe Supplies provides these tools in a full selection of options to match application compatibility.

Takeaway

Each of these flow meters—ultrasonic and magnetic—addresses specific challenges in fluid management. Ultrasonic meters are non-invasive and suitable for many applications, and magnetic options excel in handling conductive fluids that are difficult for other flow meter types. With a wide range of high quality flow meters, PVC Pipe Supplies ensures you can find the perfect product to suit your company’s needs.

Choosing the Right Flow Meter

Selecting the right flow meter is essential for achieving optimal performance and accuracy in any fluid management system. With a variety of flow meters available, understanding the key factors that influence your choice can help you select the best option for your application. Here’s what to consider:

1. Application Requirements

The first step in choosing a flow meter is to clearly define the application requirements. Consider the following aspects:

- Fluid Type: Is the fluid a liquid, gas, or a mixture? Does it have specific characteristics, such as being conductive, non-conductive, clean, or containing solids? Fluid type plays a primary role in determining the right flow meter.

- Flow Rate: Understanding expected or typical flow rates is another critical point in flow meter selection to choose the meter that is rated to handle the volume accurately. Oversizing or undersizing a meter can lead to performance issues and potential inaccuracies.

2. Environmental Conditions

Environmental factors can impact flow meter performance and longevity. Some key conditions to consider include:

Corrosive Environments: For systems handling harsh chemicals or aggressive substances, materials like PVDF or stainless steel may be necessary to prevent corrosion and maintain functionality.

- Temperature and Pressure: High temperature or high pressure applications require flow meters engineered to withstand such conditions without compromising safety or accuracy.

- Installation Environment: Consider whether the flow meter will be installed indoors, outdoors, or in a confined space. Factors like harsh weather or limited accessibility for maintenance should influence your selection.

3. Budget and Maintenance Needs

Depending on company budgets, cost can play a significant role in decision making, but it’s important to strike the right balance between upfront costs and long term value:

- Upfront Costs: Mechanical flow meters are often more budget friendly, while digital ones offer advanced features that justify the higher initial investment.

- Maintenance Requirements: Simple meter designs, such as mechanical flow meters, may require minimal upkeep, while advanced models, like digital meters, might need periodic calibration. Assessing your team’s capacity for maintenance can help narrow down your options.

PVC Pipe Supplies | Professional Solutions

Flow meters are essential tools in fluid management that come in various product options to meet a wide range of application requirements. From the simplicity and durability of mechanical flow meters to the advanced precision of digital designs and the non-intrusive operation of ultrasonic flow meters, to the compatibility of magnetic meters with conductive fluids, each type brings unique features to match specific needs. Choosing the right flow meter will ensure efficiency, accuracy, and reliability in your system—whether you’re managing water, controlling industrial processes, or maintaining public utilities.

PVC Pipe Supplies offers an extensive selection of high quality flow meters made by trusted manufacturers Blue-White Industries, H2flow Controls, and Icon Process Controls. Our expert team is ready to assist you in finding the perfect solution. Explore our range of flow meters or reach out for personalized guidance today.