|

When a pipe must pass through a concrete wall, floor, or other barrier, creating a permanent, secure seal will be needed to protect the integrity of the structure and the pipeline itself. Link seals provide a modern, reliable, and easy-to-install solution for this exact challenge. As a modular mechanical sealing system, link seals are designed to create a watertight and airtight seal that protects infrastructure from leaks, contamination, and other potential hazards. Link seals feature interlocking rubber links, pressure plates, and tightening bolts. When assembled into a belt and positioned in the space between a pipe and the opening, the bolts can be tightened. This tightening compresses the rubber links, causing them to expand and form a durable, flexible seal. This straightforward mechanism makes link seals effective and essential for countless plumbing, industrial, and commercial applications. |

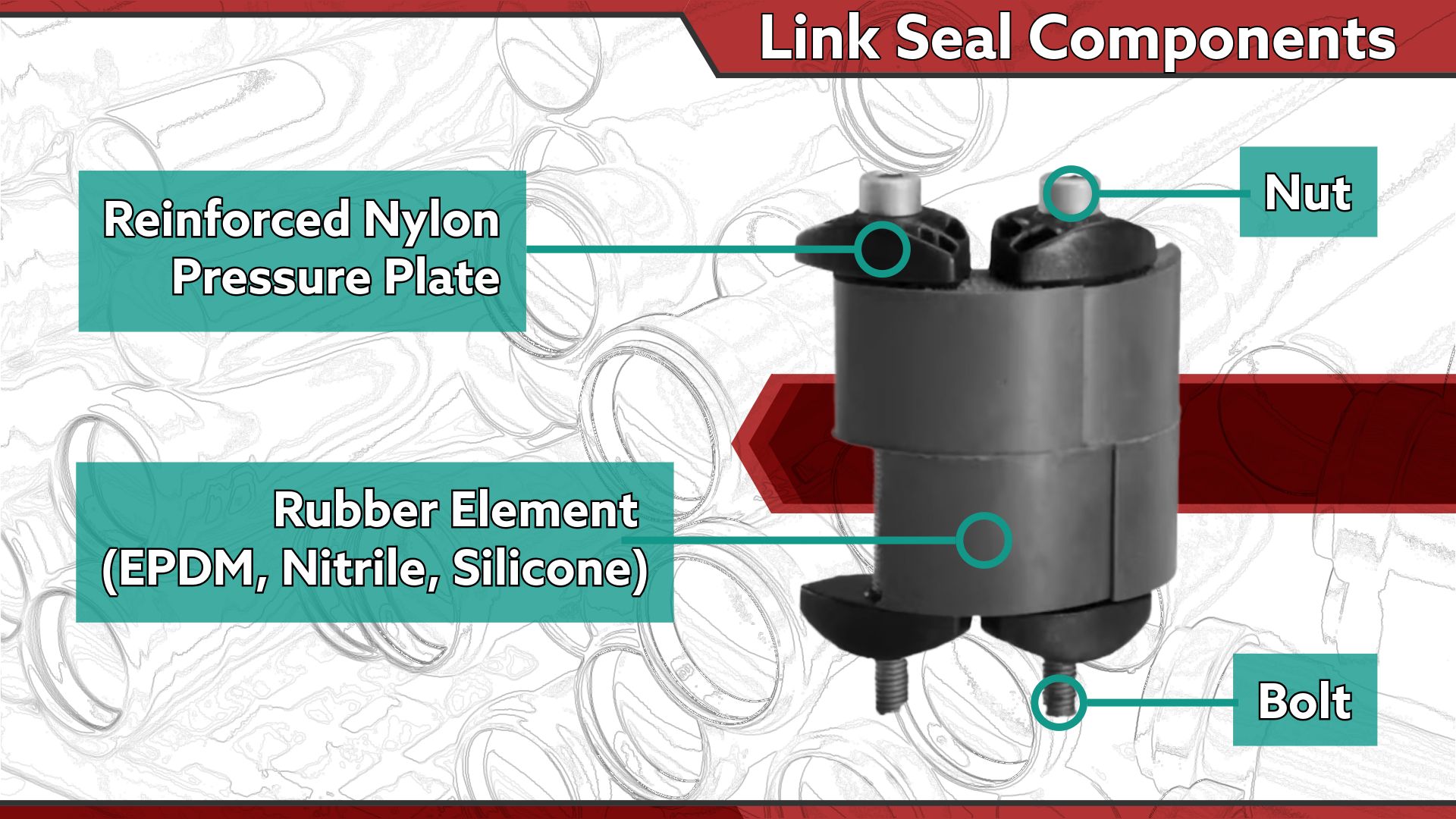

When a pipe must pass through a concrete wall, floor, or other barrier, creating a permanent, secure seal will be needed to protect the integrity of the structure and the pipeline itself. Link seals provide a modern, reliable, and easy-to-install solution for this exact challenge. As a modular mechanical sealing system, link seals are designed to create a watertight and airtight seal that protects infrastructure from leaks, contamination, and other potential hazards.

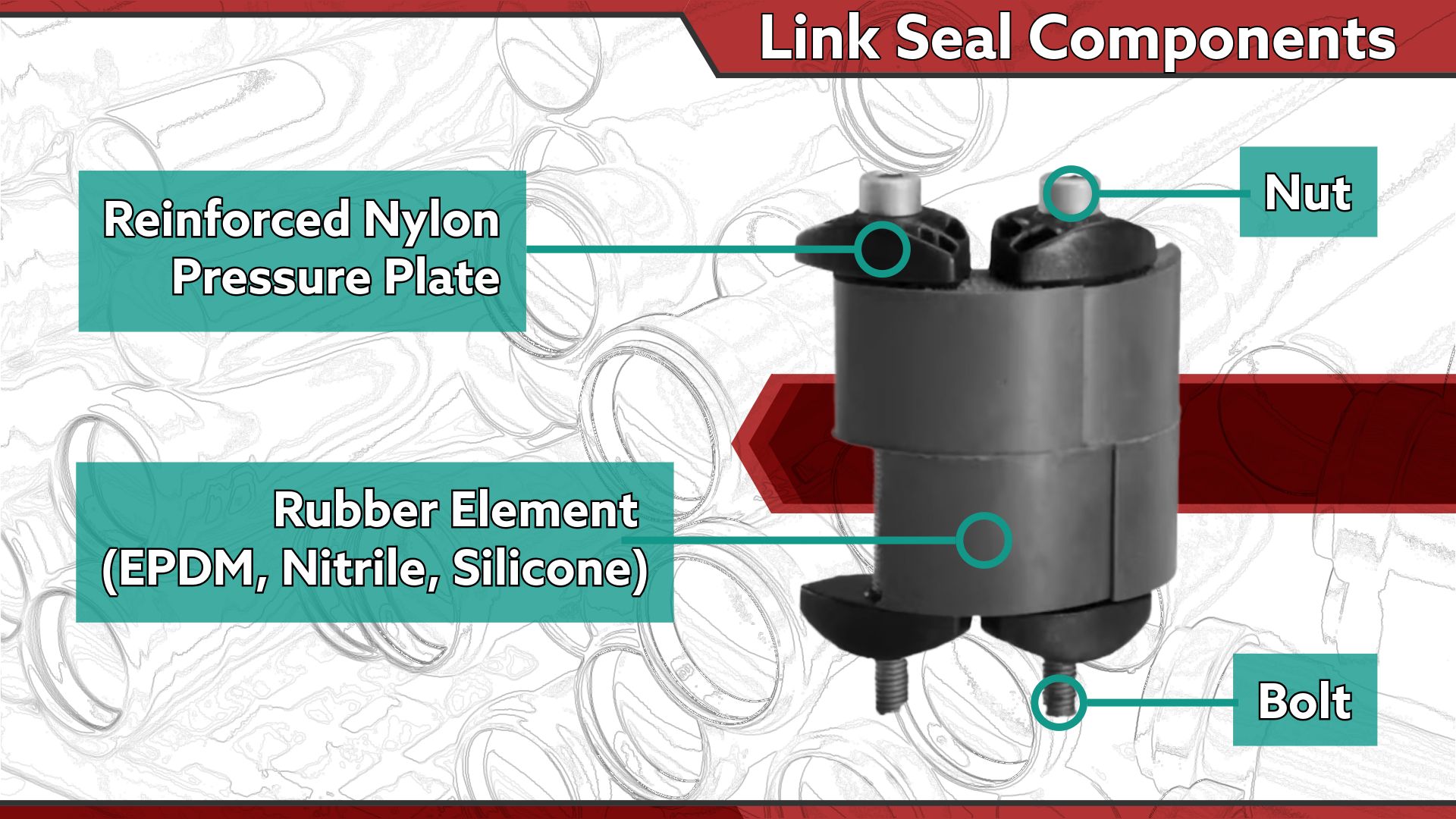

Link seals feature interlocking rubber links, pressure plates, and tightening bolts. When assembled into a belt and positioned in the space between a pipe and the opening, the bolts can be tightened. This tightening compresses the rubber links, causing them to expand and form a durable, flexible seal. This straightforward mechanism makes link seals effective and essential for countless plumbing, industrial, and commercial applications.

Key Features and Benefits of Link Seals

Link seals offer several advantages over other pipe-wall penetration sealing methods like grout or lead-oakum joints. Link seals’ design pivots on superior performance, lasting durability, and ease of use, making them a preferred option and alternative for professionals.

Superior Sealing Performance

The primary function of a link seal is to create an impenetrable barrier that, at the same time, protects the pipe and the barrier from corrosive and physical damage. They deliver a positive hydrostatic seal rated to withstand pressure up to 20 psig, or 40 feet of head pressure. This performance ensures that pipe penetrations are securely protected against water leaks, soil intrusion, and other contaminants that could otherwise compromise the structure or the pipeline.

Durability and Longevity

Built for long term reliability, link seals are manufactured from materials resistant to aging, ozone, sunlight, and a wide range of chemicals. Beyond environmental resistance, they also absorb vibrations, shock, and sound. This feature is vital as it protects pipes from fatigue and damage, particularly at connection points, this in turn extends the lifespan of the entire system.

Durability and Longevity

Built for long term reliability, link seals are manufactured from materials resistant to aging, ozone, sunlight, and a wide range of chemicals. Beyond environmental resistance, they also absorb vibrations, shock, and sound. This feature is vital as it protects pipes from fatigue and damage, particularly at connection points, this in turn extends the lifespan of the entire system.

Installation Efficiency

One of the most significant benefits of link seals is their installation speed. They can be installed in a fraction of the time required for older methods, saving both time and labor costs on a project. A single contractor can typically install a link seal using only basic hand tools, without the need for special chemicals or extended curing times.

Installation Efficiency

One of the most significant benefits of link seals is their installation speed. They can be installed in a fraction of the time required for older methods, saving both time and labor costs on a project. A single contractor can typically install a link seal using only basic hand tools, without the need for special chemicals or extended curing times.

Versatility and Protection

Link seals are incredibly versatile. They effectively isolate the carrier pipe from the wall penetration, which prevents metal-to-metal contact and protects against galvanic corrosion or electrolysis. Further, their flexible rubber design can accommodate slight pipe misalignment and movement to ensure the seal remains intact even if minor settling or shifting occurs.

Takeaway

Link seals are trusted by industry professionals for their reliability. When installed correctly, they consistently prevent water leakage, even in challenging conditions.

Common Applications for Link Seals

The versatility and reliability of link seals make them suitable for many applications across numerous industries. Contractors, engineers, and facility managers depend on them to protect their infrastructure.

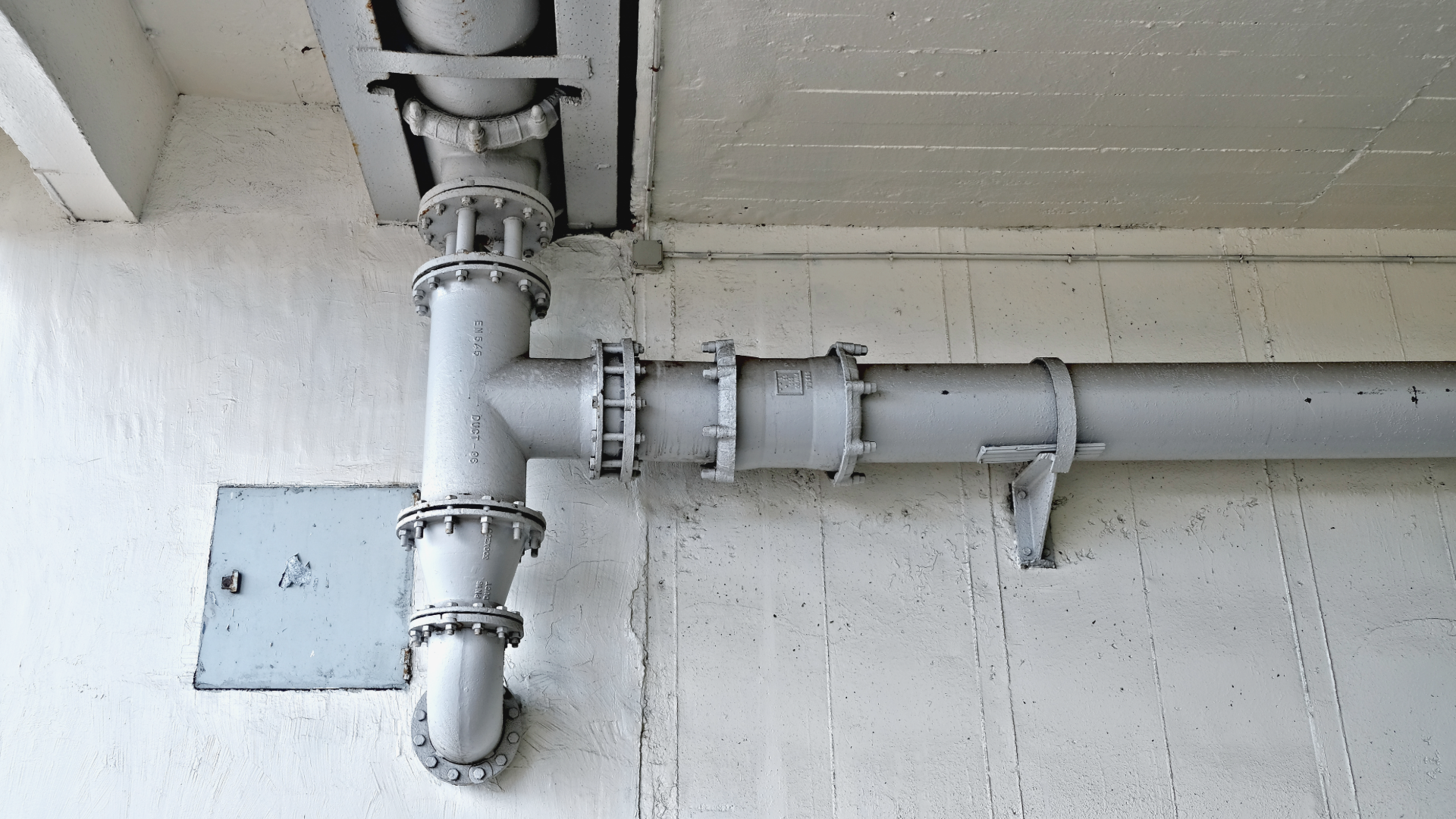

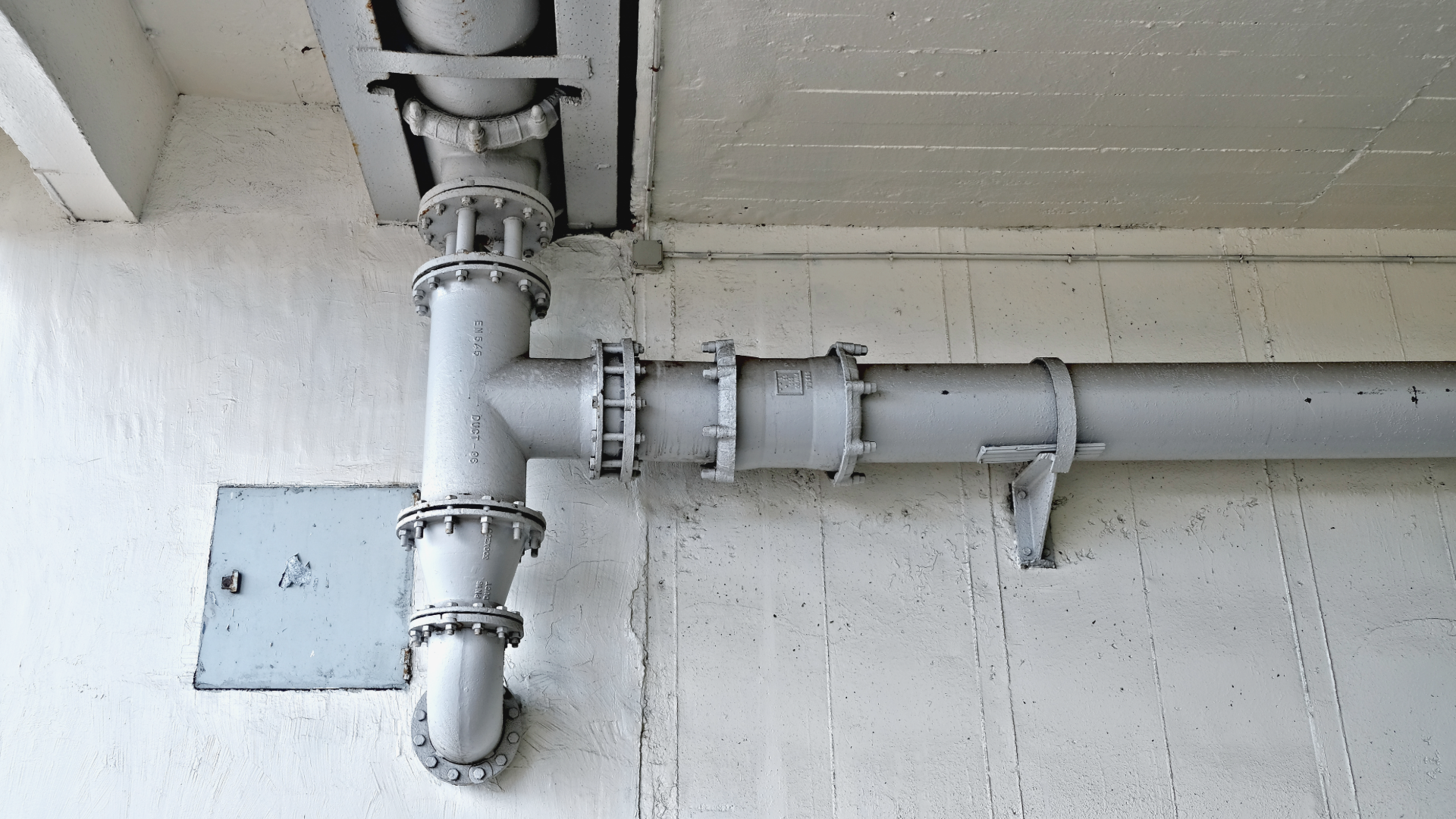

Municipal and Utility Systems

Link seals are a staple in public works projects. They are commonly used in:

- Water and Wastewater Treatment Plants: Seal pipe entries into tanks, treatment areas, and facilities to prevent leaks and contamination.

- Underground Vaults and Manholes: Protect utility lines from water infiltration and environmental exposure.

- Cased Road Crossings: Secure pipes passing under roadways to shield them from soil and moisture.

Industrial and Commercial Facilities

In commercial and industrial settings, maintaining system integrity is a top priority. Link seals are used for:

- Chemical Processing Pipelines: Provide leak proof seals for pipes carrying corrosive or hazardous materials between facility areas.

- HVAC and Cooling Systems: Maintain tight seals where mechanical or plumbing lines penetrate building walls and floors.

- Fire Protection and Power Generation: Ensure secure wall penetrations for various utility lines, including those requiring fire rated seals.

Specialized Installations

The unique properties of link seals also make them ideal for specialized environments, including:

- Data Centers and Telecom: Protect cooling lines and sensitive electrical and fiber optic conduits from moisture and environmental risks.

- Marine and Renewable Energy Sites: Withstand saltwater and harsh outdoor conditions ideal for docks, solar, and wind installations.

- Parking Garages, Basements, and Retaining Walls: Prevent water intrusion in high risk underground or exposed structures.

Link Seal Material and Product Options

Selecting the right link seal depends on the specific environmental conditions of your project. PVC Pipe Supplies offers options for both hardware and rubber sealing elements to match your application needs.

Hardware Options

The bolts and nuts that compress the links are available in two primary materials:

- Carbon Steel with Zinc Dichromate Coating: This is an economical and reliable choice for most standard applications, particularly in dry or controlled environments where chemical or water exposure is minimal.

- 316 Stainless Steel: For maximum corrosion protection, 316 stainless steel hardware is the ideal choice. It is recommended for high moisture environments, coastal areas, chemical applications, and direct burial installations.

Rubber Seal Element Options

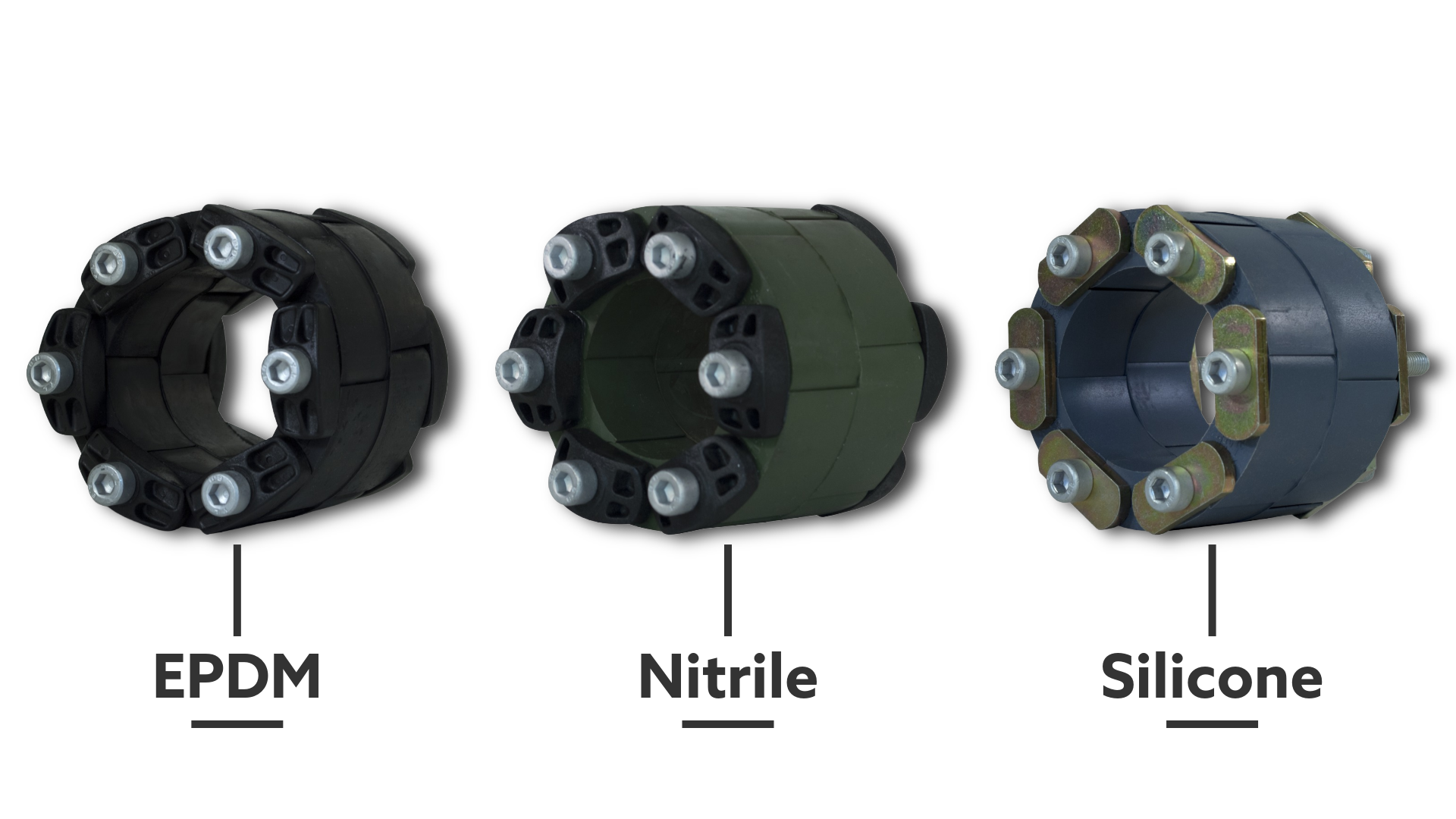

The rubber material of the link determines its resistance properties:

- EPDM (Black): This is the standard and most common material that offers excellent resistance to water and weather. It is suitable for a wide temperature range and is NSF 61 certified for compliance with potable water systems.

- Nitrile (Green): When an application involves potential exposure to oils, fuels, solvents, or other hydrocarbons, nitrile rubber is the recommended choice due to its superior chemical resistance against many of these materials.

- Silicone (Gray): For high temperature applications or where a fire rated seal is required, silicone rubber provides the necessary performance that is capable of withstanding extreme temperatures and maintaining a secure seal.

How to Select and Install Link Seals

Proper sizing and installation are key to achieving a reliable, long lasting junction with link seals. Here are a few tips on how to select and install link seals.

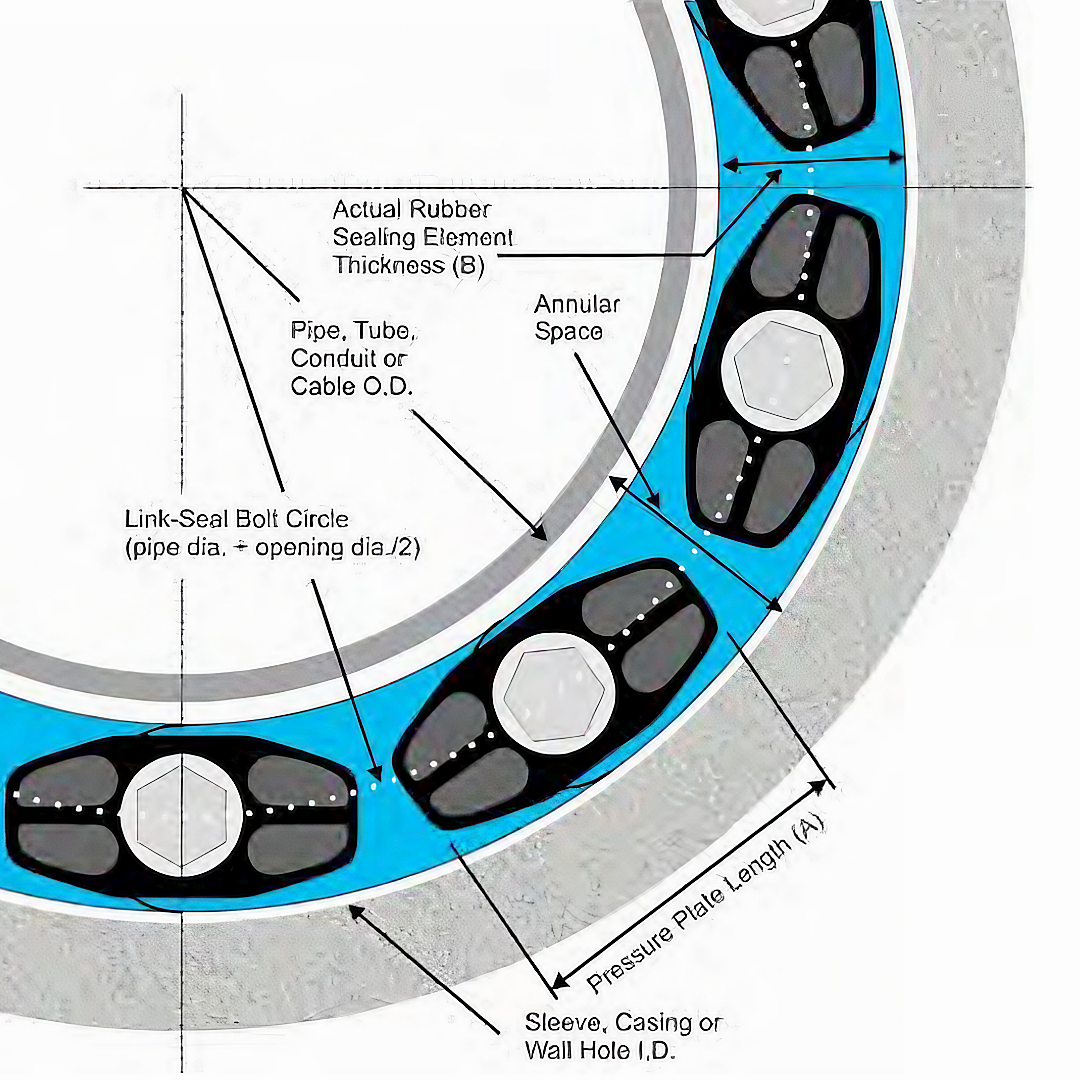

How to Select the Right Link Seal

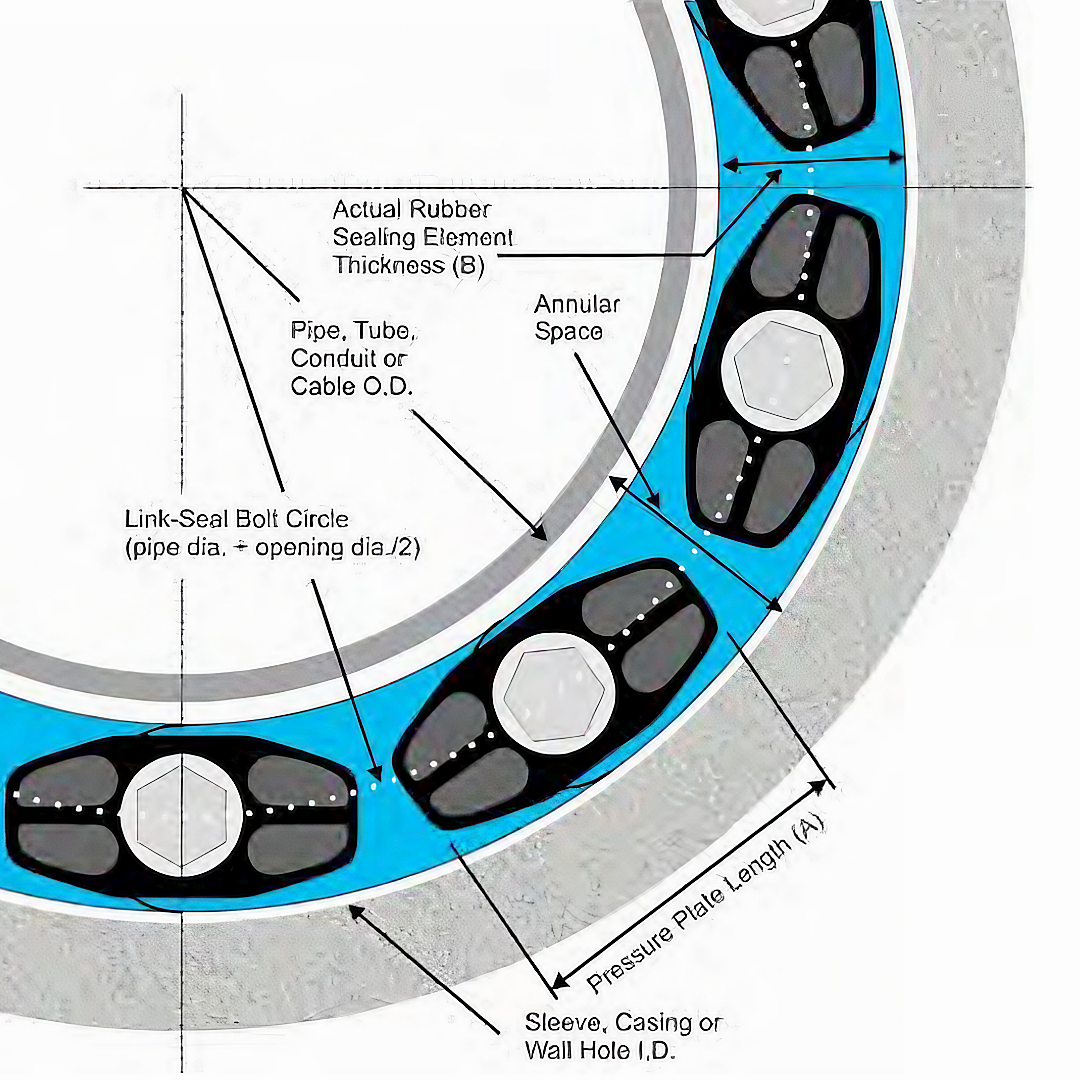

- Measure Diameters: First, accurately measure the pipe’s outer diameter (OD) and the inner diameter (ID) of the wall penetration or sleeve.

- Determine Annular Space: Calculate the annular space, which is the difference between the hole ID and the pipe OD, divided by two. This space determines the correct link size needed.

- Consult a Sizing Chart: Use a Link Seal Sizing Chart to match your measurements with the appropriate link seal model. The chart will also specify the exact number of individual links required to create a complete seal for your pipe diameter.

Installation Steps

- Assemble the Belt: Connect the required number of links to form a belt, ensuring it is correctly sized to fit snugly around the pipe.

- Position the Assembly: Place the link seal belt around the pipe and slide it into the annular space between the pipe and the wall opening.

- Tighten the Bolts: Using a hand wrench, tighten the bolts in a staggered, crisscross pattern, similar to tightening lug nuts on a wheel. This ensures even compression and pressure distribution to create a uniform and secure seal.

- Adjust for Angle: If the wall sleeve, such as the century line wall sleeve, is not or is not capable of being made perfectly square to the building wall, link seals can still be installed and perform as needed. Adjust subsequent pipe sections to account for any off angles and achieve a secure and watertight seal.

The Trusted Solution for Pipe Penetrations

Link seals are a proven, modern solution for creating durable and reliable seals in plumbing and piping systems. Their combination of easy installation, long term durability, and versatility makes them a trustworthy component for protecting infrastructure in residential, commercial, and industrial projects.

Explore the complete selection of carbon steel and stainless steel link seals at PVC Pipe Supplies. Find the perfect solution for your next project. For expert guidance or help with sizing, don’t hesitate to contact our team today.